LED Light Diffuser Made of Polycarbonate Plastic

Best Light Diffuser Solution by Polycarbonate Plastic

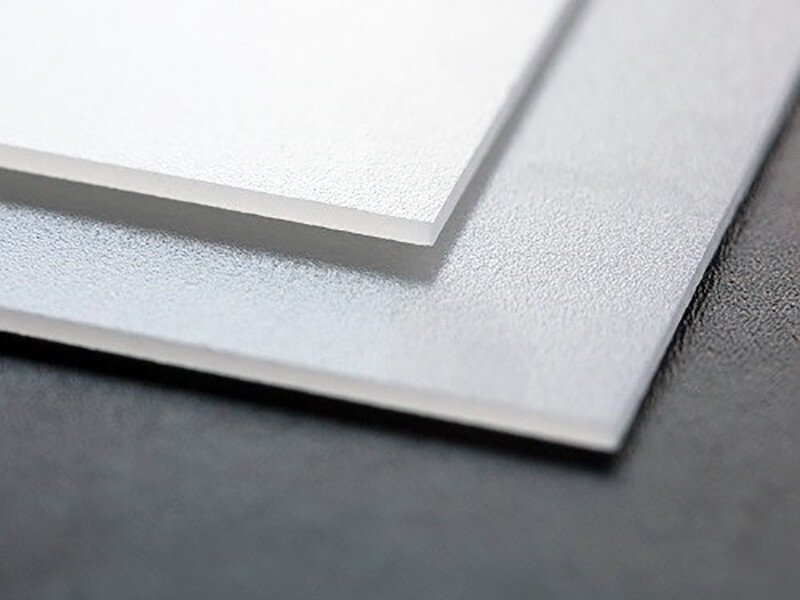

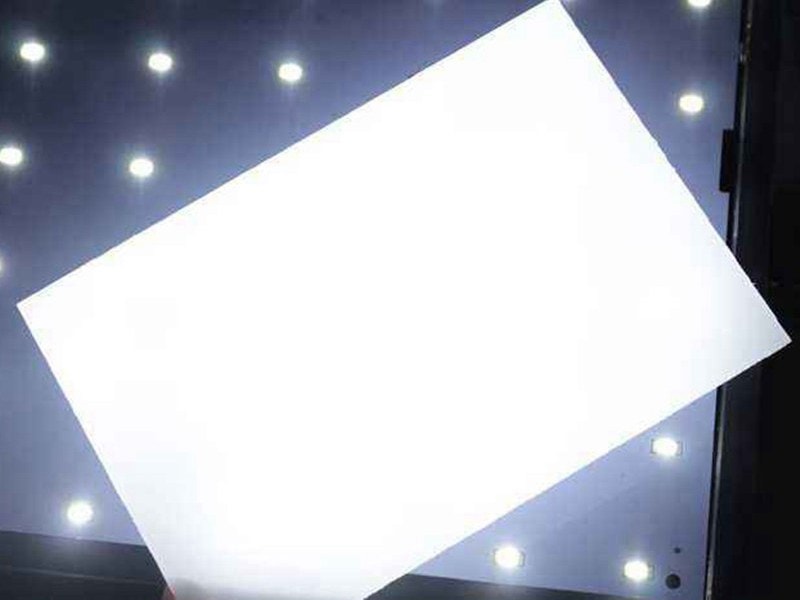

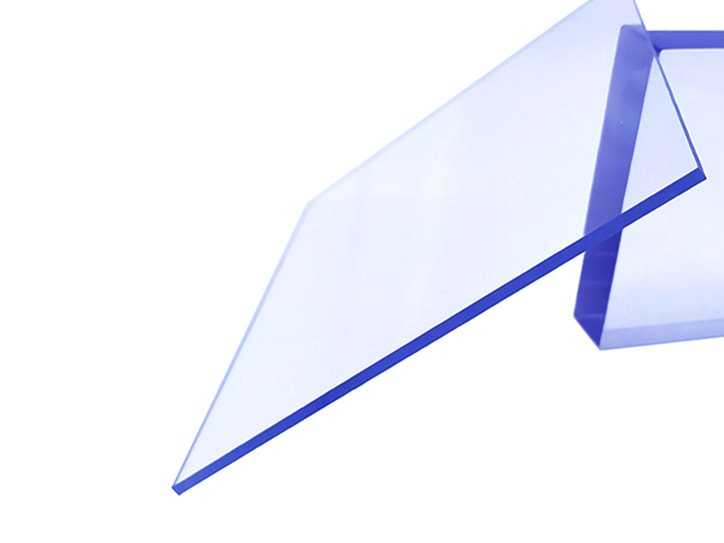

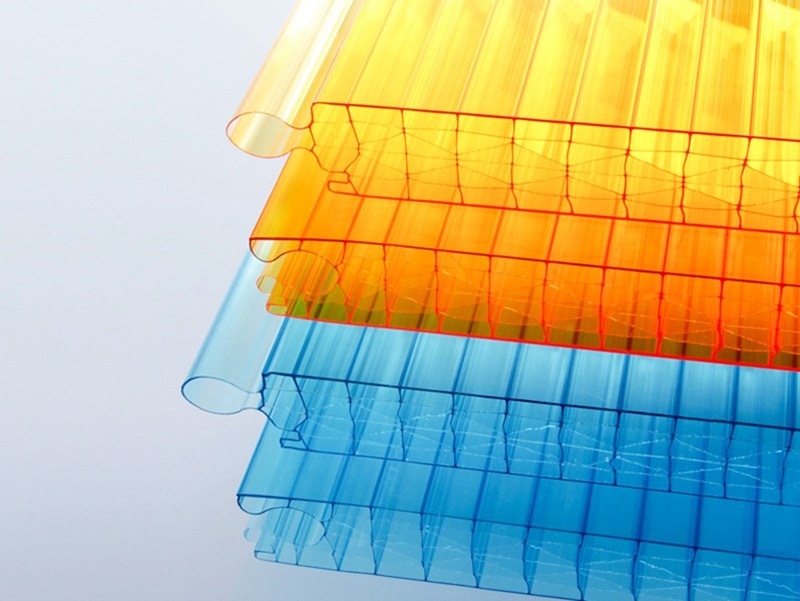

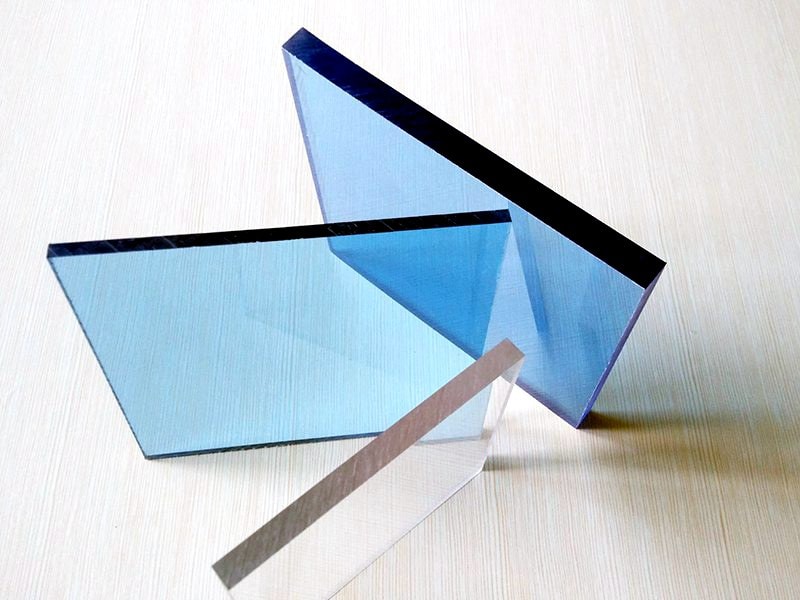

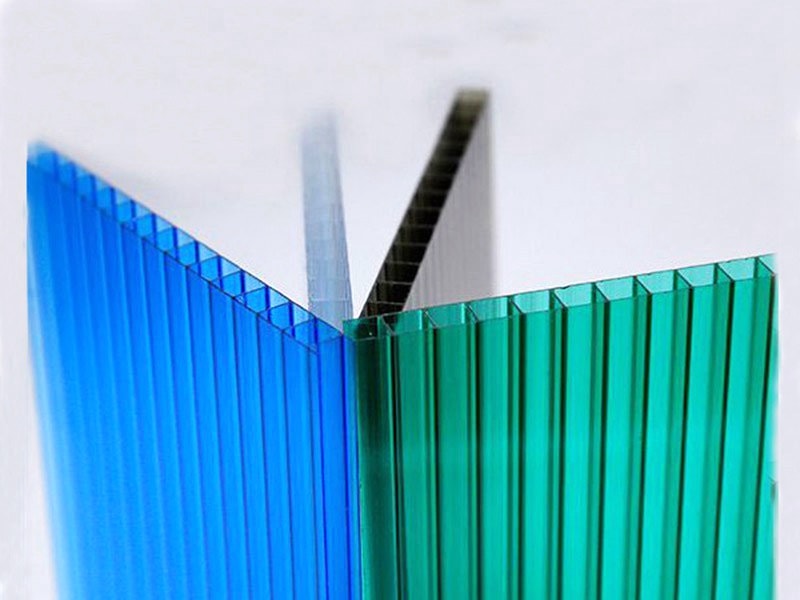

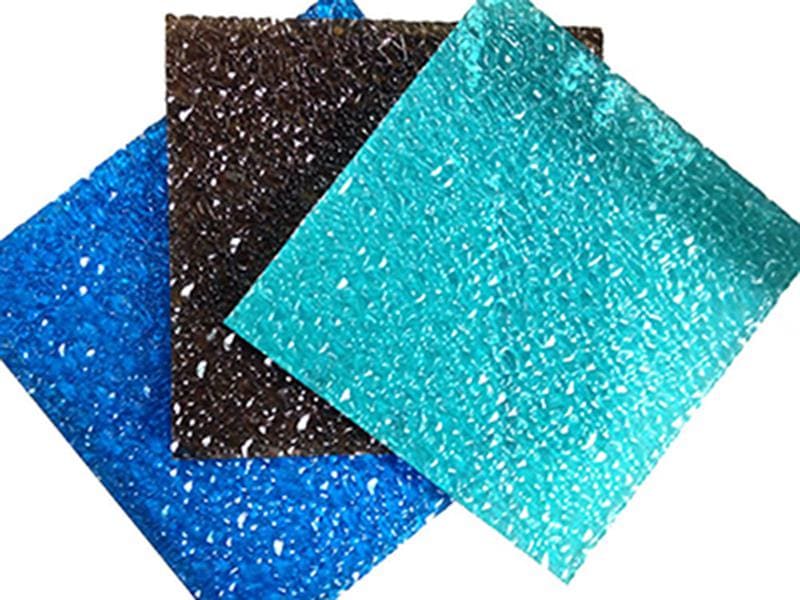

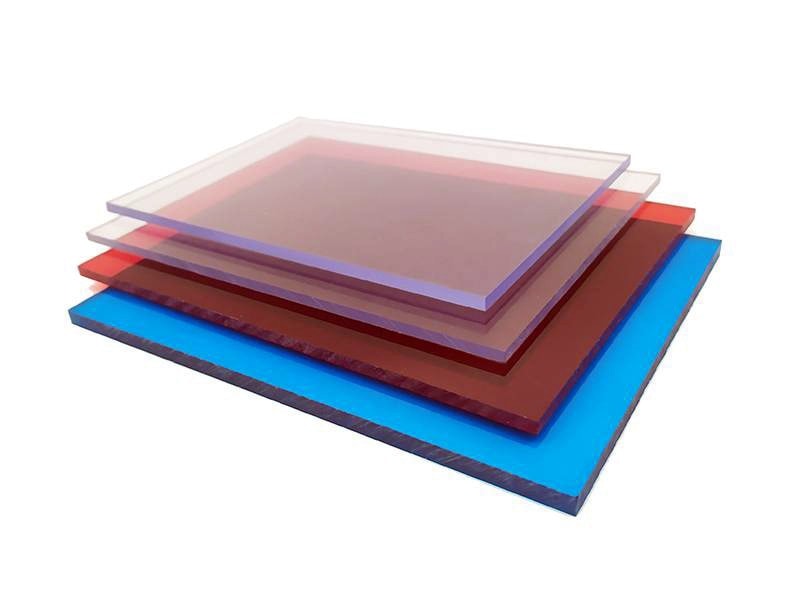

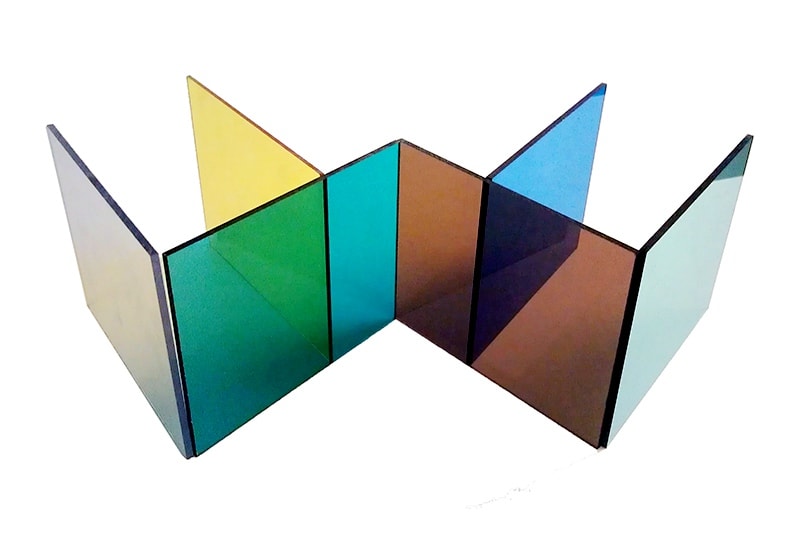

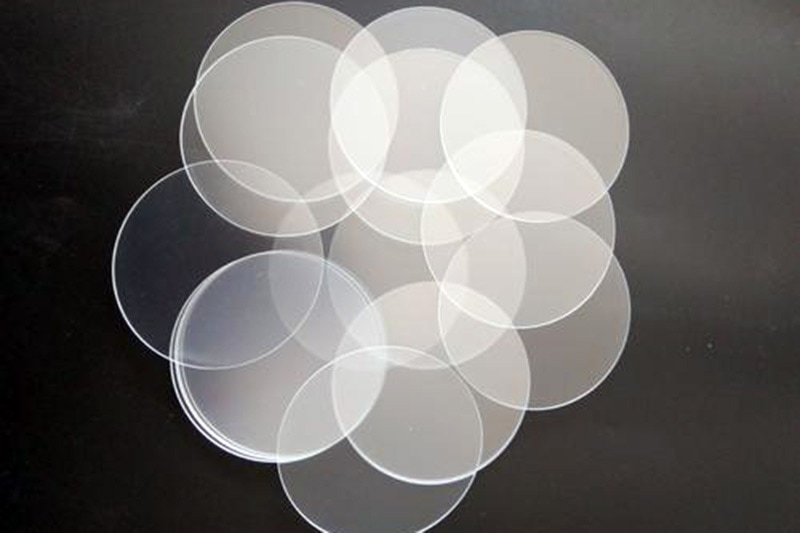

UVPLASTIC™ Light Diffuser and non-glare light diffuser sheets are made of polycarbonate plastic, which is mainly used as the cover protection for downlights, panel lights, advertisement billboards, Mini LED, the light covers of the printed circuit board, office lamps, kitchen lights, and fluorescent lights. It can scatter light spots equably on the surface, then, you can get soft and comfortable light rays. UVPLASTIC™ Polycarbonate Light Diffuser is an efficient and excellent light diffuser material, the thicknesses are from 0.8 mm to 5mm, it is also known as “LED Light Diffuser“, “Polycarbonate Diffuser“.

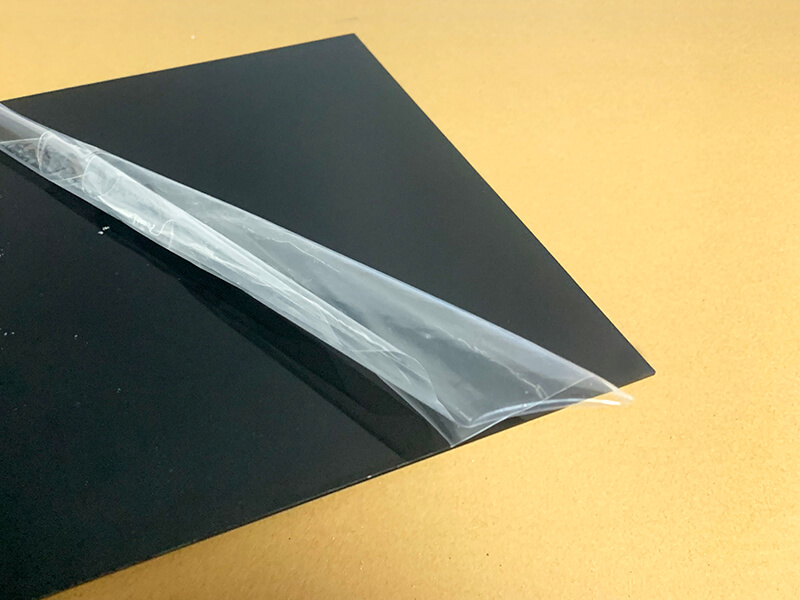

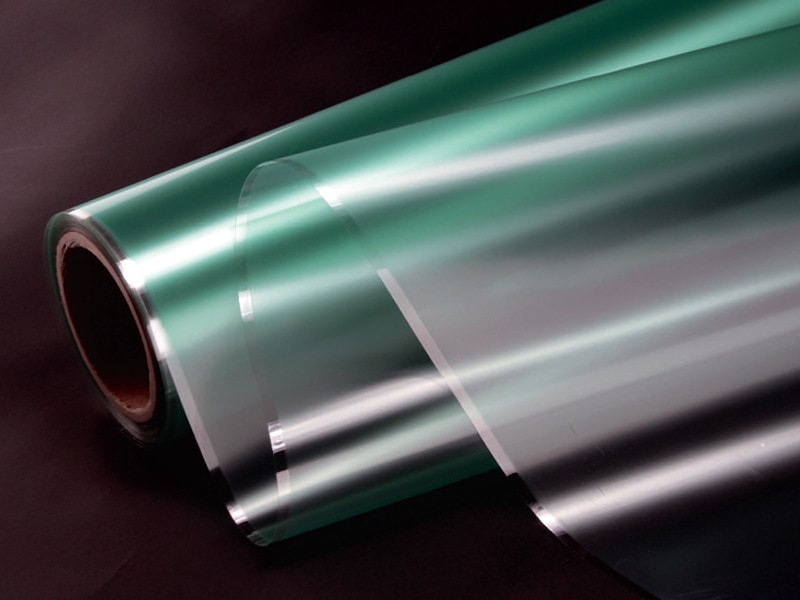

UVPLASTIC provides a high-quality reflection film, which is made of polycarbonate plastic, the thickness ranges from 0.2mm to 0.4mm, which offers great light reflection capability and works well at temperatures between -40 and 120 degrees. Reflection film is also one of the main parts of LED Lights. Otherwise, UVPLASTIC developed diffuser film for displayers, LED screens, mobile phone screens, membrane switches, etc. It is also made of high-quality polycarbonate plastic. The thickness ranges from 0.06mm to 0.8mm.

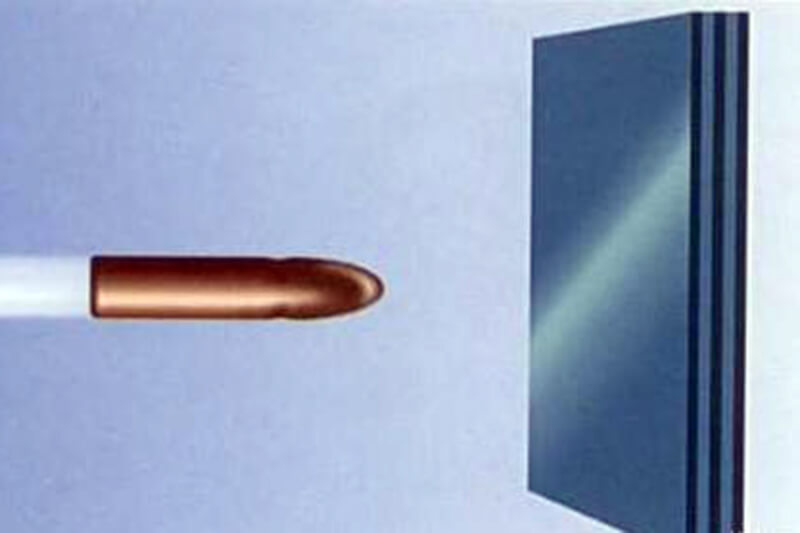

Compared with the PMMA diffuser, the polycarbonate diffuser offers higher impact resistance, better flame retardance, and dimensional stability in a large temperature from -40 °C to 120 °C. Therefore, It is the right material for the LED lamp, LED sign, architectural lighting system, elevator lighting system, railcar lighting system, etc. Otherwise, Polycarbonate Diffuser Sheet/Film is also the right choice for industrial applications including electron industry, machine vision system, and medical device inspection.

With more than 15 years of experience in manufacturing polycarbonate diffusers, UVPLASTIC has grown to be a leading manufacturer of Light Diffuser Sheet in China and provides light diffusers with custom size, machining service, and OEM service for more than 1200 clients from more than 40 countries.

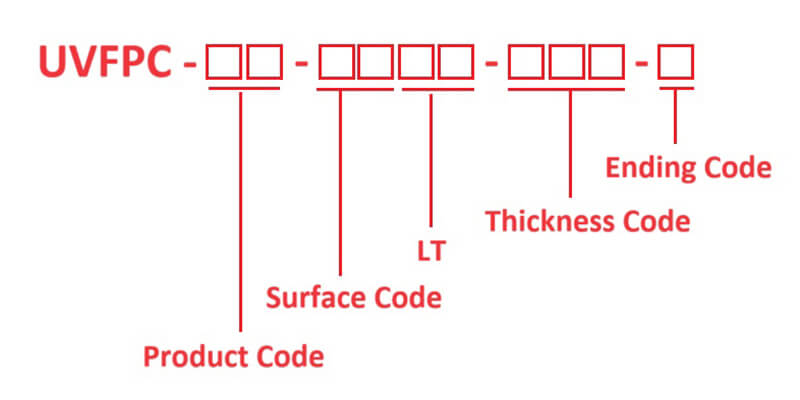

UVPLASTIC™ Light Diffuser Specification

Product Range

| Model | Product Name | Standard Thickness | Luminousness or Reflection (%) | Remark |

|---|---|---|---|---|

| UVFPC-DI | Light Diffuser Sheet | 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 3mm, 4mm, 5mm | From 60% to 85% | For Indoor Use Only, Packaged as Roll or Panel |

| UVFPC-DIU | Light Diffuser Sheet | 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 3mm | From 75% to 85% | For Indoor or Outdoor Use, Packaged as Panels |

| UVFPC-TDI | Light Diffuser Film | 0.06mm, 0.08mm, 0.1mm, 0.125, 0.15, 0.2mm, 0.25mm, 0.3mm, 0.4mm | From 80% to 90% | Packaged as Roll |

| UVFPC-RF | Light Reflector | 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.4mm | From 94% to 97% | |

| UVFPC-NG | Non-glare Diffuser Panel | 0.5mm, 0.8mm, 1mm | 95% | |

| UVFPC-CU | Custom diffuser profile/part | Custom |

Model of Polycarbonate Diffuser

Polished Surface and Frosted Surface

| Product Code | Thickness (mm) | Luminousness (%) | Haze (%) | Surface Type | Standard Size (mm) |

|---|---|---|---|---|---|

| DI-0360-500 | 0.5mm | 60±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

| DI-0380-1000 | 1mm | 80±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

| DI-0380-1200 | 1.2mm | 80±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

| DI-0380-1500 | 1.5mm | 80±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

| DI-0380-2000 | 2mm | 80±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

| DI-0380-3000 | 3mm | 80±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

| DI-0380-4000 | 4mm | 80±2% | 95±2% | Polished/Frosted | 1220×2440 mm |

Matte Surface and Frosted Surface

| Product Code | Thickness (mm) | Luminousness (%) | Haze (%) | Surface Type | Standard Size (mm) |

|---|---|---|---|---|---|

| DI-2360-500 | 0.5mm | 60±2% | 95±2% | Matte/Frosted | 1180×1180 mm |

| DI-2370-800 | 0.8mm | 70±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2380-1000 | 1mm | 80±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2380-1200 | 1.2mm | 80±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2380-1500 | 1.5mm | 80±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2380-2000 | 2mm | 80±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2380-3000 | 3mm | 80±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-1380-5000 | 5mm | 80±2% | 95±2% | Fine Matte/Frosted | 1220×2440 mm |

High Luminousness (Matte Surface and Frosted Surface)

| Product Code | Thickness (mm) | Luminousness (%) | Haze (%) | Surface Type | Standard Size (mm) |

|---|---|---|---|---|---|

| DI-2385-800 | 0.8mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2385-1000 | 1mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2385-1200 | 1.2mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DI-2385-1500 | 1.5mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

Matte Surface and Frosted Surface

| Product Code | Thickness (mm) | Luminousness (%) | Haze (%) | Surface Type | Standard Size (mm) |

|---|---|---|---|---|---|

| DIU-2375-500 | 0.5mm | 75±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DIU-2385-800 | 0.8mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DIU-2385-1000 | 1mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DIU-2385-1200 | 1.2mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DIU-2385-1500 | 1.5mm | 85±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DIU-2375-2000 | 2mm | 75±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| DIU-2375-3000 | 3mm | 75±2% | 95±2% | Matte/Frosted | 1220×2440 mm |

| Product Code | Thickness (mm) | Luminousness (%) | Haze (%) | Surface Type | Standard Width (mm) | Length (m) |

|---|---|---|---|---|---|---|

| TDI-0190-060 | 0.06mm | 90±2% | 95±2% | Polished/Matte | 1220 | 1000 |

| TDI-0190-125 | 0.125 | 90±2% | 95±2% | Polished/Matte | 1220 | 600 |

| TDI-0190-200 | 0.2mm | 90±2% | 95±2% | Polished/Frosted | 1220 | 600 |

| TDI-0190-300 | 0.3mm | 80±2% | 95±2% | Polished/Frosted | 1220 | 400 |

| TDI-0190-400 | 0.4mm | 80±2% | 95±2% | Polished/Frosted | 1220 | 300 |

| Product Code | Thickness (mm) | Reflection (%) | Surface Type | Standard Size (mm) |

|---|---|---|---|---|

| RF-1294-200 | 0.2mm | 94% | Fine Matt/Matt | 1220×2400 mm |

| RF-1294-250 | 0.25mm | 94% | Fine Matt/Matt | 1220×2400 mm |

| RF-1294-300 | 0.3mm | 94% | Fine Matt/Matt | 1220×2400 mm |

| RF-1294-350 | 0.35mm | 94% | Fine Matt/Matt | 1220×2400 mm |

| RF-1294-400 | 0.4mm | 94% | Fine Matt/Matt | 1220×2400 mm |

| Product Code | Thickness (mm) | Light Transmittance (%) | Haze (%) | Surface Type | Standard Size (mm) |

|---|---|---|---|---|---|

| NG-2390-500 | 0.5mm | 95±2% | 70±2% | Special Frosted Surface | 1180×1180 mm |

| RF-1294-800 | 0.8mm | 95±2% | 70±2% | Special Frosted Surface | 1220×2400 mm |

| RF-1294-800V | 0.8mm | 95±2% | 70±2% | Special Frosted Surface | 1220×2400 mm |

| RF-1294-1000 | 1mm | 95±2% | 70±2% | Special Frosted Surface | 1220×2400 mm |

| RF-1294-1000V | 1mm | 95±2% | 70±2% | Special Frosted Surface | 1220×2400 mm |

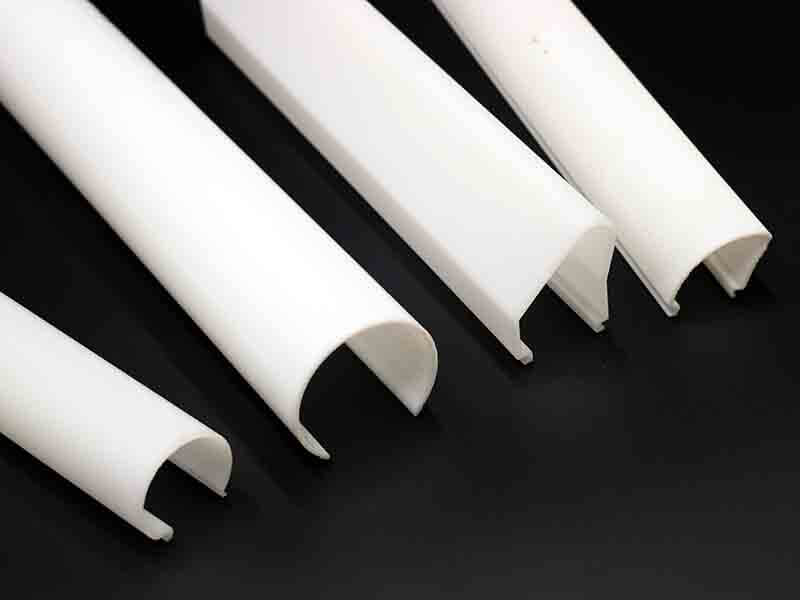

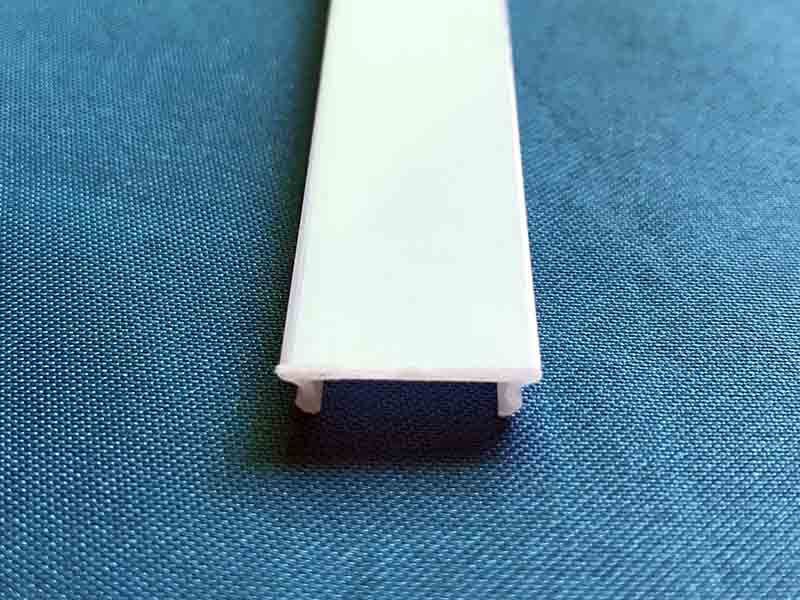

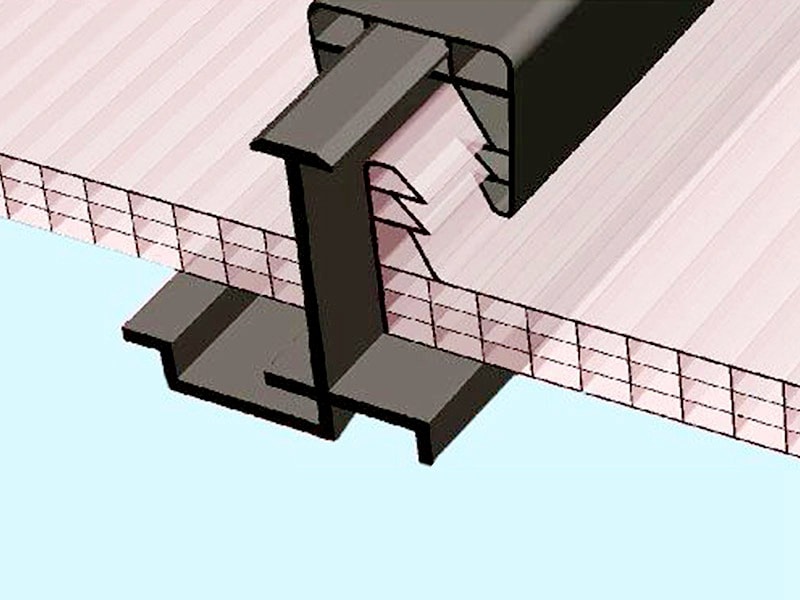

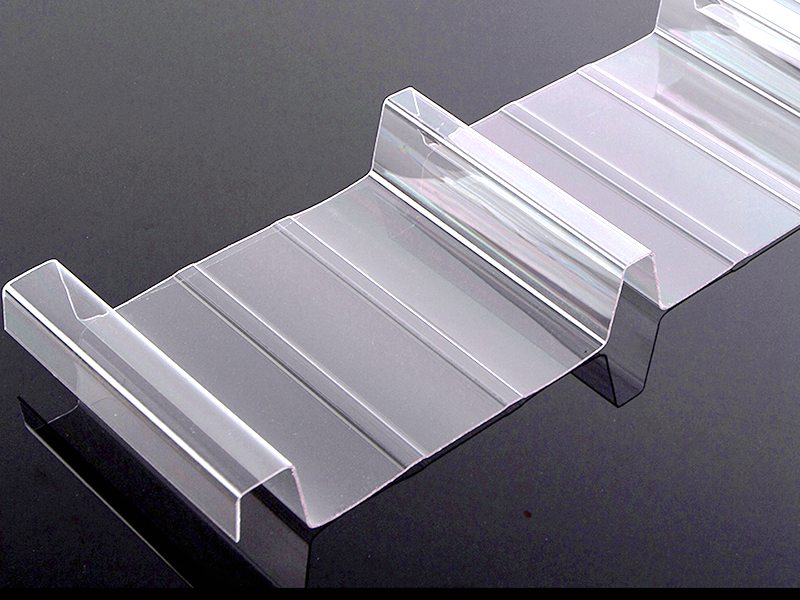

Custom Profile by polycarbonate plastic

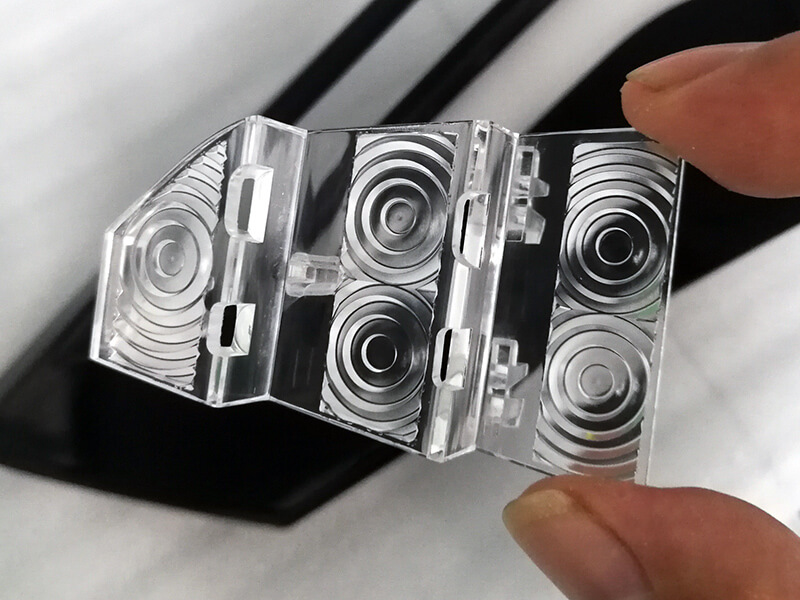

UVPLASTIC provides custom profiles through the extrusion process and injection molding process, the material is polycarbonate plastic with diffuser properties. It offers high luminous transmission, high HAZE, excellent weatherability, and UV resistance. The flame retardance is up to V0/UL94.

Custom Polycarbonate Profile/component offers high resistance, high impact resistance, improved heat aging properties, and superior high luminous transmission. Therefore, it is used in health care equipment, medical devices, recreation equipment, etc.

UVPLASTIC is a leading supplier of custom diffuser profiles in China. Using diffuser materials from Sabic and Covestro, UVPLASTIC provides high-quality custom diffuser profiles/parts for more than 2000 clients in the global market.

Physical Properties

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Water Absorbing Capacity | 0.3 | % | ASTM D570 |

| Elongation at Break | D-638 | % | >100 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Deflection Temperature (264 psi load) | ASTM D648 | °F/°C | 275/135 |

| Vicat Softening Point | ASTM D1525 | °F/°C | 284/140 |

| Maximum Continuous Service Temperature | — | °F/°C | 190/87 |

| Maximum Discontinuous Service Temperature | — | °F/°C | 210/98 |

| Flammability | UL94 | / | V-2 |

| Light transmittance | D-1003 | % | 65-85 |

| Haze | D-1003 | % | <0.5 |

Testing Method Notes:

- The default third-party testing organization is SGS;

- Other testing methods are acceptable besides ASTM standards;

Application

Download Catalogs

Main Benefits of Light Diffuser Film

Related Products

Related Articles

Frequently Asked Questions

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.