Best Plastic Injection Molding Service In China

What is plastic injection molding process?

Plastic Injection Moulding is a manufacturing process for plastic components by injecting molten material into a mould or mold, it is a suitable method for manufacturing high-quality plastic parts in high volume quickly. The injection molding process is suitable for many plastic materials, including most commonly thermoplastic and thermosetting polymers, for example, PC, PMMA, ABS, PS, PA6, POM, PE, PEEK, etc, and these plastic parts are used in the auto industry, appliance industry, medical equipment, food packaging, aircraft industry, etc.

The main advantage of plastic injection molding

Injection molding machine

An injection molding machine, also known as an injection press, works with an injection mold for manufacturing plastic components. It consists of two main parts, an injection unit, and a clamping unit. The famous brands are ENGEL, NETSTAL, Battenfeld, Nissei, LG, HTF, etc.

There are three types of injection mold machines:

Plastic Injection molding Process

Plastic injection molding is a very professional machining method for plastic components, therefore, most companies don’t know the detailed process when need to make plastic parts:

Plastic Material for injection molding

UVPLASTIC provides different injection molding plastic materials for different plastic parts:

| Material Name | Applications | Advantage | Disadvantage |

|---|---|---|---|

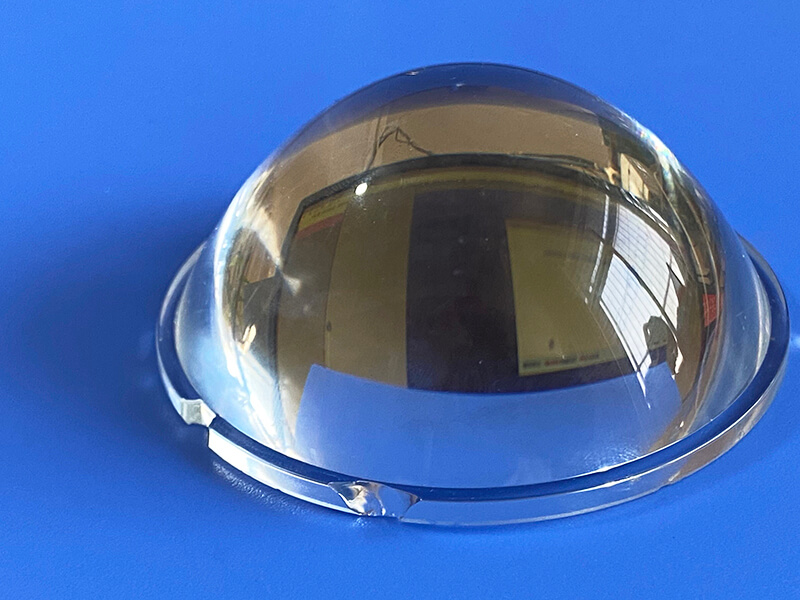

| PMMA or Acrylic (Polymethyl Methacrylate, plexiglass) | Lens, headlight Transparent pipes Light guide part Optical fibers | Outstanding optical properties; Better scratch resistance than polycarbonate; Great polished surface; Easy to polish the surface; A low shrinking percentage; Can be silk-screen printed; Good for thick plastic parts; | Not stronger than PC, and friable material. Heat resistance is not good; |

| Polycarbonate (PC) | Automotive and bus glass; Luggage case; Lights indoor and outdoor; Plastic parts for medical devices; Protection cover for the camera; | Unbeatable strength; Good optical properties; Long lifespan outdoor; Good dimensional stability; High heat resistance; Low shrink; | Poor scratch resistance; Not good for opaque parts, ABS/PC blend material is a good alternative; Not good for thick plastic parts can use PMMA for thick plastic parts. |

| ABS (Acrylonitrile butadiene styrene) | Automotive interior parts; Headlight part; Door handle; Machine housings; | High dimensional stability; Inexpensive cost; Tough, impact-resistant; Good chemical-resistant; Low shrink; | Not good for thick plastic parts; |

| ABS/PC (blend plastic material) | Glove boxes; Overhead and middle consoles; TV frames Laptop monitor enclosures; Knee bolsters; Blow-molded seatbacks; | Combines the strength and heat resistance of PC with the flexibility of ABS; High impact strength and thermal resistance; Price is better than polycarbonate; | / |

| POM or Acetal (Polyoxymethylene) | Automotive Interior Appearance; Plastic parts for Medical and Healthcare; Electrical switch components; Gears, pump impellers; Bearing; | Strength is higher than all polyamide varieties; The yield strength is higher than that of nylon 6 and nylon 610; High strength, toughness, rigidity, and low coefficient of friction in a wide temperature range; Oil resistant and many chemical reagents and solvents; Good wear resistance; | High hygroscopicity; Reduced impact strength in a dry environment; The molding process is difficult to control; |

| PA or Nylon (polyamide) | Plastic machine parts; Wear pads; Wheels; Gloves; Guitar strings; Tennis racket; Strings; Medical implants; Electrical connectors; Gears | High mechanical strength, and stiffness; Good sliding properties; High hardness, and toughness; Good fatigue resistance; High mechanical damping ability; Excellent wear resistance; Good electrical insulating properties; | High shrinkage in molded sections; Pollution problems; Low absorbency; |

| HDPE (High-density polyethylene) | Plastic bottles; Chemical containers; Plastic automobile parts; Storage containers; | High Strength; Good resistance to chemicals, including water, solvents, acids, and detergents; Better price; | Highly Flammable; High Thermal Expansion; Not Resistant to Chlorinated Hydrocarbons; |

| PEEK (Polyether Ether Ketone) | Plastic parts for aerospace; Plastic parts for medical and healthcare; Seals, Washers, and Bearings for Automotive parts; Electrical/electronic parts; | Exceptional tensile properties; Excellent creep resistance; Low friction; Good dimensional stability; Exception insulation properties; Excellent sterilization resistance at high temperature; | Expensive; Processing at high temperatures; Low resistance to UV light; |

Low-volume manufacturing by injection molding

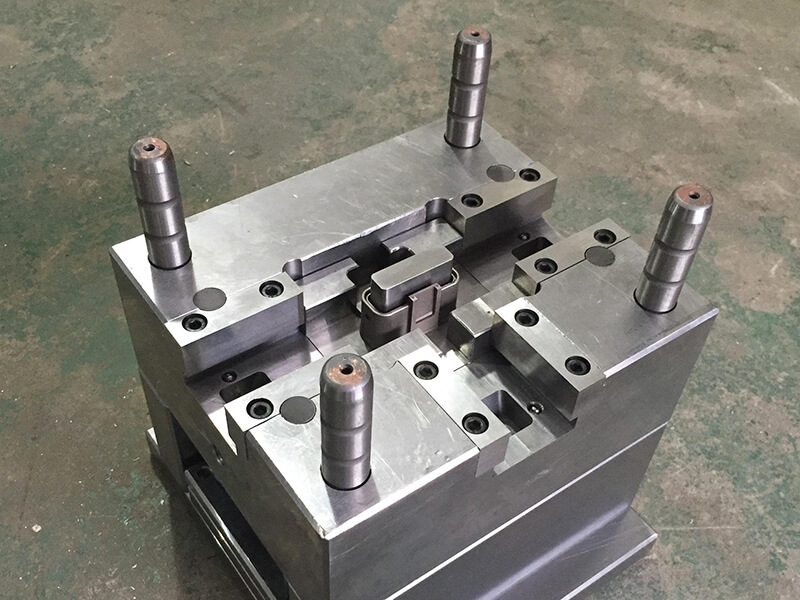

Normally, injection molding is good for high-volume products, but we can make soft tooling for injection molding, which is suitable for low-volume plastic parts.

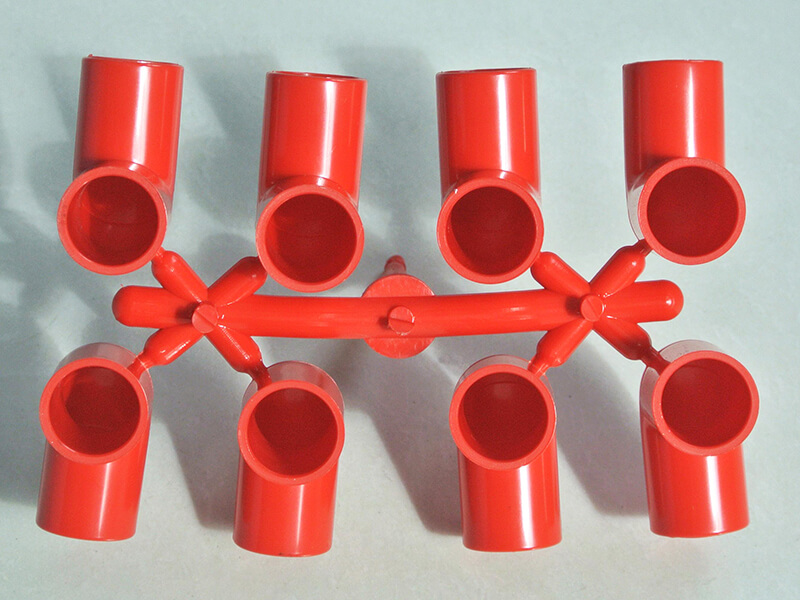

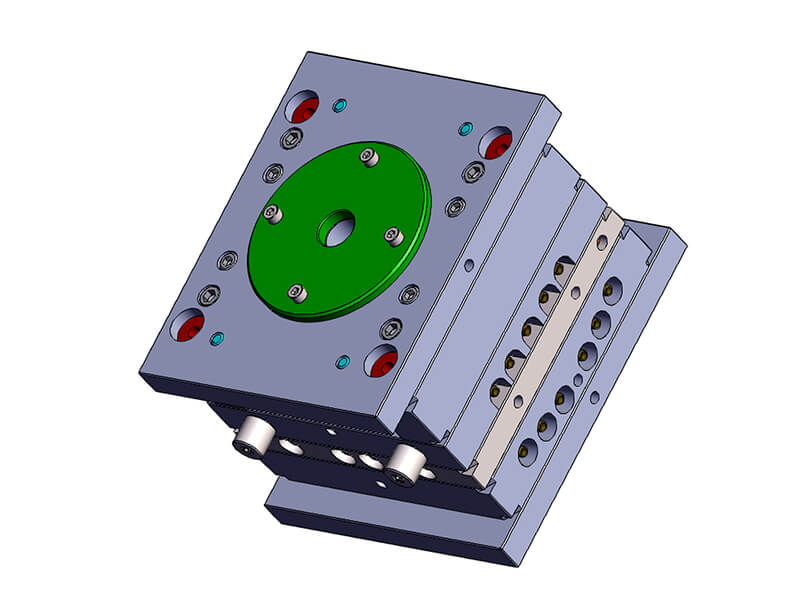

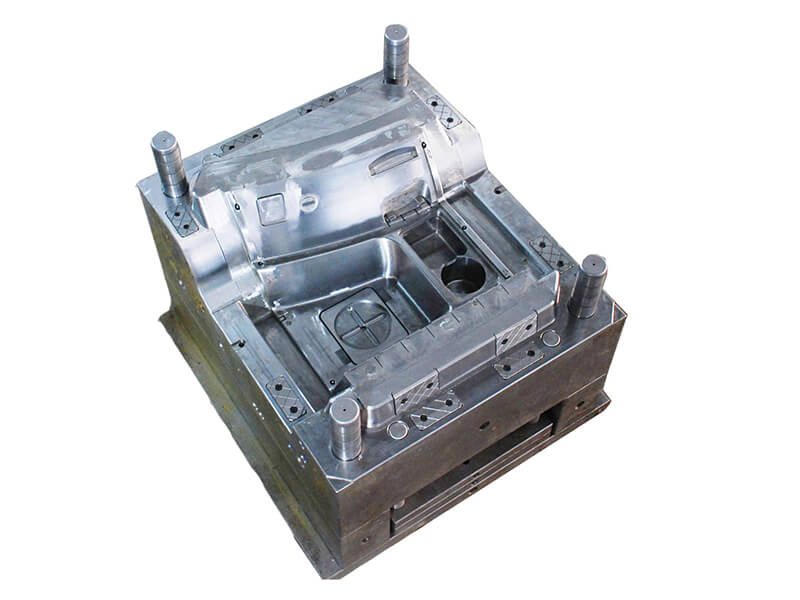

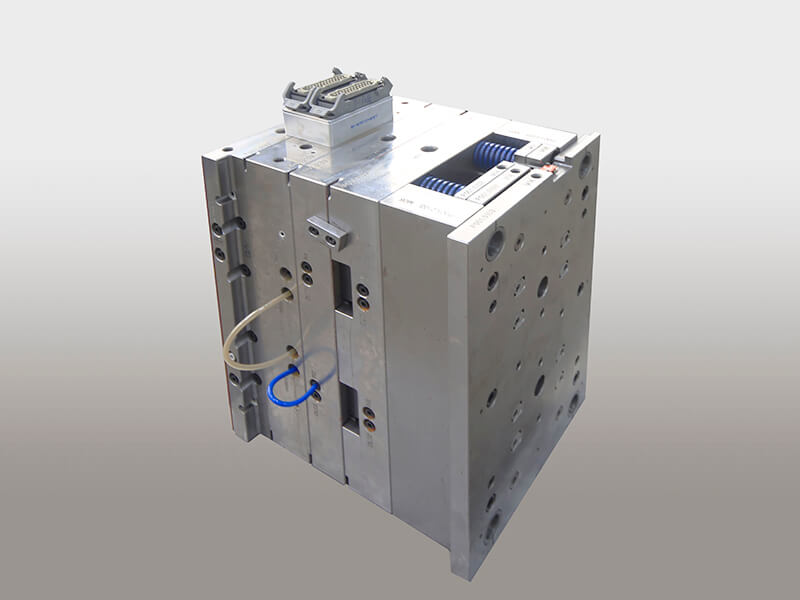

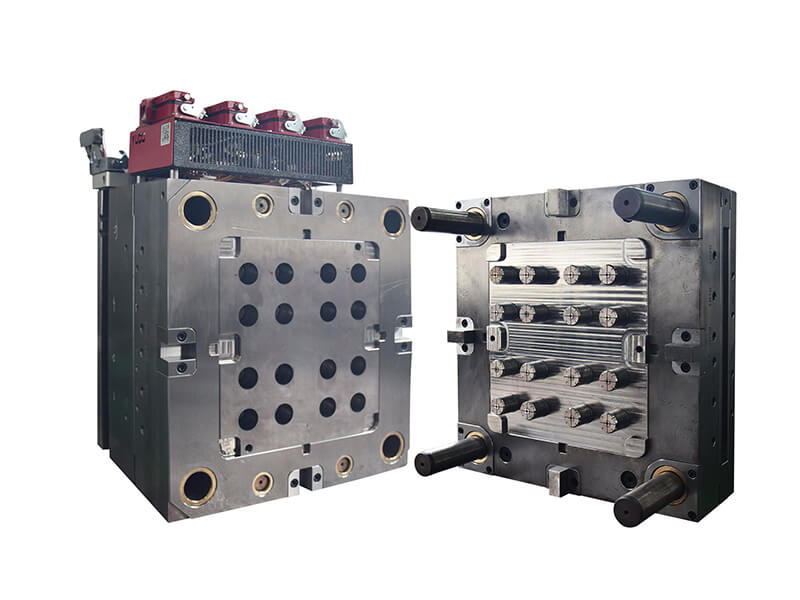

Gallery of injection parts

Frequently Asked Questions

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.