Machining Custom Acrylic

From Designing to Manufacturing, OEM&ODM…

Top Factory of Machining Custom Acrylic In China

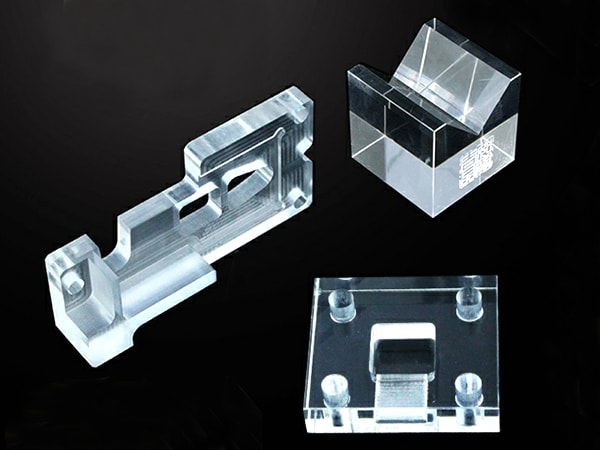

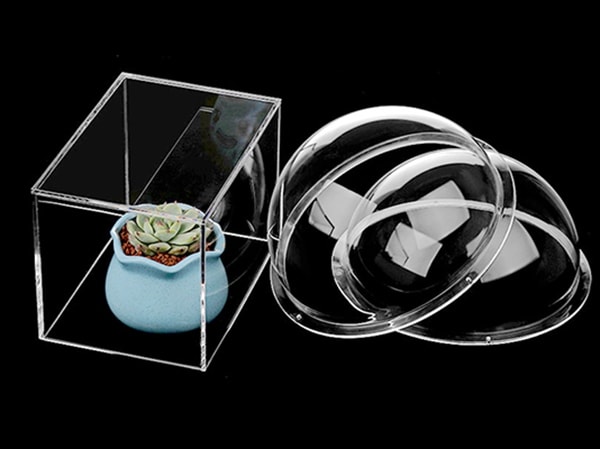

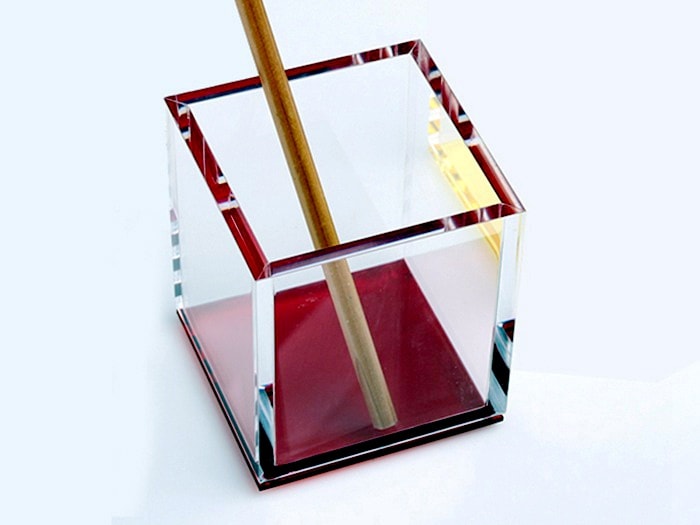

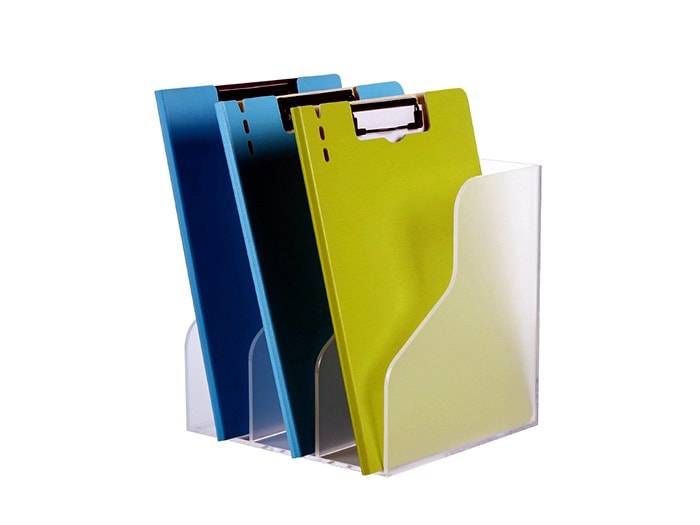

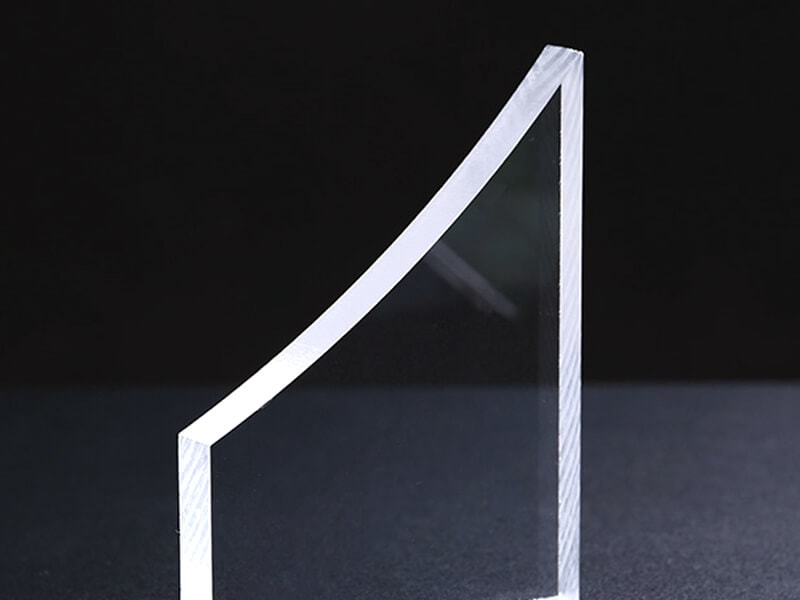

UVACRYLIC began to machine acrylic sheets in 2004. With continuous investment in production equipment and processing technology, we have grown to be the leading supplier of Custom Acrylic-based Products in China and provide the integrated machining solutions including cutting, bending, CNC Machining, surface finishing, thermoforming, printing, gluing. Meantime, UVACRYLIC has experienced engineers, who will design acrylic products according to clients’ requirements by CAD and Solidworks. Therefore, UVACRYLIC is one of the companies, which can design and manufacture it with a cost-efficient machining solution.

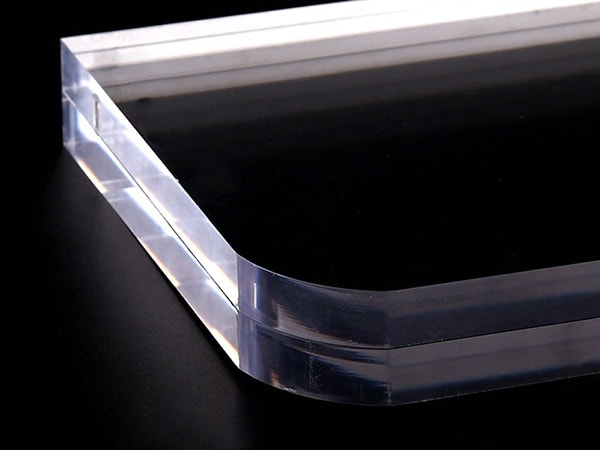

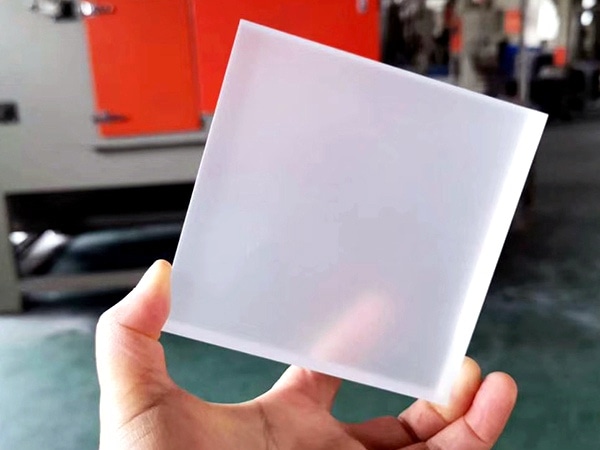

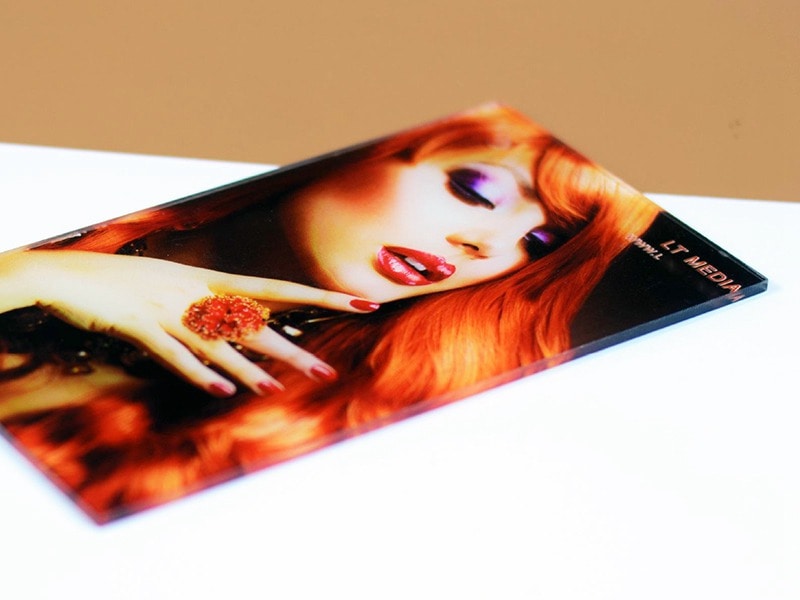

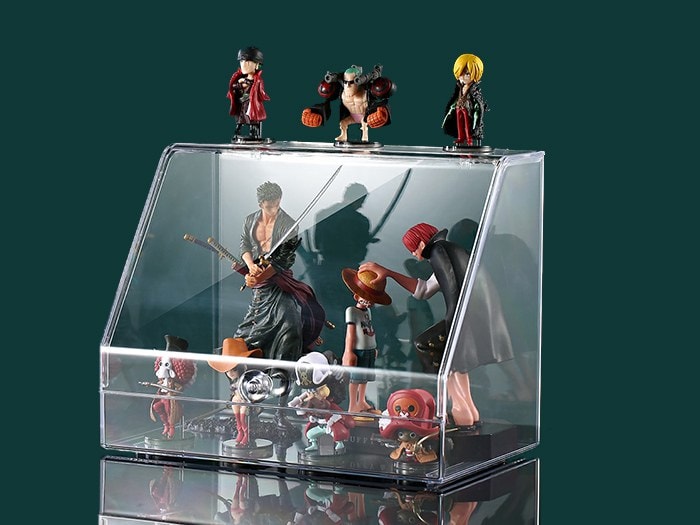

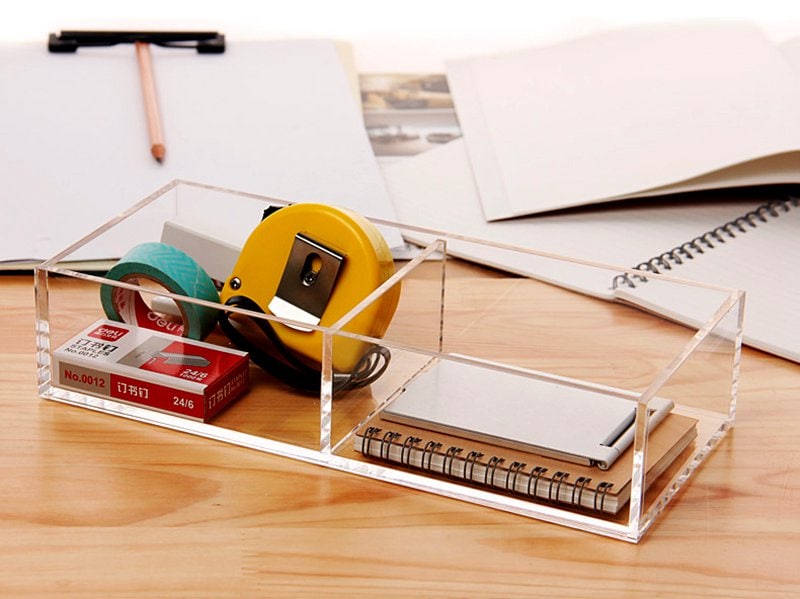

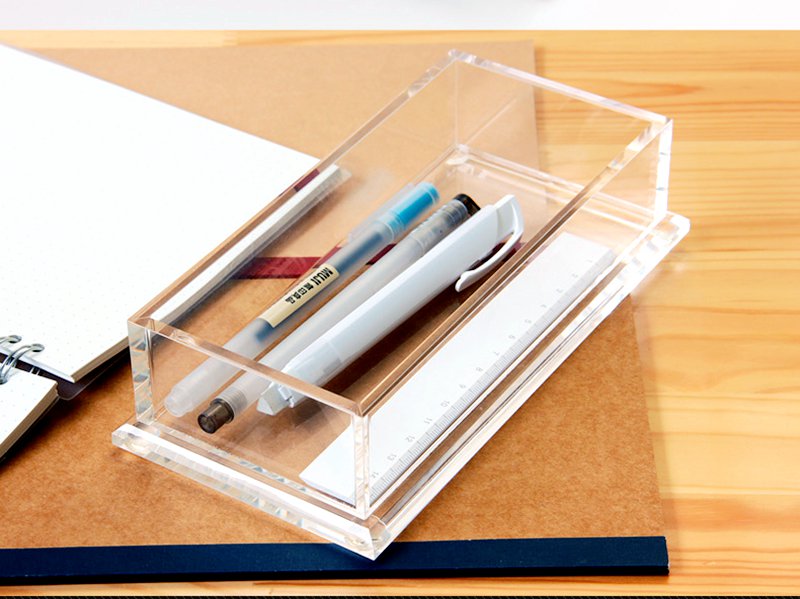

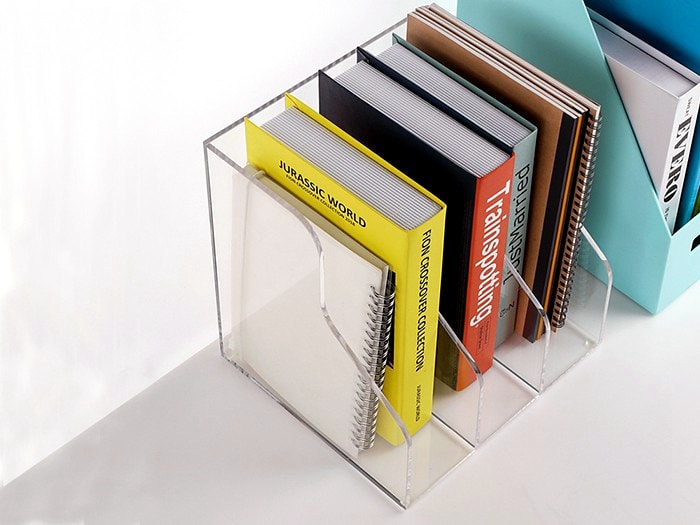

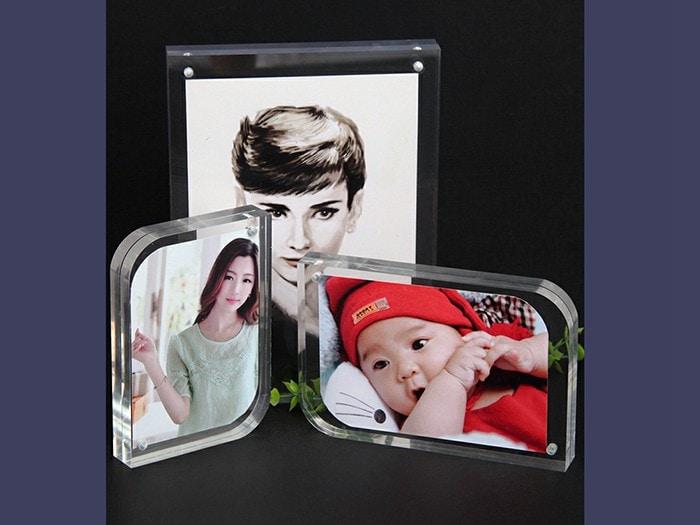

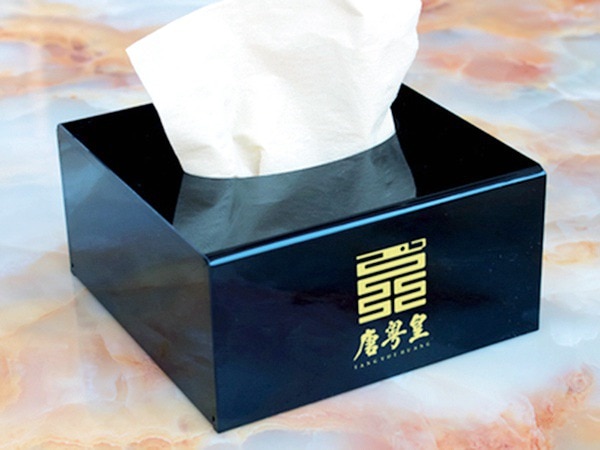

In 2007, UVACRYLIC built the factory to manufacture acrylic sheets including case and extruded sheets, thickness from 1mm to 400mm. With more than 13 years of experience in manufacturing acrylic sheets and 16 years of experience in machining acrylic, UVACRYLIC knows more about machining acrylic. Today, we are so honored to provide high-quality acrylic products to more than 700 clients all over the world, they are active in the display industry, home decoration, office supplies, automation, medical device, printing industry, etc.

Machining Solution

With more than 17 years of experience in the acrylic field, we have a better understanding of machining acrylic from designing to the final acrylic-based products by the most cost-efficient machining solution. Here are some machining methods for custom acrylic.