Leading Solid Polycarbonate Sheet Manufacturer In China

Best Solid Polycarbonate you could find

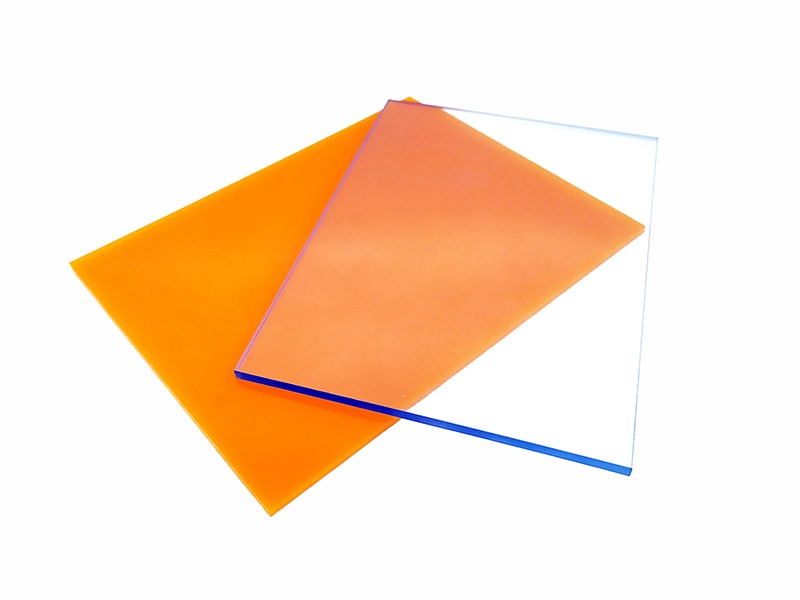

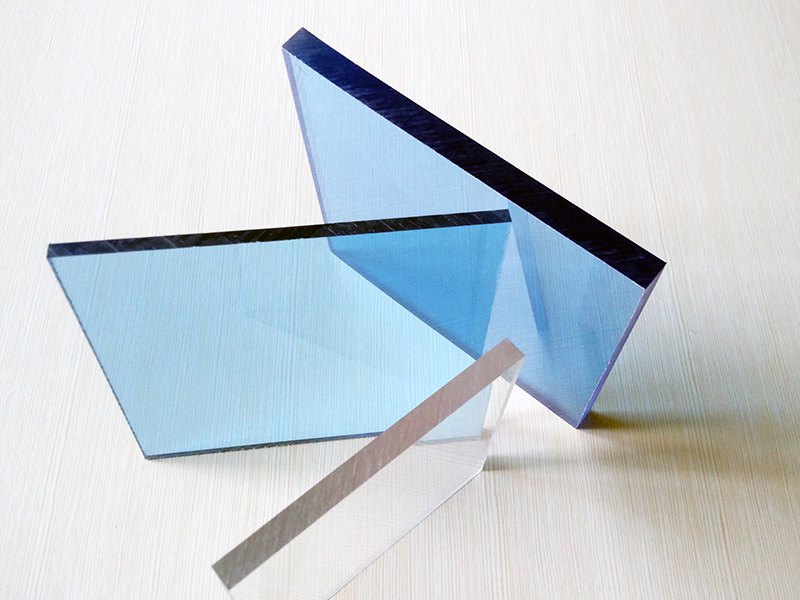

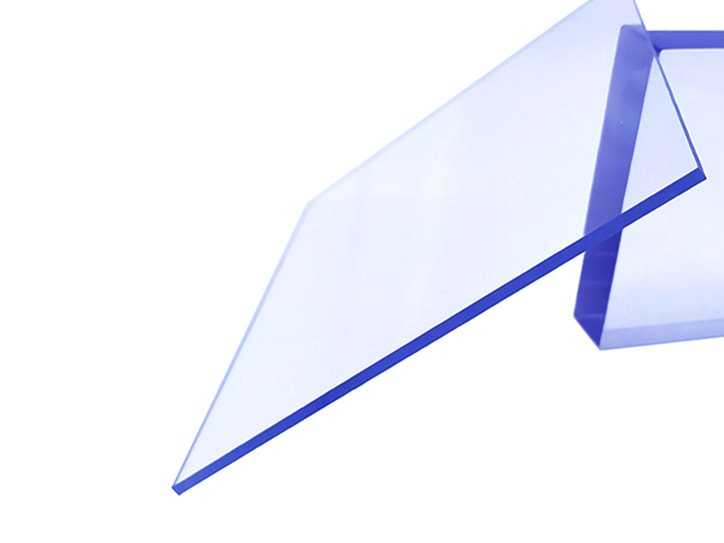

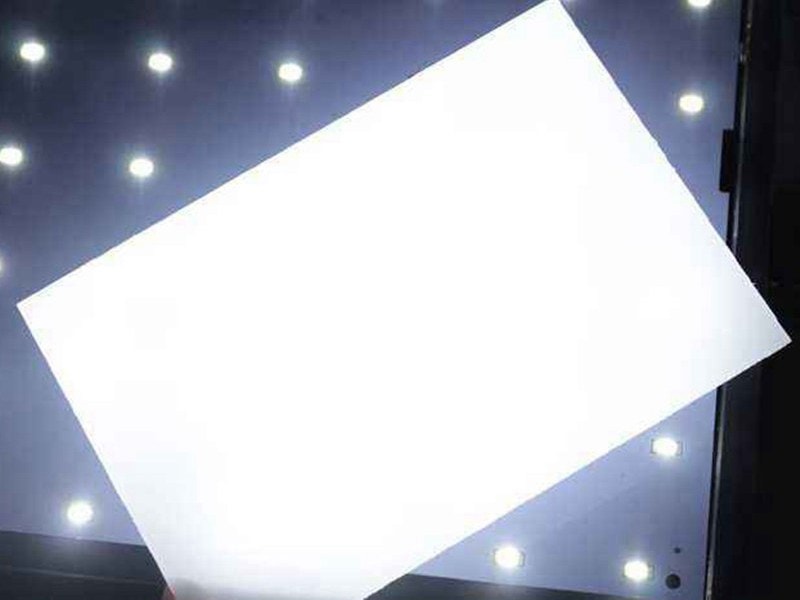

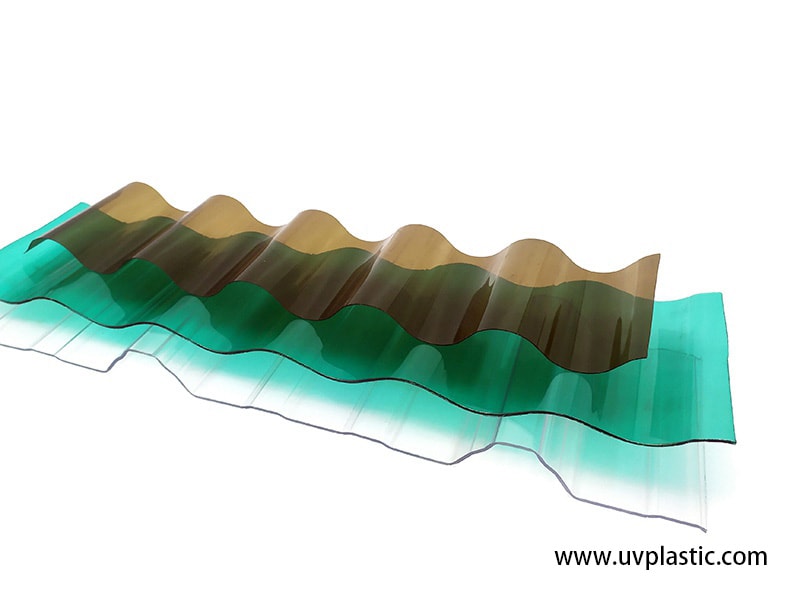

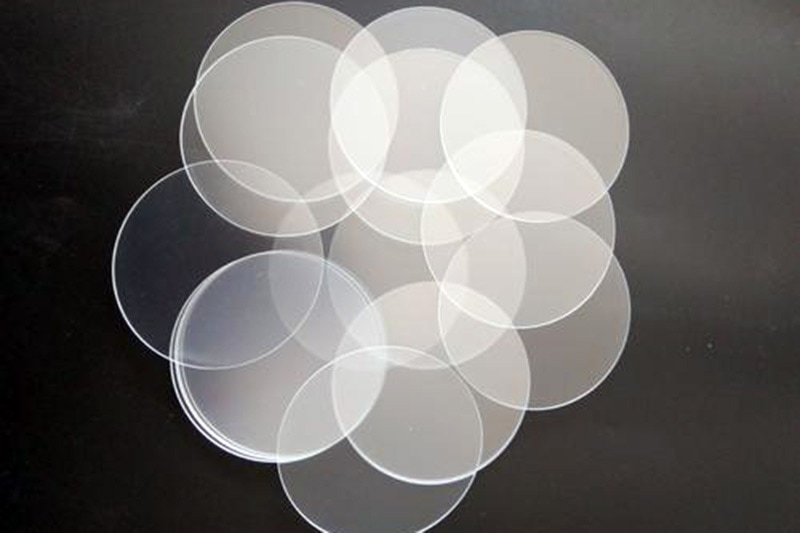

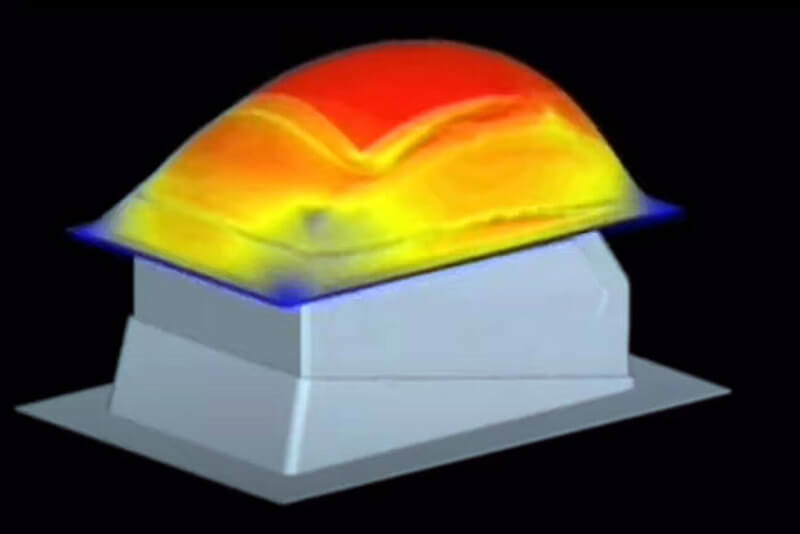

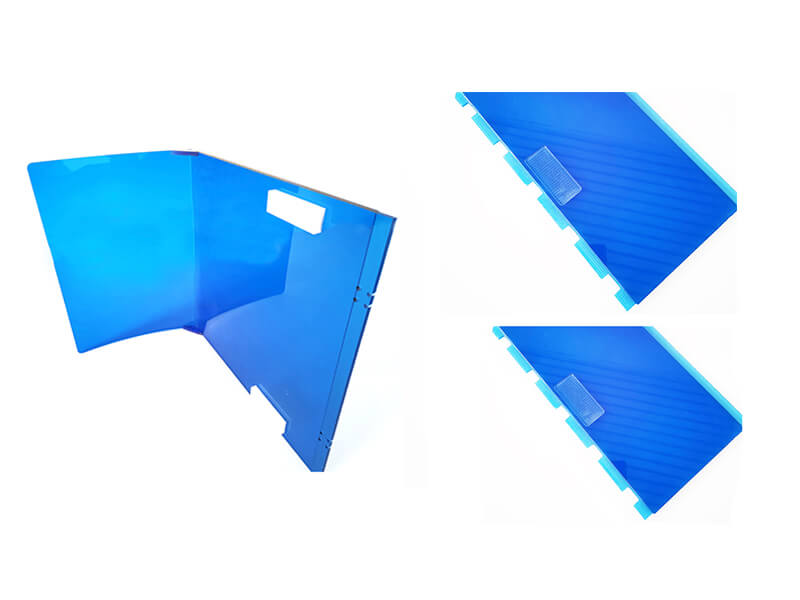

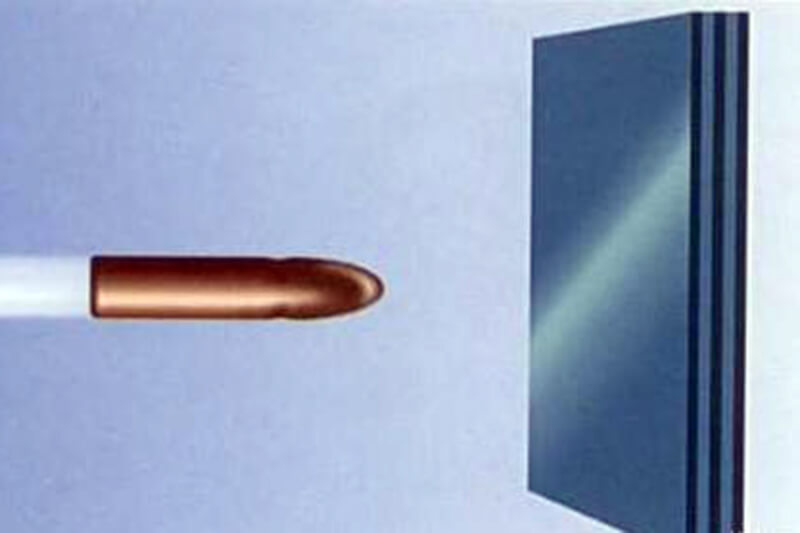

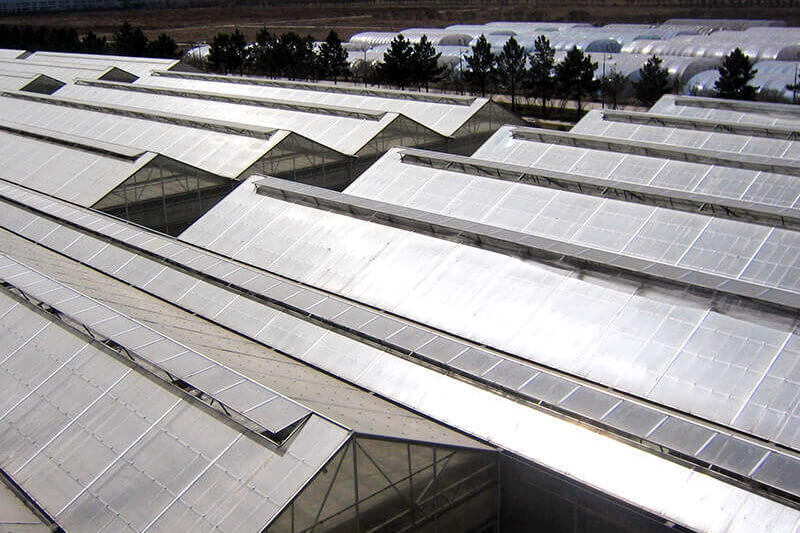

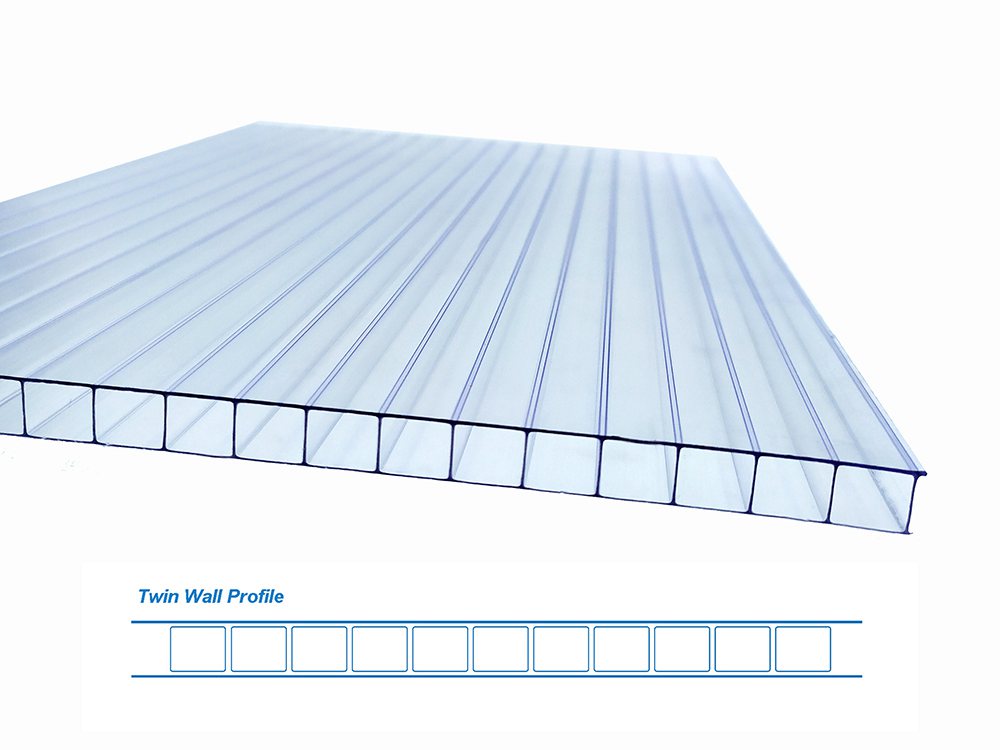

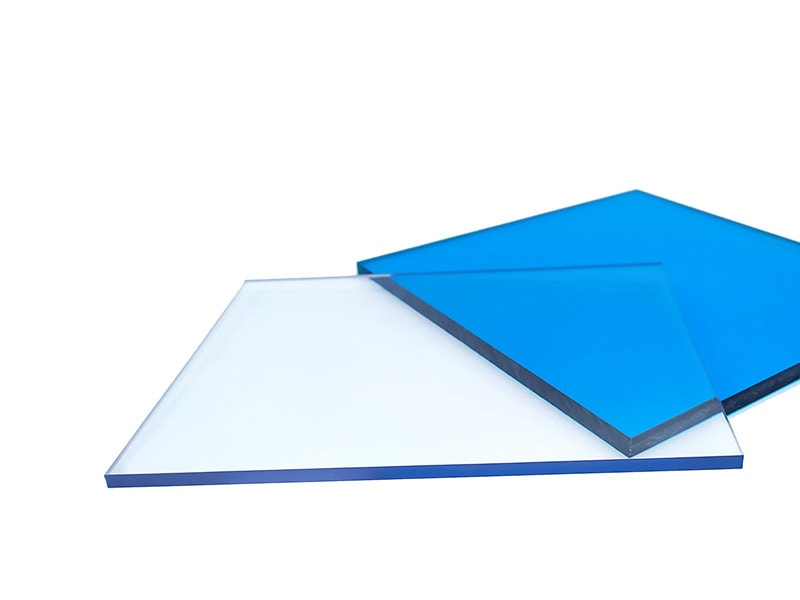

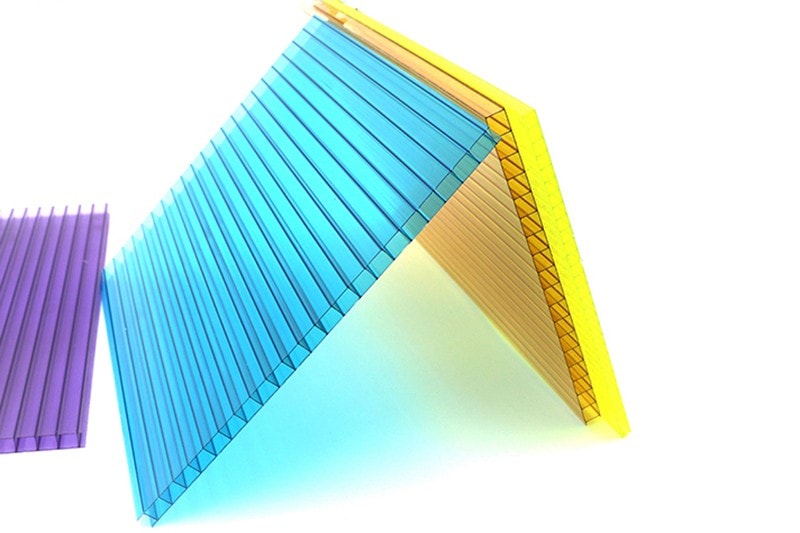

Solid polycarbonate sheet offers high light transmission, excellent impact resistance, and extraordinary durability. It is virtually unbreakable as 250-300 times stronger than glass, 20-30 times stronger than plexiglass sheets, and 25 times stronger than tempered glass. Therefore, it is widely known as polycarbonate glazing sheet, polycarbonate sheet, polycarbonate panel, unbreakable plastic sheet, etc.

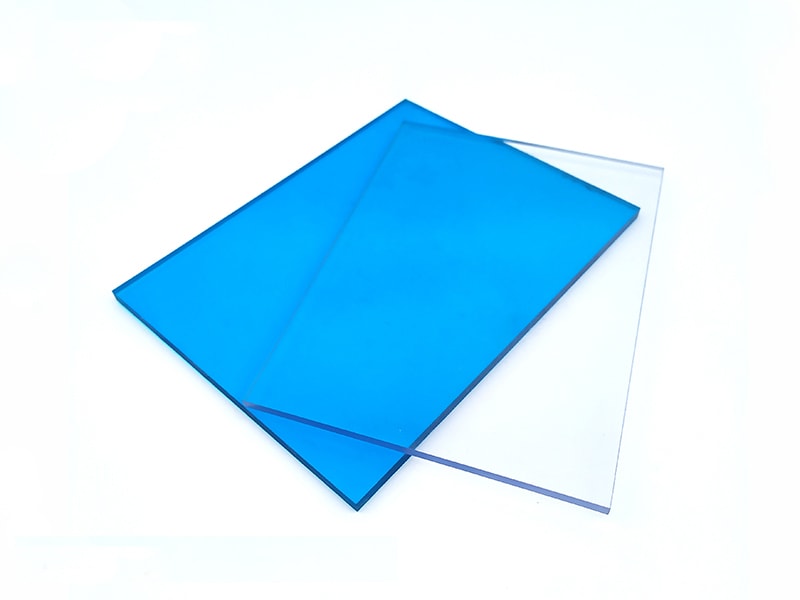

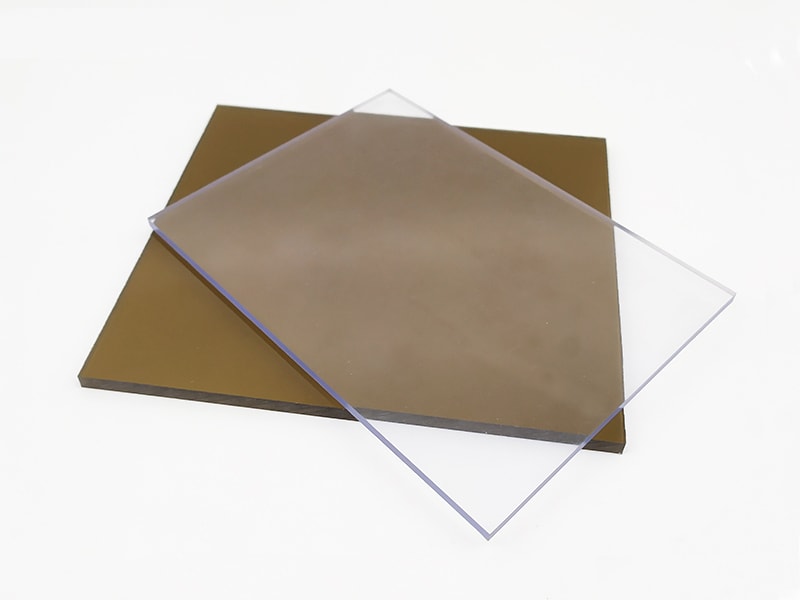

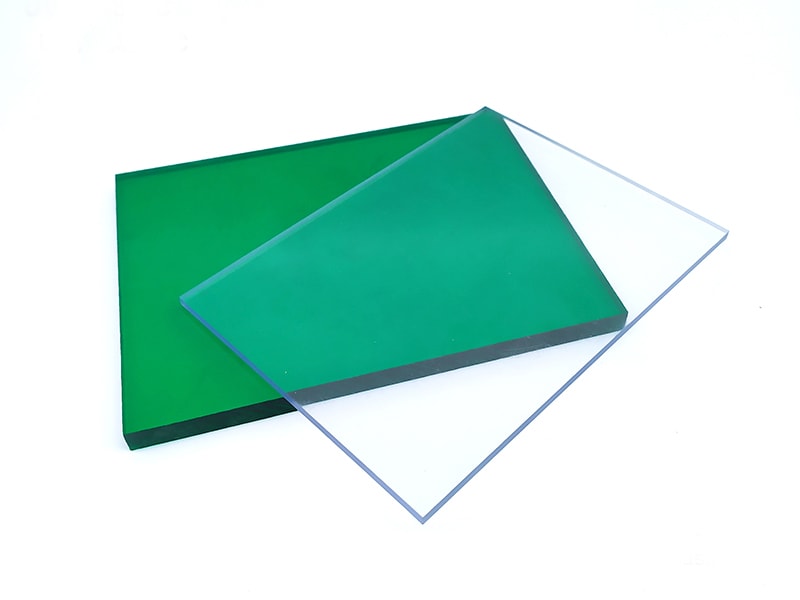

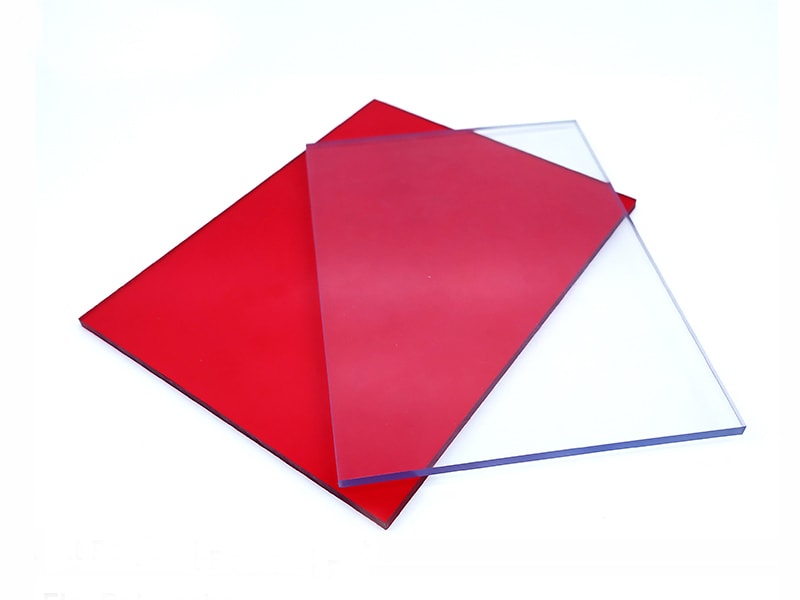

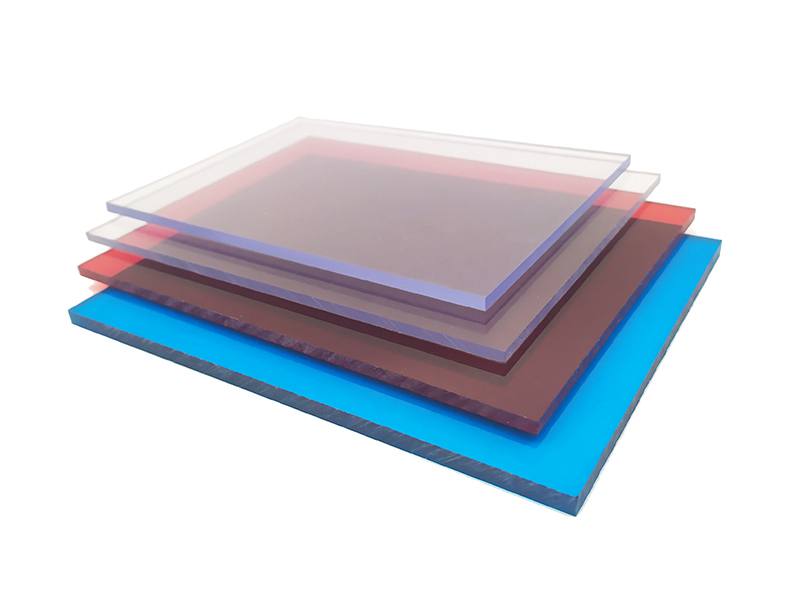

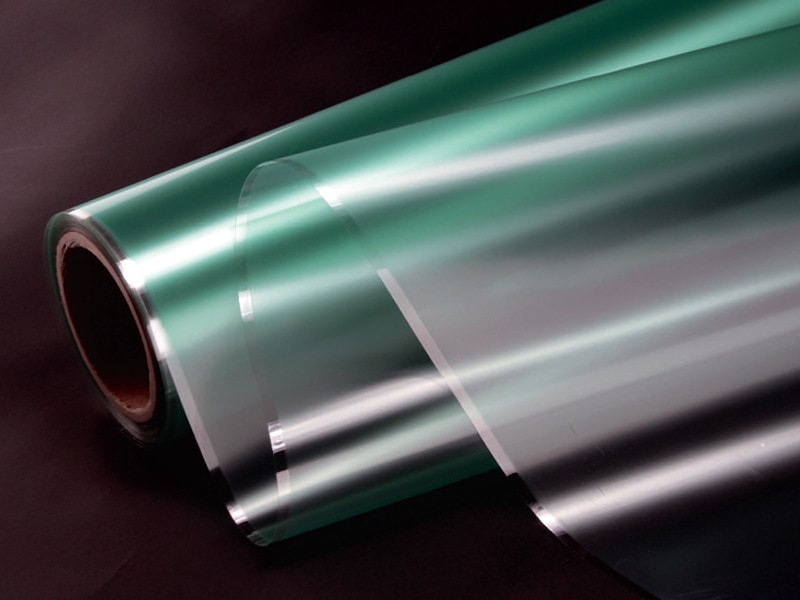

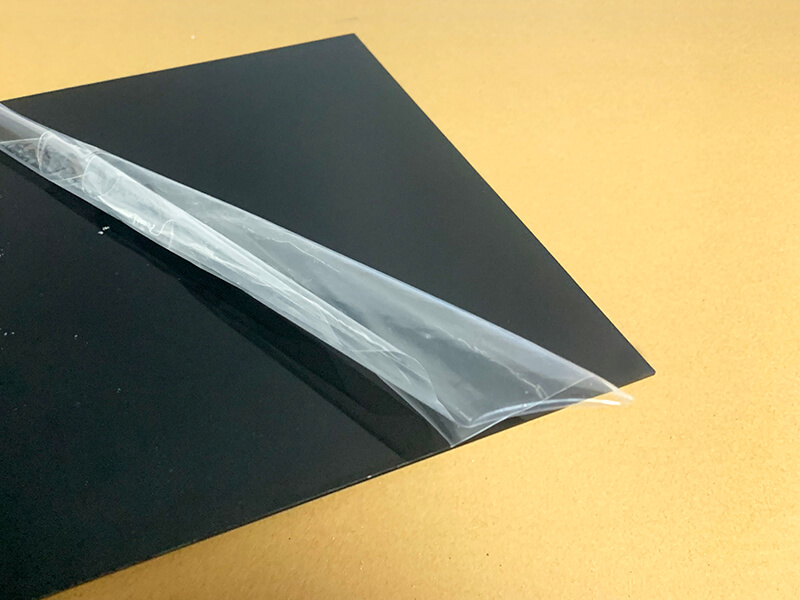

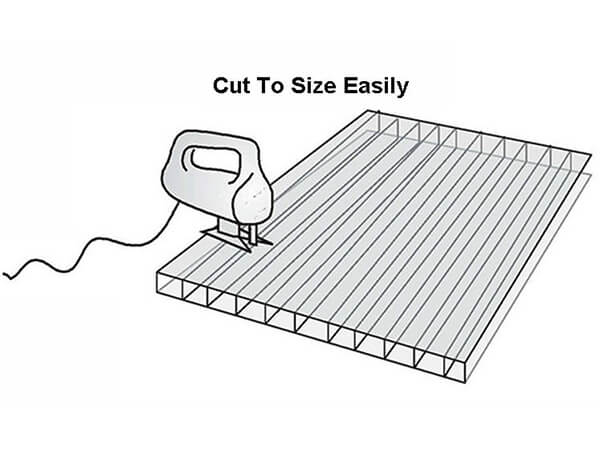

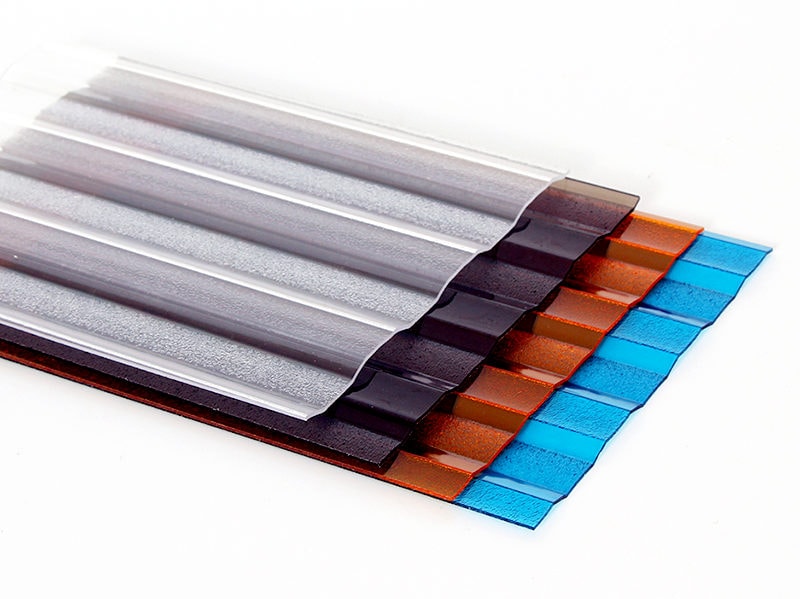

UVFPC-SO is the family code of UVPLASTIC Solid Polycarbonate Sheet. The thickness is from 0.8mm to 100mm, the width is up to 2.65 meters, and the length can be customized. They can be packaged as Rolls or Panels when shipping. Otherwise, UVPLASTIC can cut solid polycarbonate sheets to the sizes according to client’s requirements. The standard colors are clear, blue, green, gray, opal, brown, etc, the custom colors are available subject to MOQ (Minimum Order Quantity). The lifespan is more than 10 years with the UV protective layer.

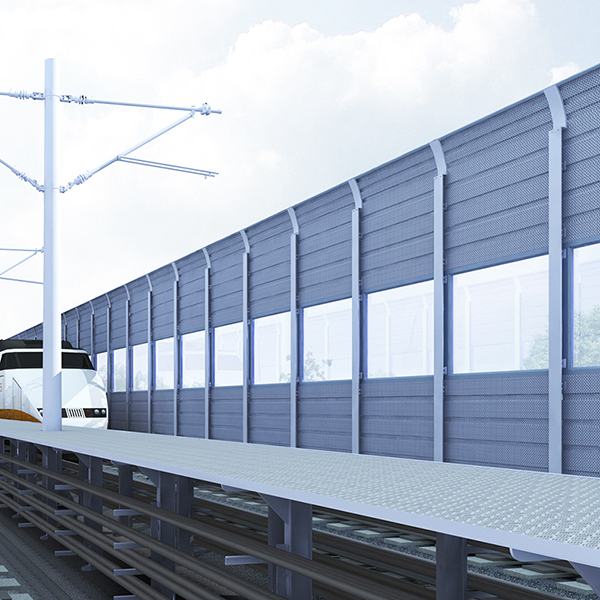

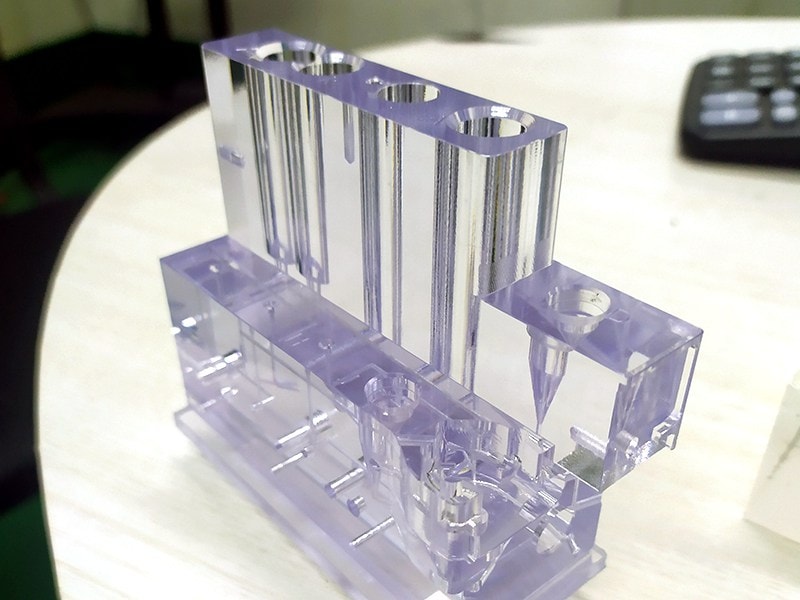

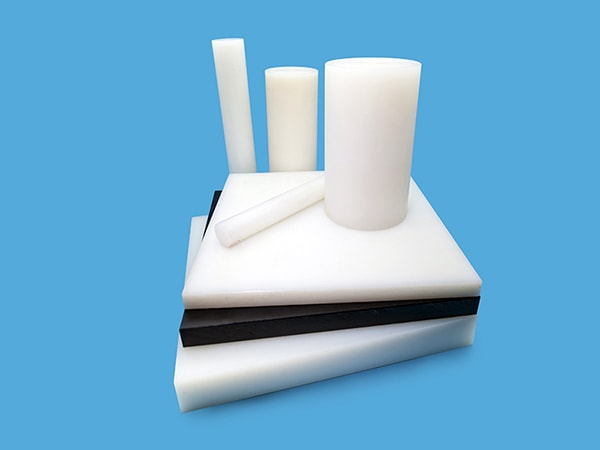

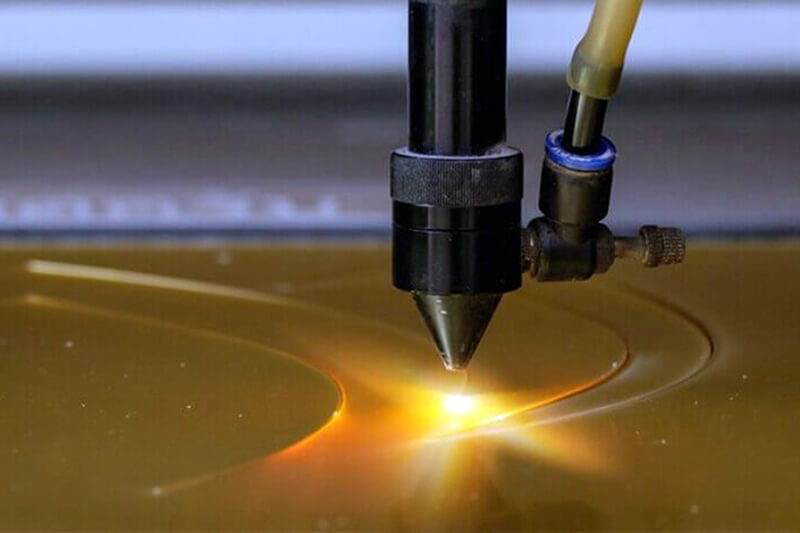

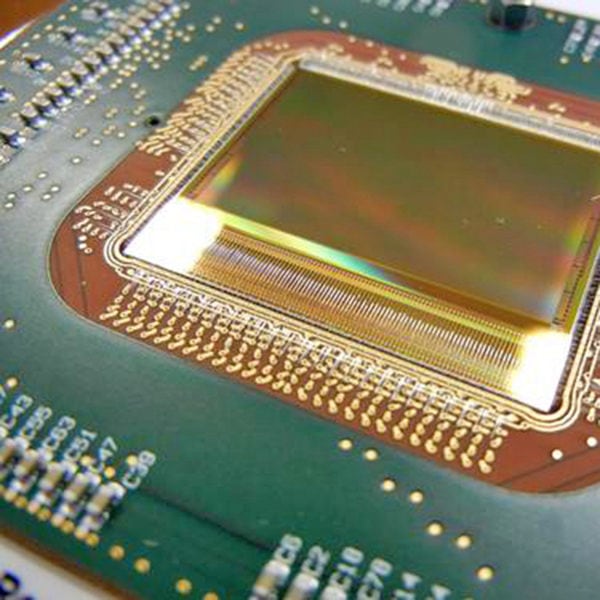

UVPLASTIC™ is the leading manufacturer of polycarbonate sheets in China. All raw material is virgin and environment friendly, which is purchased from Sabic, Bayer, Mitsubishi, and Teijin company. With a strict quality management system, all products offer superior quality. With more than 17 years of experience in the polycarbonate field, UVPLASTIC also provides machining services. Today, we are so honored to provide high-quality Solid Polycarbonate Sheets to more than 2000 clients all over the world, they are in different industries including safety & security, engineering, construction & architecture, decoration, medical & healthcare, transportation, and daily necessities.

UVPLASTIC™ Solid Polycarbonate Specification

Standard size

| Thickness (mm) | Width (mm) | Length (m) |

|---|---|---|

| 0.8mm, 1mm, 1.5mm | 1220mm, 2100mm, 2650mm | 1220mm, 2440mm, 5800mm, 11800mm, 30m (roll), 40m (roll), 50m (roll) |

| 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm | 1220mm, 2100mm, 2650mm | 1220mm, 2440mm, 5800mm, 11800mm |

| 8mm, 10mm, 12mm, 15mm | 1000mm, 1220mm, 2100mm, 2650mm | 1220mm, 2440mm, 5800mm, 11800mm |

| 16mm, 18mm, 20mm | 1000mm, 1220mm, 2100mm | 1220mm, 2440mm, 5800mm |

| 25mm, 30mm, 35mm, 40mm | 610mm, 1050mm, 1220mm | 1220mm, 2440mm |

| 45mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, 200mm, 300mm, 400mm, 500mm | 610mm, 1050mm, 1220mm | 1220mm, 2440mm |

UV Coating Layer

| Model | Description |

|---|---|

| UVFPC-SO | Stabilized UV protective layer for general purpose |

| UVFPC-SO-U1 | The co-extruded UV coating on one side for outdoor application |

| UVFPC-SO-U2 | The co-extruded UV coating on both sides for outdoor application |

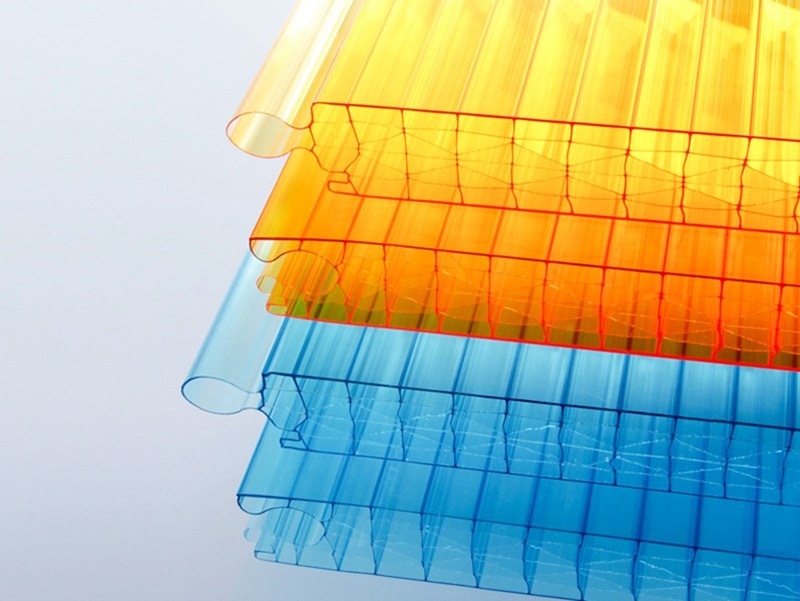

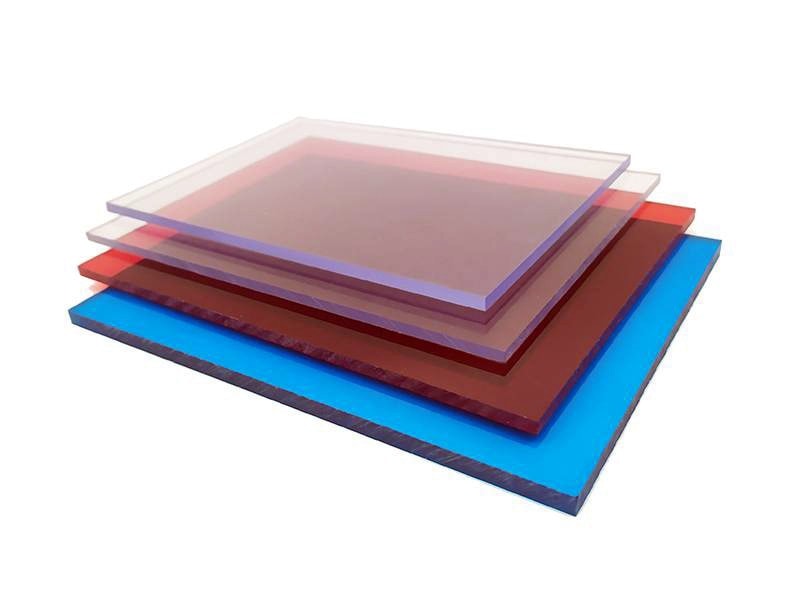

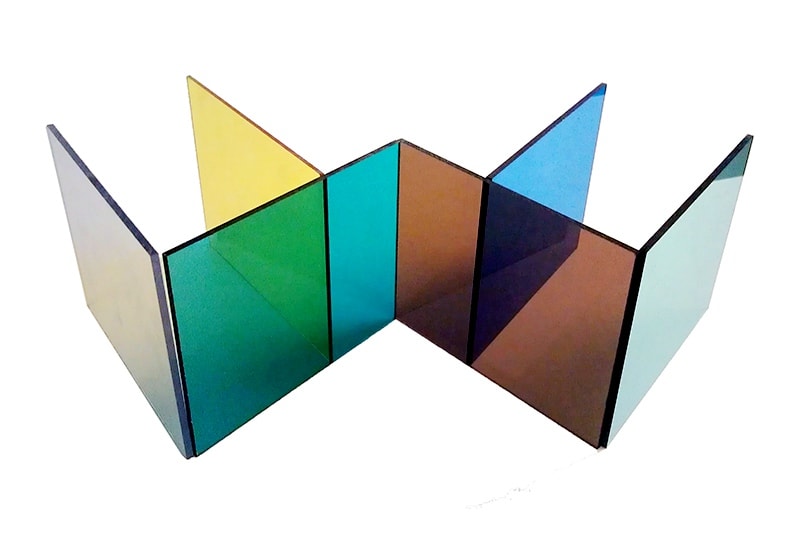

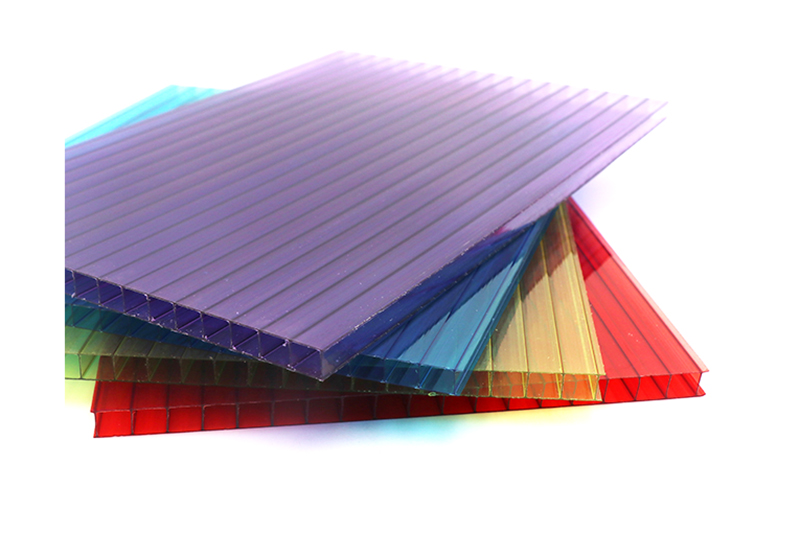

Colors

| Type | Colors description |

|---|---|

| Transparent | Clear, Bronze, Red, Blue, Green, Solar Grey, Lighter Blue, Lighter Green |

| Translucent | White Opal, White Diffuser, Yellow, Red, Mint Green |

| Opaque | Black, Yellow, Dark Blue, Cream, Dark Grey, Dark Brown |

Physical Properties

| Property | Test Method | Testing Condition | Unit | Value |

|---|---|---|---|---|

| Density | D-792 | g/cm3 | 1.2 | |

| Heat Deflection Temperature | D-648 | Load: 1.82 MP | °C | 135 |

| Short Time Service Temperature | °C | from -50 to +130 | ||

| Long Time Service Temperature | °C | from -40 to +100 | ||

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 | |

| Thermal Conductivity | C-177 | W/m K | 0.21 | |

| Tensile Strength at Yield | D-638 | 10 mm/min | Mpa or N/mm² | >65 |

| Tensile Strength at Break | D-638 | 10 mm/min | MPa or N/mm² | >60 |

| Elongation at Yield | D-638 | 10 mm/min. | % | 6 |

| Elongation at Break | D-638 | % | >95 | |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | MPa | 2350 |

| Flexural Strength | D-790 | 1.3 mm/min. | MPa | 100 |

| Flexural Modulus | D-790 | 1.3 mm/min. | MPa | 2600 |

| Impact Falling Weight | ISO 6603/1 E50 | 3mm sheet | J | 158 |

| Light Transmission | D-1003 | % | 82 – 92 | |

| Haze | D-1003 | % | <0.5 | |

| Flammability Rate | UL 94 | V-2 |

- Default third-party testing organization is SGS;

- The fire rating is V2/UL94 for standard solid polycarbonate sheet, want to know V0 fireproof polycarbonate sheet;

Download Catalogs

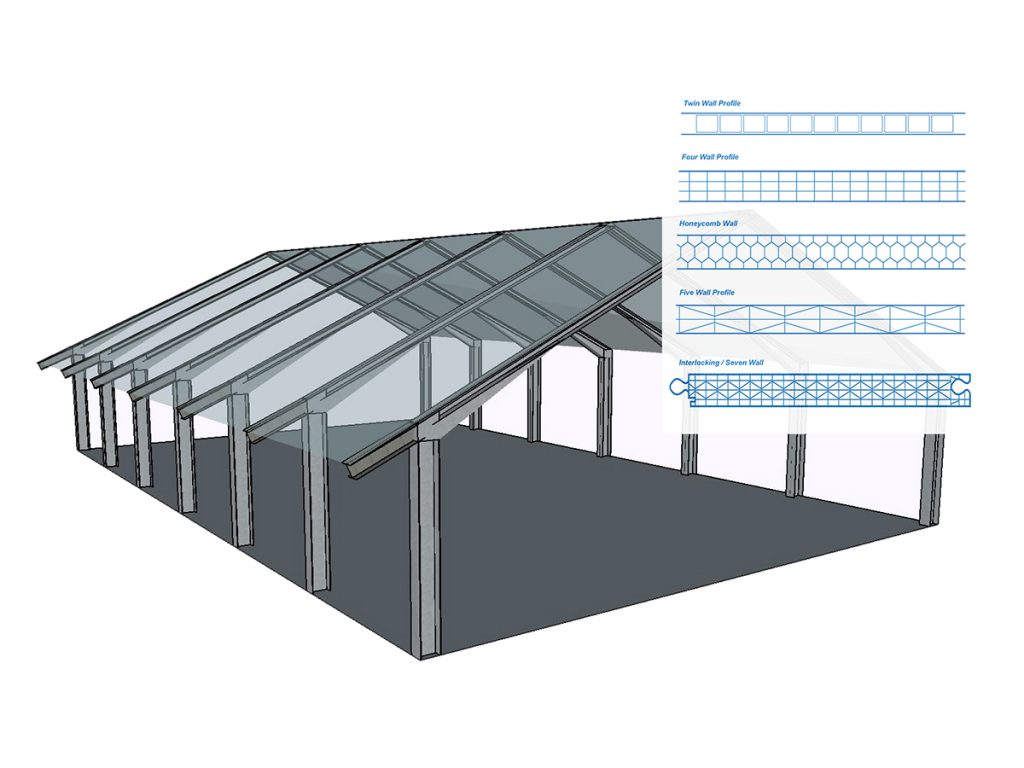

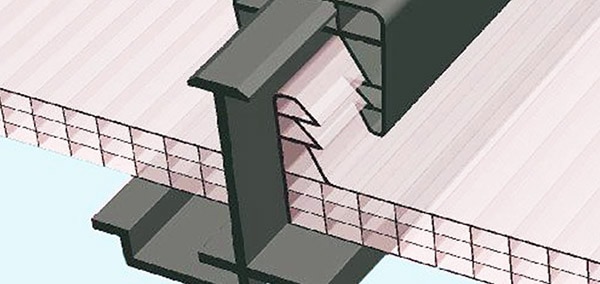

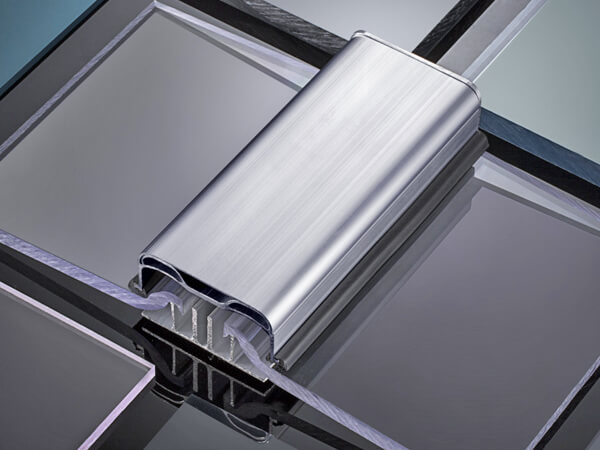

Typical Applications

Related Products

Related Articles

Frequently Asked Questions

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.