Best Non-Glare Plexiglass/Acrylic

Best material for picture frames at museums and viewing screens…

Top Supplier of Non-Glare Plexiglass/Acrylic in China

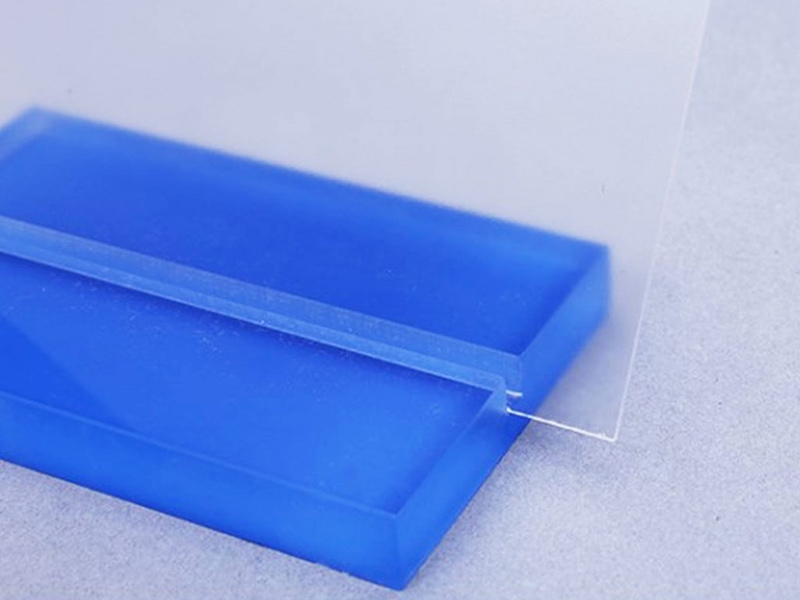

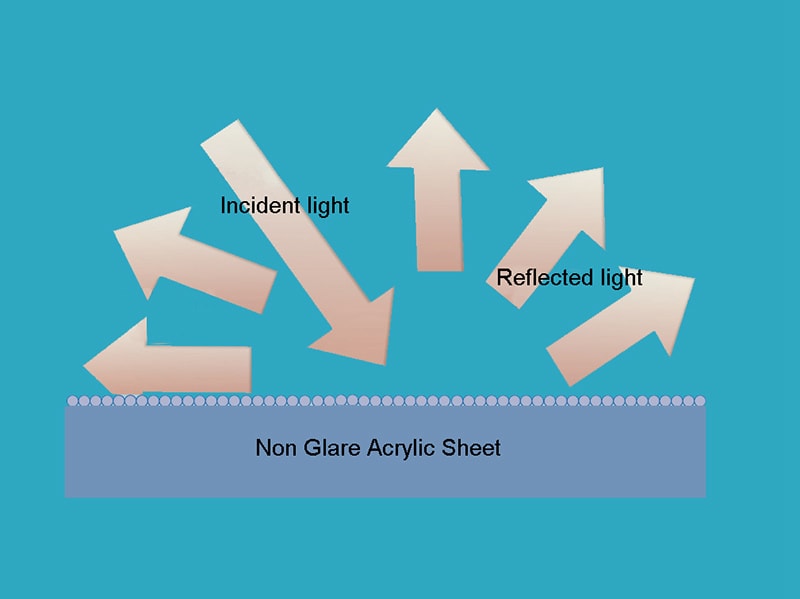

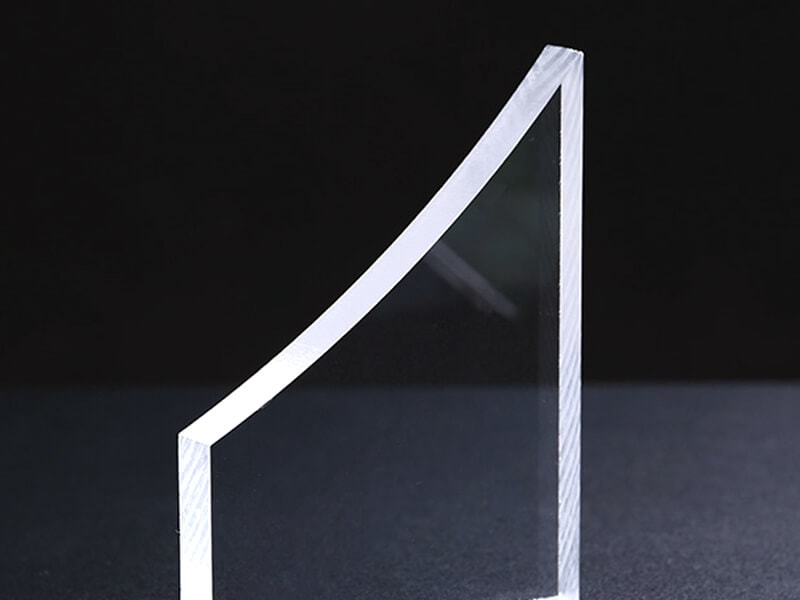

Non Glare plexiglass/Acrylic is designed to minimize glare and reflection with a matte finish, it creates a glare-free view from any angle, but the physical properties are the same as the standard plexiglass sheet. It is also named “Anti Glare Acrylic”, “non-glare plastic” or “anti-reflective Plexiglass/Acrylic” in some countries.

Non-glare plexiglass/acrylic offers a clearer and more saturated color while viewing art photos, therefore, it is the best material for picture frames at a gallery, museum, home, and more. Otherwise, non-glare plexiglass is also used as a protector for viewing screens, and signs board in public places.

UVACRYLIC is a leading manufacturer of non-glare acrylic in China, we use high-quality raw materials to manufacture plexiglass sheets, and coat them for different products. Otherwise, we can print or silk-screen on non-glare acrylic according to the drawings in a variety of applications. Today, we are providing products made of non-glare plexiglass to more than 1200 clients from 40 countries, including picture frames, protectors for viewing screens, signs, and small parts.

Non-Glare Acrylic Specification

Product Range of Non-glare Plexiglass

| Model | Haze (%) | Thickness (mm) | Sizes (mm) | Application |

|---|---|---|---|---|

| UVAC-NG-H | >40% | 0.8; 1; 1.5; 2; 3; 4; 6; 8; 10; | 1200 x 2440 | Protector for viewing screen, instrument panel, and other devices with backlight |

| UVAC-NG-M | From 20% to 30% | 0.8; 1; 2; 3; 4; 6; 8; 10; 12; 15 | 1200 x 2440 | Glazing materials for picture frames, artwork frames, museum glass, etc; |

| UVAC-NG-L | <20% | 0.8; 1; 2; 3; 4; 6; 8; 10; 12; 15 | 1200 x 2440 | Sign, acrylic labels, wall signs and wayfinding board, etc. |

What You Need To Know

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| HAZE | % | From 10% to 60% |

| Density | g/cm^3 | 1.19 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

| Light transmittance | % | >90 |

Application of Non-glare Plexiglass

Main Benefits of Non-Glare Plexiglass

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly