Cast vs Extruded Acrylic: Which one is best for you?

Cast VS Extruded Acrylic: Ultimate Guide

Let’s say you have decided to buy the acrylic sheets. There’re two popular options for this product, extruded and cast acrylic sheets. Both of these sheets deliver great value for the users. But you need to find out which one suits you best. Unfortunately, you have no idea which of these will be better for you.

To find out which one fits you well, you need to ask yourself four questions:

And you’ll get answers to four questions in a bit.

Here we’ve explored both of these products with underlying pros and cons. The ultimate goal of this article is to help you decide which of the options suits you better than another. But before jumping into the details, you need to understand the basics.

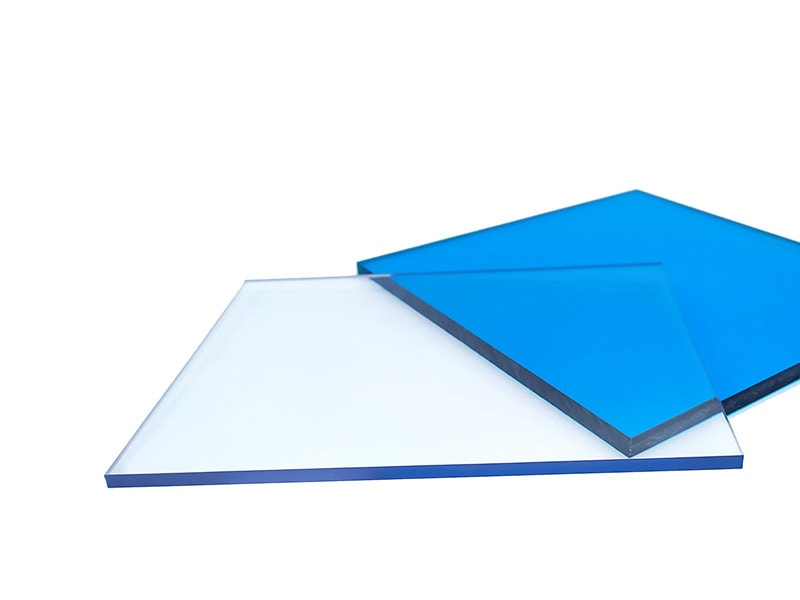

Acrylic Sheet

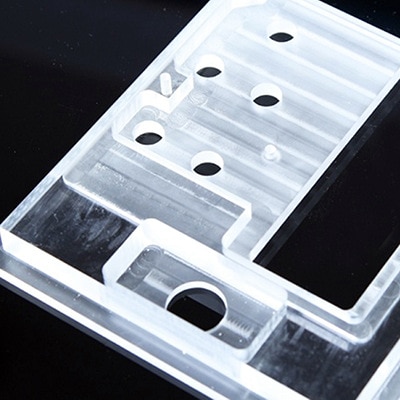

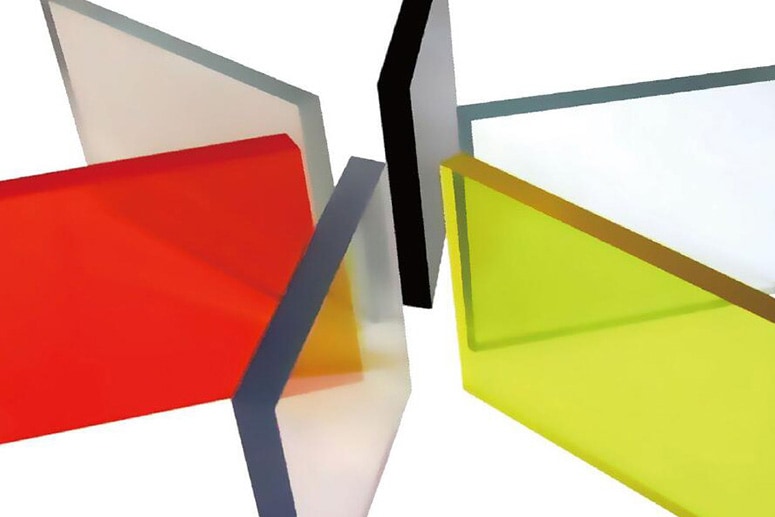

Acrylic or plexiglass sheets are wonderful alternatives to glass. It is a see-through thermoplastic homopolymer. These thermoplastic sheets are made by cast polymerization or extrusion. Hence the two different options exist.

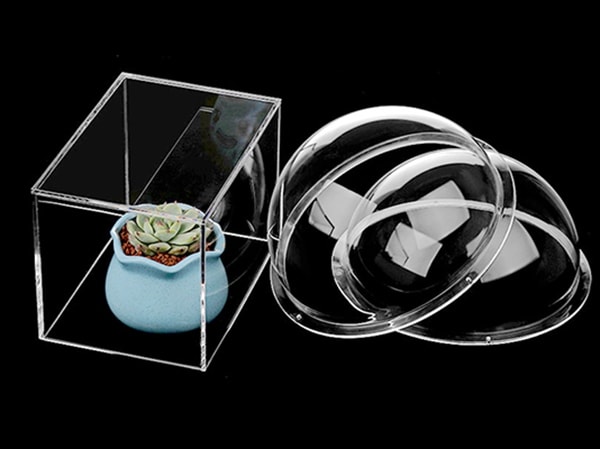

Acrylic sheets are widely accepted because of their undeniable applications. The resistance, durability, lightweight features make acrylic an excellent substitute for glass materials. They are widely used for skylight, greenhouse, windows, displays, lens, and so on.

So that’s an overview of the mother product. Now let’s dive into the actual comparison.

Difference Between Cast and Extruded Acrylic

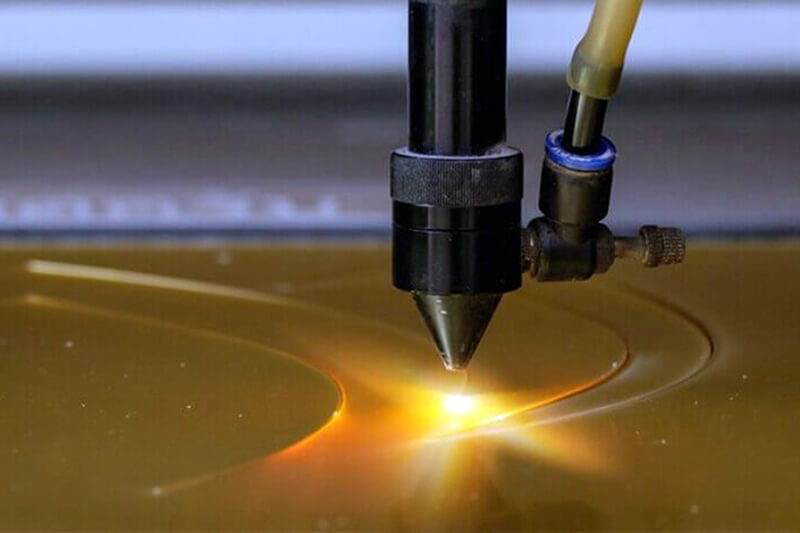

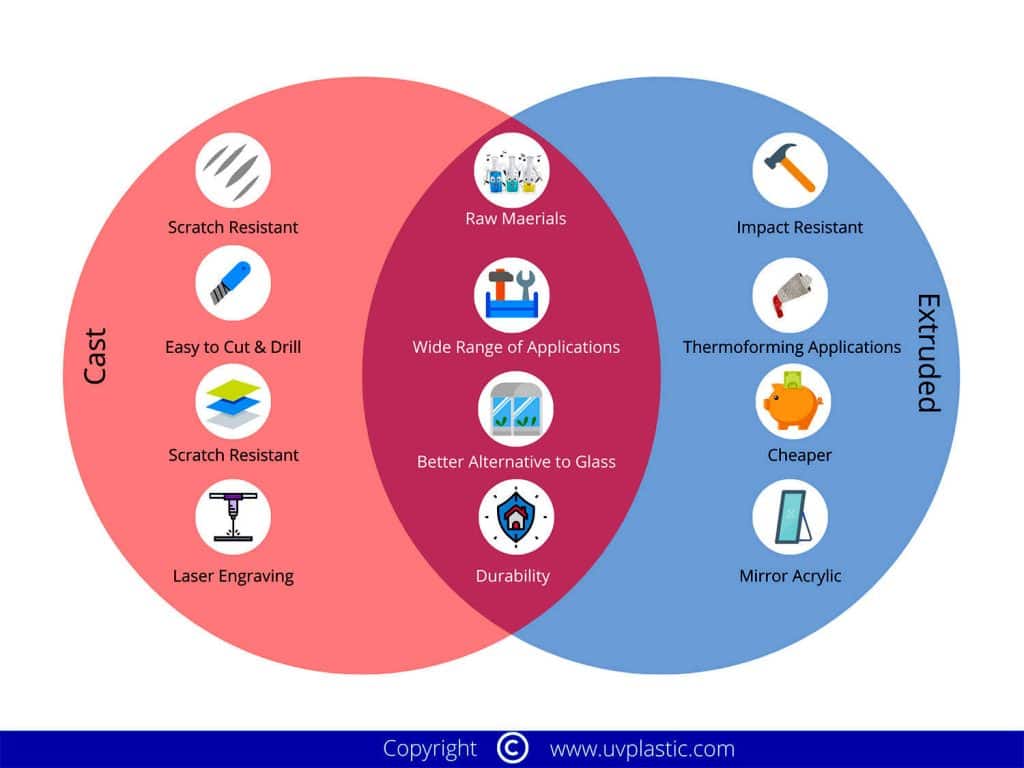

Both of these products are made out of the same materials but in two different ways, Casting and Extrusion.

The casting method is more expensive than the extrusion method. That is why extruded sheets are cheaper than cast sheets. Because of its manufacturing process, casting acrylic has a harder surface.

That makes it less likely to get scratch marks, although extruded acrylics are more impact resistant and an excellent choice for a lower budget.

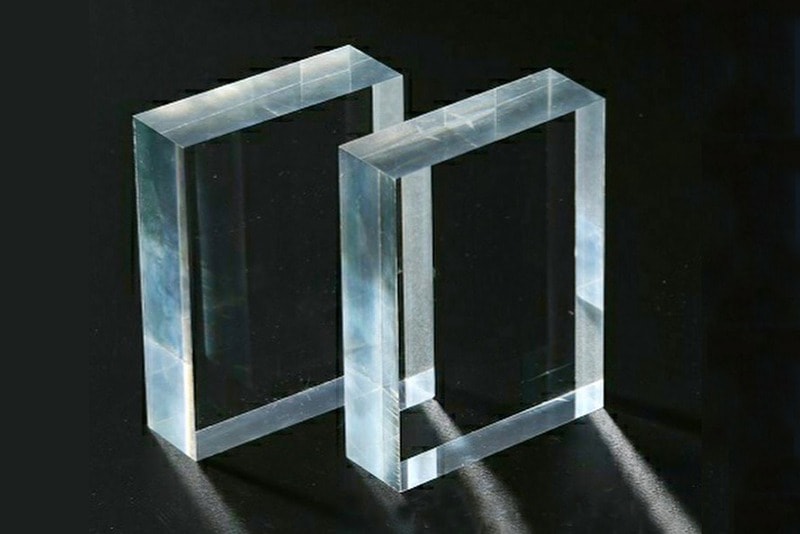

What is Cast Acrylic?

Cast acrylic is a roughly 95% polymerized sheet, which is made by polymerizing the MMA in between two layers of glasses. It’s a labor-intensive process.

The Manufacture Process

In our acrylic plant, we use two perfectly clean and smooth glass plates to make the mould. The size of the glass plates is slightly bigger than the actual acrylic sheet size.

These glass panels have space in between them. A silicone bead is placed around the mold, and then we pour the viscous materials inside of it.

Then these plates go into the oven and we start the healing process. It remains there for 10-12 hours before we start cooling them. After that, they are ready to mask and ship out to you.

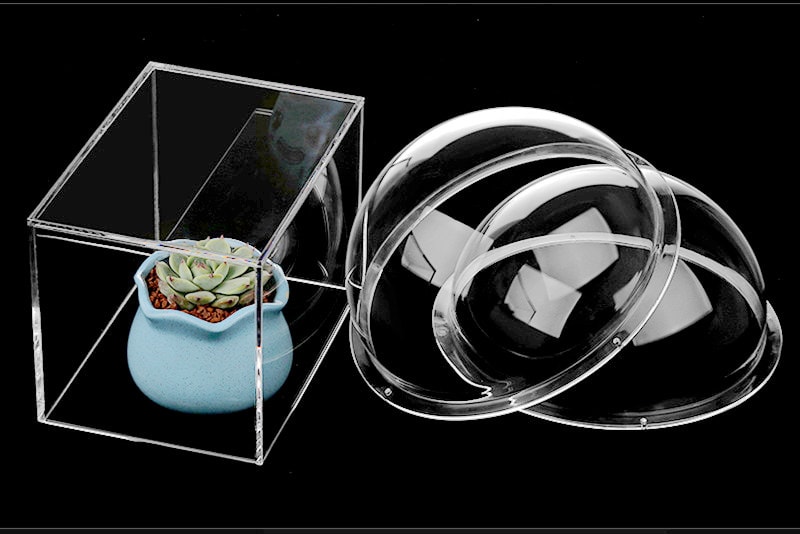

Normally, the colored acrylic sheet, acrylic block, ESD acrylic sheet are case acrylic sheets. The acrylic rod and acrylic tube with large diameter also case acrylic.

Advantages of Cast Acrylic

Related Products

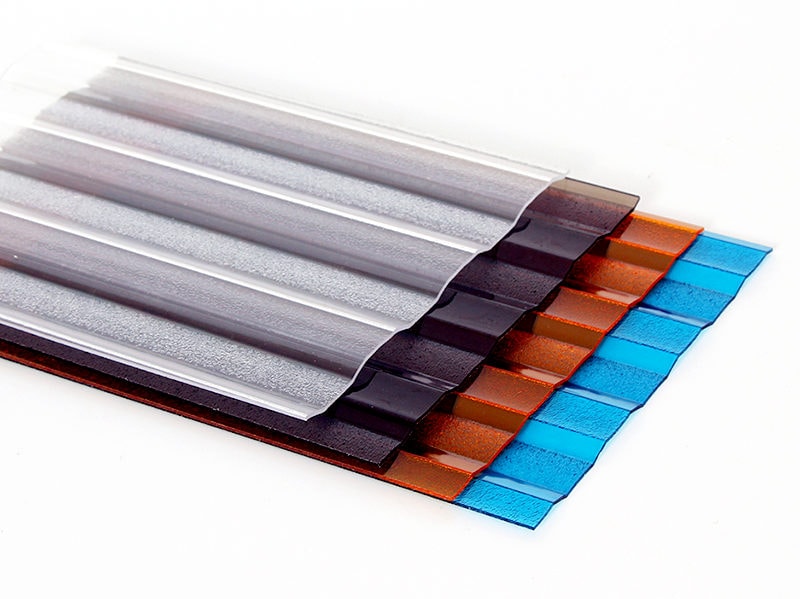

What is Extruded Acrylic?

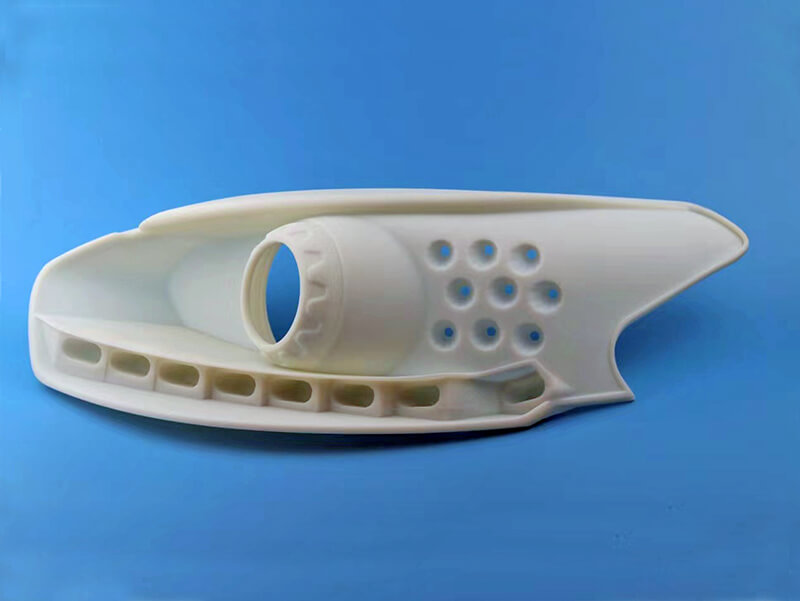

It is a roughly 90% polymerized sheet made with an automated process with machines.

The Manufacturing Process

In the extruded acrylic production process, we use state of the art machines, which are around 25/30 meters long.

We use the raw material that is already in PMMA form but in pallets. We enter those pallets at one end and instruct the machines about the size, thickness, color, and other specifications using computers. And then receive the outcome to another end.

Normally, the acrylic sheet with a thin thickness or acrylic film is an extruded sheet. Acrylic tube with a small diameter is extruded.

Advantages of Extruded Acrylic Sheet

Which One You Should Choose?

You can’t possibly go wrong with any of these sheet types. But to better match your needs and requirements, it’s time to answer those three questions.

1. Why do you need it?

-If you are buying this for a greenhouse, roofing, or aquariums, extruded sheets will work just great. You need this to be more impact resistant and dense. With products like awards, financial tombstones, trophies, corporate gifts, and other products that require shaping or machining, we prefer you to go with cast acrylic.

2. How much do you need?

-If your requirement is not much, casting might be a more excellent choice for you. And if you need these sheets in a higher volume, we suggest you go with extruded ones.

3. What is your budget?

-Cast acrylic manages to be more transparent and made to a higher degree standard, but in accomplishing so makes it more costly than extruded sheets. If you have a tight budget, extruded might be a better choice for you. And if the price is not a concern. You might choose the other one.

4. What is your requirement for thickness of thickness tolerance?

Normally, extruded acrylic sheet offers great thickness tolerance, but the thickness tolerance of cast acrylic sheet will be ±10% thickness. If some supplier told you that a cast acrylic sheet offers the same thickness as an extruded acrylic sheet. Maybe, they want to pretend extruded acrylic sheets to be cast acrylic sheets.

Final Question: How to find the right supplier?

Choosing between these two options is easy. The hard decision is choosing the right supplier for your desired products. If you choose the wrong manufacturers and get an average quality product, you can’t possibly have the desired outcome. Choose a supplier who can deliver the right size, thickness, colors, or any other requirement that you have.

Why would UVPLASTIC be an excellent Supplier for you?

Here at UVPLASTIC, we care about our clients and partners. Our ultimate goal is to provide you with what you need, and how you need it. We are gracefully serving people all over the globe for the past 17 years. When you work with us, you get almost 18 years of experience and expertise.

We understand and care about your needs and supply the state of the art materials in a short period. Before you consider making a purchase decision, you can get any help from us by directly connecting with our customer care. And we’ll be happy to help you over the phone.

Otherwise, we can provide other acrylic sheets and coated PMMA sheets, such as acrylic block, acrylic diffuser sheet, anti static acrylic, non glare acrylic sheet, acrylic mirror sheet, etc.

And if you have any questions and requirements fill out this form, we’ll get in touch as soon as possible.