Plexiglass/Acrylic In All Forms

Clear Sheet, Colored Sheet, Coated Sheet, Film, Block…

UVACRYLIC™ Acrylic/Plexiglass Sheets

Brief Introduction Of UVACRYLIC™ Acrylic Sheets

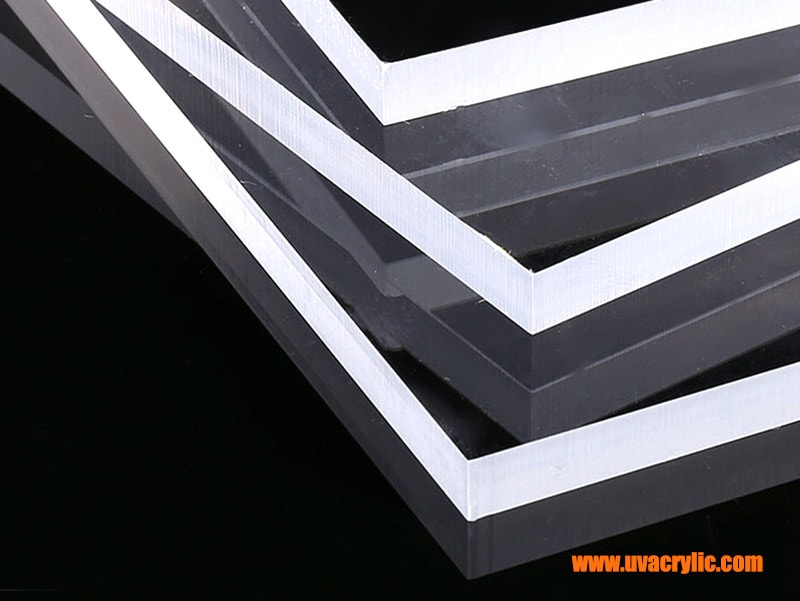

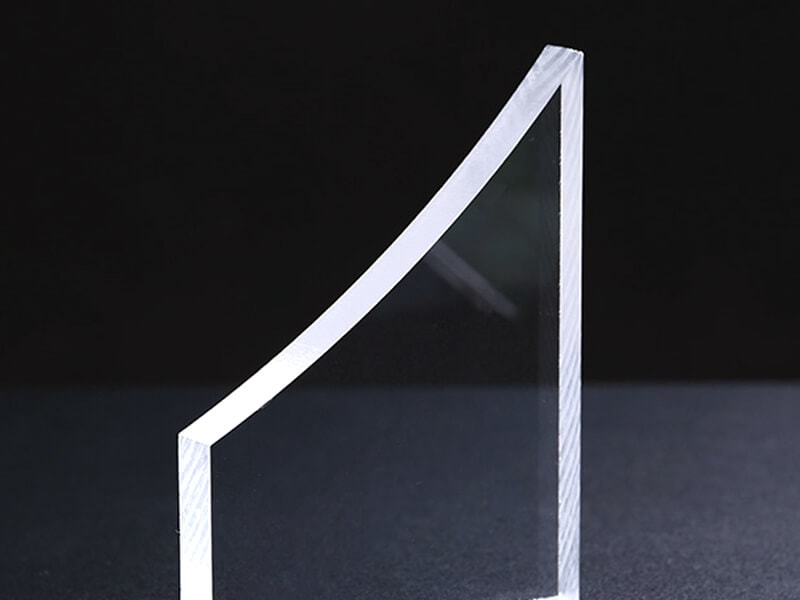

Acrylic sheet is one of the thermoplastic sheets, which is made of polymethyl methacrylate (PMMA), it is well known by the trade name “plexiglass sheet“. It is a versatile plastic sheet with a variety of purposes and benefits, which is produced according to the extrusion process and casting process, therefore, some people call it as “extruded acrylic sheet” and “cast acrylic sheet”. This material is similar to polycarbonate sheets, but better price and surface hardness, and lower impact strength.

Acrylic sheet was first produced in 1928 and was brought to market by Rohm and Haas Company in 1933. In the very beginning, it is used as airplane windows, turrets, and canopies during the Second World War. Today, the acrylic sheet has become to be the most commonly used plastic material in our daily life, such as security barriers, medical devices, furniture, POP display, office supplies, fish tank, etc.

Acrylic sheets are available in a wide range of thicknesses, colors and provide superior weather ability. Otherwise, it offers new functions by coating layers, for example, higher surface hardness, better abrasive resistance, mirror surface, anti-static and non-glare functions.

UVACRYLIC™ is a leading manufacturer of acrylic in China, the annual production capability is over 12 thousand tons, meantime, we provide integrated machining service. Our all raw materials are from Mitsubishi and Lucite, and with the strict quality management system, our all acrylic sheets are high-quality and environment-friendly. Today, we are honored to supply high-quality acrylic-based products and integrated machining services to more than 1200 clients from 40 countries.

UVACRYLIC™ Plexiglass Specification

Acrylic Sheet

| Item | Model | Thickness (mm) | L x W (mm) | L x W (Ft) |

|---|---|---|---|---|

| Extruded Acrylic | UVAC-EX | From 0.8mm to 20mm | 1220 × 2440, 3000 × 2000, Custom Size | 4 x 8, Custom Size |

| Cast Acrylic | UVAC-CA | From 1.8mm to 50mm | 1220 × 2440, 3000 × 2000 | 4 x 8 |

| Clear Acrylic | UVAC-CLE/C | From 0.8 mm to 50 mm | 1220 × 2440, 3000 × 2000 | 4 x 8 |

| Colored Acrylic | UVAC-CO | From 0.8 mm to 50 mm | 1220 × 2440, 3000 × 2000 | 4 x 8 |

| Acrylic Diffuser | UVAC-DI | 1 mm, 1.5 mm, 2 mm | 1220 x 1830, 1220 x 2440 | 4 x 8 |

| Acrylic Film | UVAC-T | 0.075mm | Length is 1000 Meters Width is 1.28 Meters | / |

| Acrylic Block | UVAC-BL | From 51mm to 500mm | 1220 × 2440, 3000 × 2000 | 4 x 8 |

Acrylic Rod/Tubing

| Item | Model | Diameter (mm) | Standard Length (mm) | Standard Length (ft) |

|---|---|---|---|---|

| Acrylic Rod | UVACR | From 2 mm to 400 mm | 2000mm, Custom Length | 2ft, 3ft, 4ft, , Custom Length |

| Acrylic Tube | UVACT | From 2.5 mm to 1000 mm | 2000mm, Custom Length | 2ft, 3ft, 4ft, , Custom Length |

Coated Acrylic Sheet

| Item | Model | Thickness (mm) | L x W (mm) | L x M (Ft) |

|---|---|---|---|---|

| Acrylic Mirror | UVAC-MI | 0.8mm, 1mm, 2mm, 3mm, 4mm, 5mm | 1220 x 2440 | 4 x 8 |

| Anti-Static Acrylic | UVFA-ESD | From 1mm to 20mm | 1220 x 2440 | 4 x 8 |

| Scratch Resistant Acrylic | UVAC-SR | From 1 mm to 20 mm | 1220 x 2440, 1380 x 2440 | 4 x 8, 4.5 x 8 |

| Non Glare Acrylic | UVAC-NG | 0.8mm, 1mm, 2mm, 3mm, 4mm, 6mm | 1220 x 2400 | 4 x 8 |

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density (clear arcylic) | g/cm^3 | 1.19 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittace | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

| Light transmittance | % | >90 |

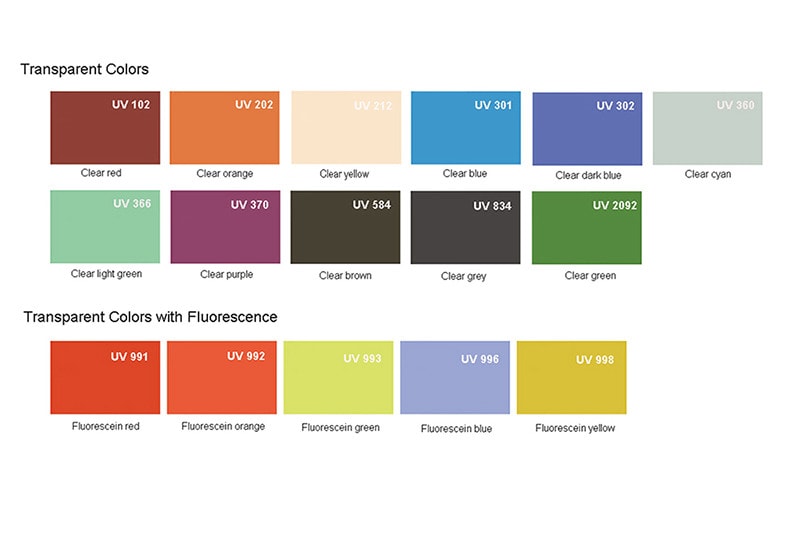

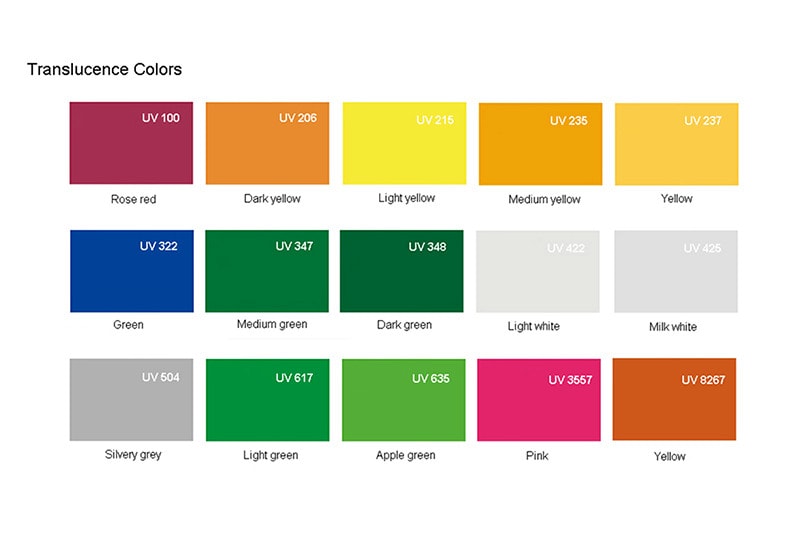

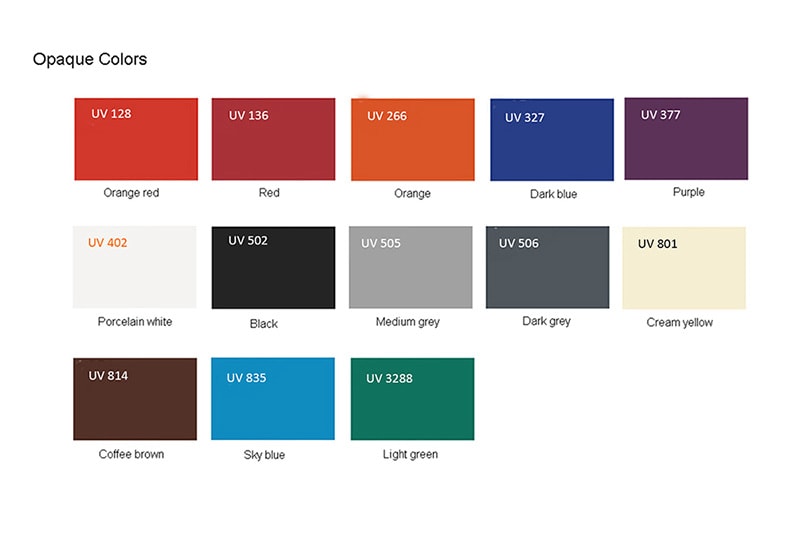

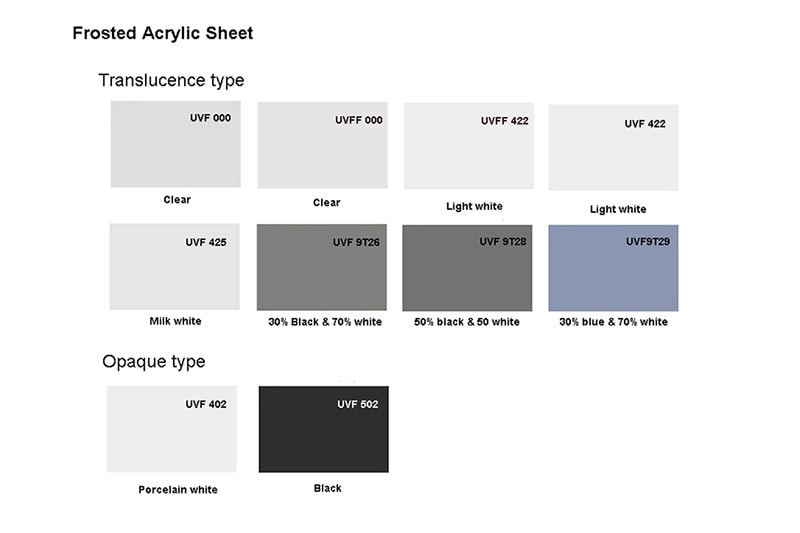

Colors Options

Machining Custom Acrylic Service

With More than 15 years of experience in machining acrylic, UVACRYLIC provides integrated machining solutions for custom acrylic. Today, we have grown to be the top OEM factory of acrylic-based products.

The common machining acrylic methods include cutting, polishing, bending, gluing, coating, CNC Machining, Printing, Drape forming, Injection Molding, Blow Molding, etc.

From common machining, methods, our engineer always find the right solution for all acrylic-based products.

Related Products And Machining Services

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly