Scratch Resistant & Abrasion Resistant Acrylic

Top Supplier of Scratch Resistant Acrylic Sheet

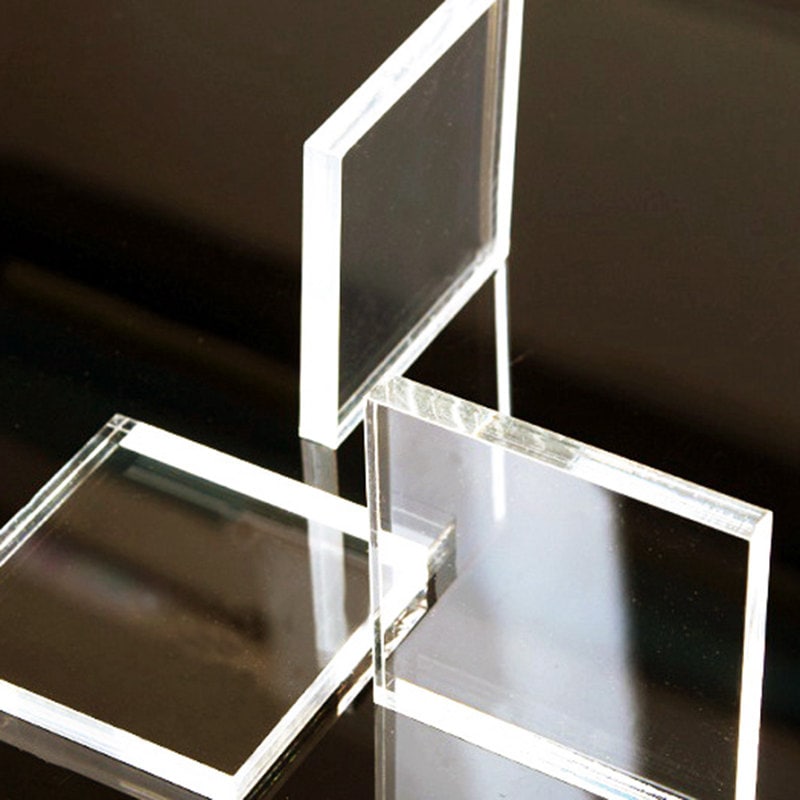

Scratch-resistant acrylic is designed to offer higher surface hardness for greater resistance to scratch and chemicals, the surface hardness is up to 4H or higher. Someone calls it “Scratch-resistant plexiglass”. Compared with plexiglass sheets, scratch-resistant plexiglass also provide better resistance to scratch and chemicals. The standard thickness is from 0.4mm to 12mm, and the Max thickness is up to 25mm. It is easy to cut, and silk-screen print. Therefore, it is an ideal material for the protective panel of the display screen, acrylic jewelry boxes, signs, furniture, picture frames, and POP display.

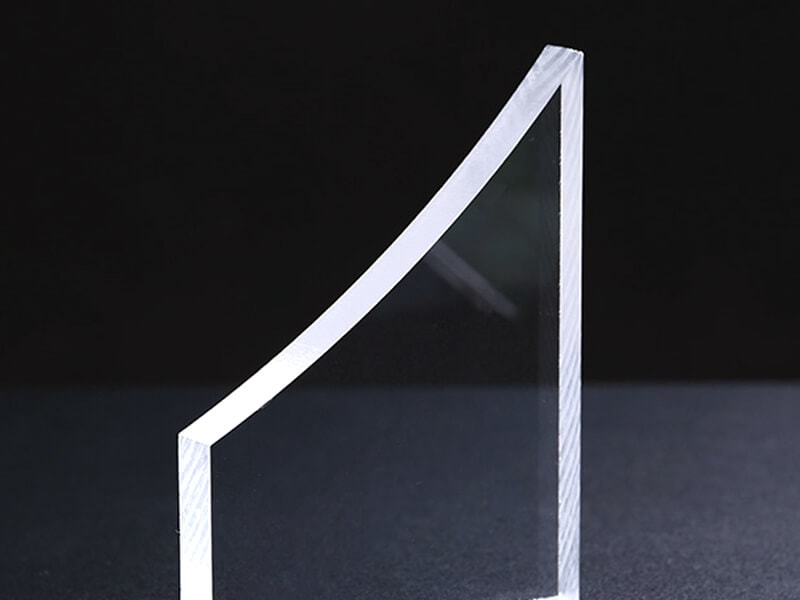

Abrasion Resistant Plexiglass is also named “mar-resistant plexiglass”, it is manufactured by coating on a regular plexiglass sheet, therefore, it offers better abrasion resistance, chemical resistance, UV resistance, and optical clarity. UVACRYLIC AR plexiglass can be hot-bending and It is used for safety glass, laminated glass, bus windows, automotive sunroofs, etc.

As the top supplier of scratch-resistant and abrasion-resistant acrylic sheets in China, UVACRYLIC uses two technologies to manufacture it, “coating technology” and “changing the performance of raw material”. Otherwise, UVACRYLIC provides an integrated machining solution to global clients.

Scratch Resistant Acrylic Specification

Product Range

| Model | Product Name | Thickness/mm | Standard Size/mm | Application |

|---|---|---|---|---|

| UVAC-HC-SR1 | One-side Scratch Resistant Acrylic | 0.4mm, 0.5mm, 0.65mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | 1200*1660 mm 1170*1810mm | Electronic displays, POP displays, LCD screens, furniture, acrylic mirror, kitchen splashback |

| UVAC-HC-SR2 | Two-side Scratch Resistant Acrylic | 0.4mm, 0.5mm, 0.65mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm | 1200*1660 mm 1170*1810mm | Wall signs, wayfinding board, interior partition |

| UVAC-HC-AR1 | One-side Abrasion Resistant Acrylic | 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8mm, 10mm, 12mm | 1300*2440mm 1220*2440 mm | Laminated glass, sign, |

| UVAC-HC-AR2 | Two-side Abrasion Resistant Acrylic | 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8mm, 10mm, 12mm | 1300*2440mm 1220*2440 mm | Bus windows, automotive sunroofs, Marine Portholes |

What You Need To Know

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density | g/cm^3 | 1.19 |

| Light transmittance | % | >90 |

| Taber Haze (CS-10F, 100 cycles) | % | 1-5 |

| Taber Haze (CS-10F, 500 cycles) | % | 3-8 |

| Taber Haze (CS-10F, 1000 cycles) | % | 10 |

| Pencil hardness | >4H | |

| Tensile Strength | Mpa | >70 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | KJ/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittance | % | >90 |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

Note: If you have a custom requirement, please send an email to [email protected]

Main Benefits

Physical Properties

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly