Best Anti-Static/ESD Acrylic

Thickness from 1.5mm to 30mm, Cut to size…

Top Supplier of Anti-Static/ESD Acrylic Sheet

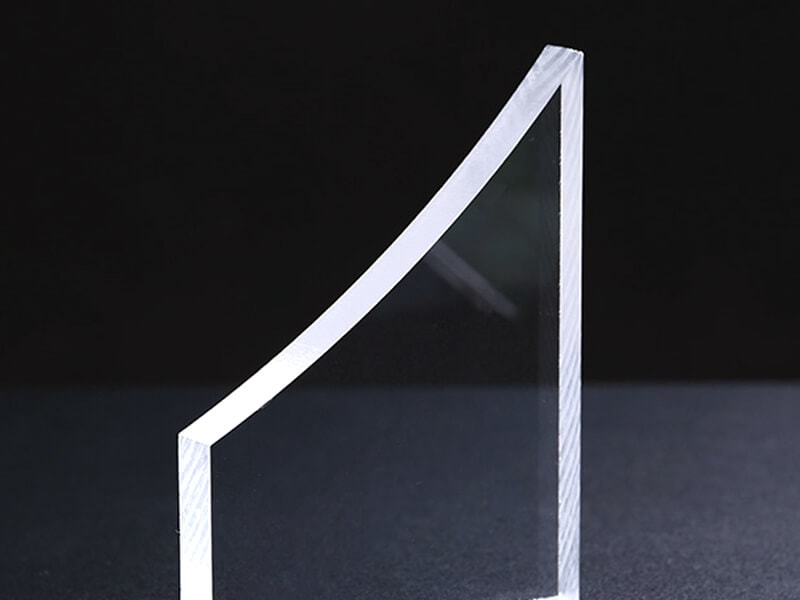

Anti Static Acrylic or ESD Acrylic Sheets are the short names of the electrostatic dissipative acrylic/plexiglass sheet with surface resistance from 10^6 to 10^8 Ohms. It is designed to prevent static generation and particulate attraction on surfaces and reduce static electricity to protect electrostatic-sensitive devices (ESD) or contain flammable liquid or gas.

It is a high-quality acrylic sheet that has been coated with a permanent or semi-permanent anti-static coating with transparent color that isn’t affected by humidity. Therefore, it offers excellent chemical resistance and surface hardness.

Anti Static Acrylic is the right material for a dust-free laboratory, static control shields for machinery, Instrument box, semiconductor device, and medical device.

UVACRYLIC is a leading manufacturer of acrylic sheets and a provider of ESD coating services in China. The acrylic sheets are made of virgin raw material, purchased from Lucite and Mitsubishi company. Therefore, the quality is high and stable. Today, we are providing excellent ESD acrylic sheets to more than 600 clients from 40 countries.

Anti-static/ESD Acrylic Specification

Standard Dimensions

| Model | Product name | Thickness | Size in Metric System | Size in British System |

|---|---|---|---|---|

| UVAC-ESD-E | Economic Anti-Static/ESD Acrylic | 0.8mm, 1mm, 2mm, 3mm, 5mm, 6mm, 8mm | 1220x2440mm | 4x8ft |

| UVAC-ESD-D | Durable Anti-Static/ESD Acrylic Sheet | 1.5mm, 2mm, 3mm, 4mm, 5mm, 8mm, 10mm, 15mm, 20mm, 25mm | 1220x2440mm | 4x8ft |

What You Need To Know

Electrical Resistance Property

| Electrical Resistance Property | Test Method | Unit | Value |

|---|---|---|---|

| Surface resistance | ASTM D257-14 | Ohms | From 10^6 to 10^8 |

| Friction voltage | Volt | <100 |

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density (clear acrylic) | g/cm^3 | 1.19 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittance | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

| Light transmittance | % | >90 |

Main Benefits

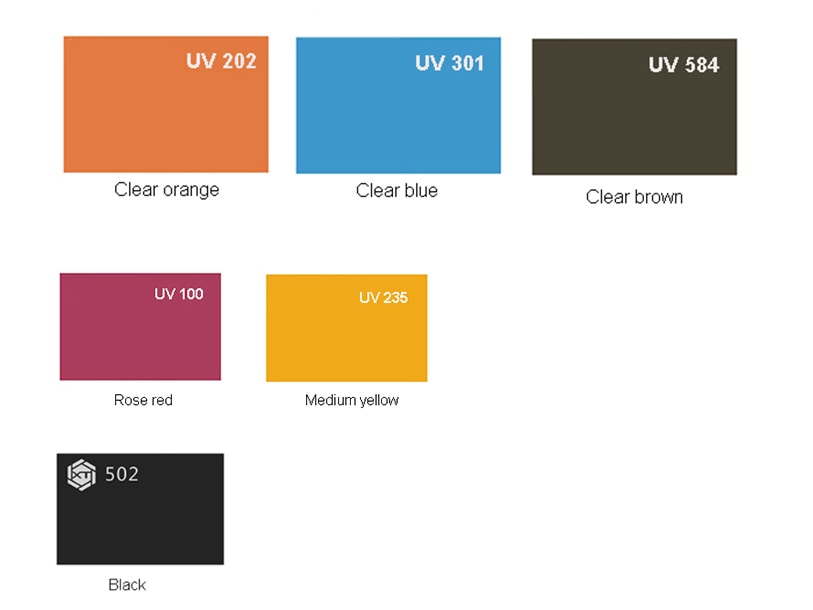

Colors Range of ESD Acrylic Sheet

| Color | Description |

|---|---|

| Transparent color | Clear, clear orange(UV202), clear blue(UV301), clear brown(UV584) |

| Translucence color | Rose Red(UV100), Medium Yellow (UV235) |

| Opaque color | Black (UV502) |

Main Applications

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly