Leading Manufacturer of Polycarbonate Films in China

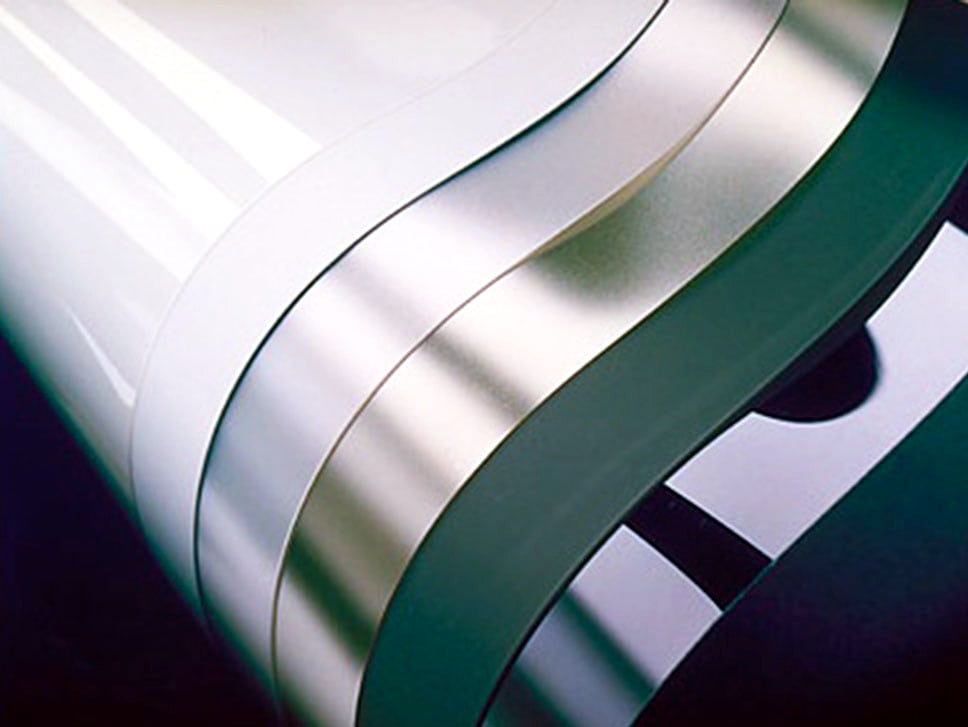

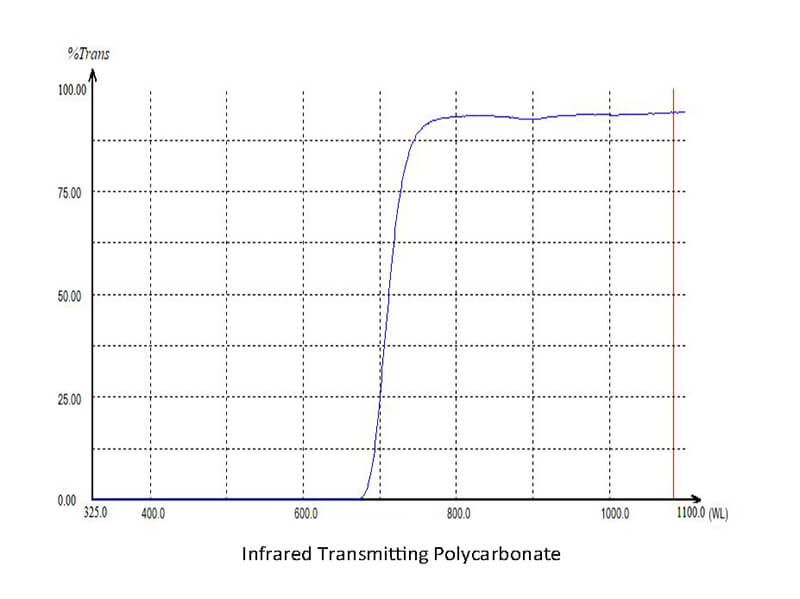

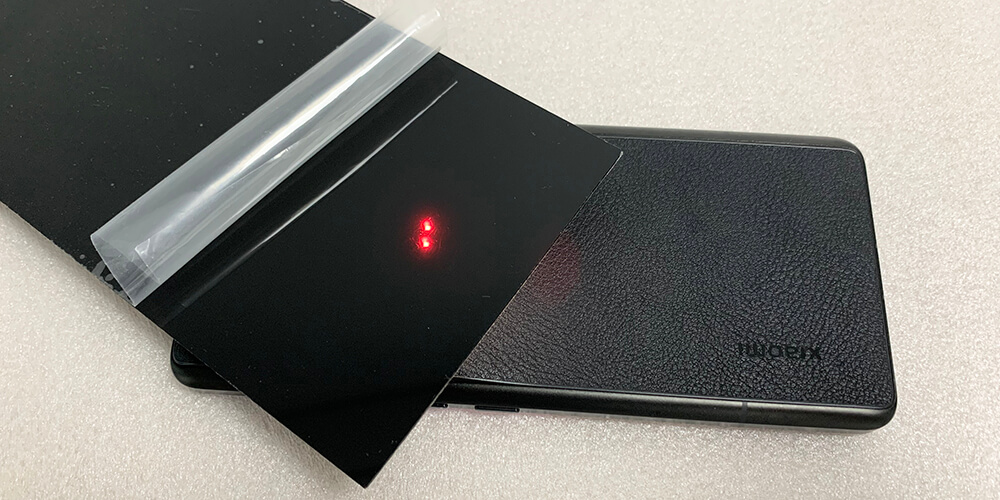

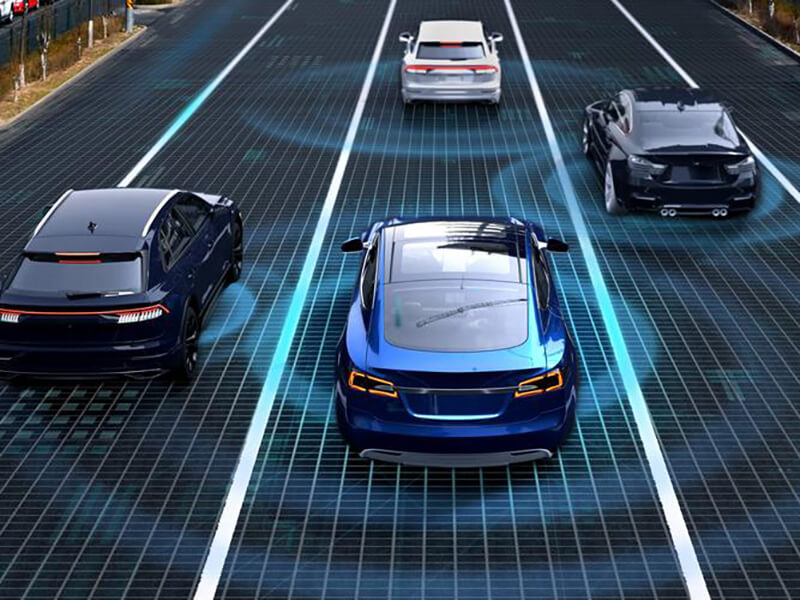

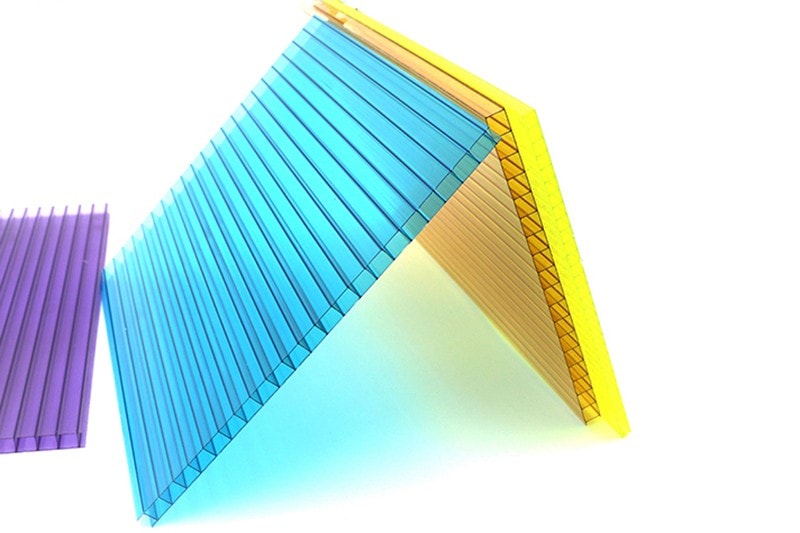

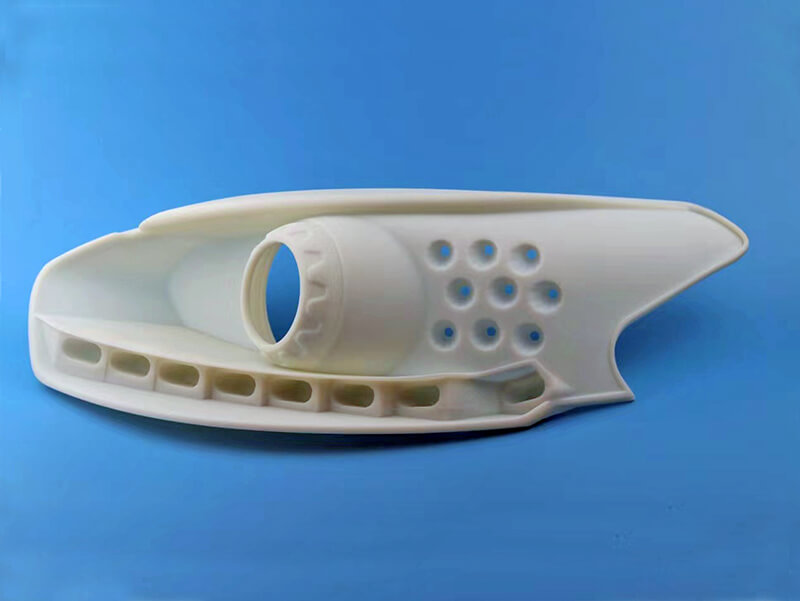

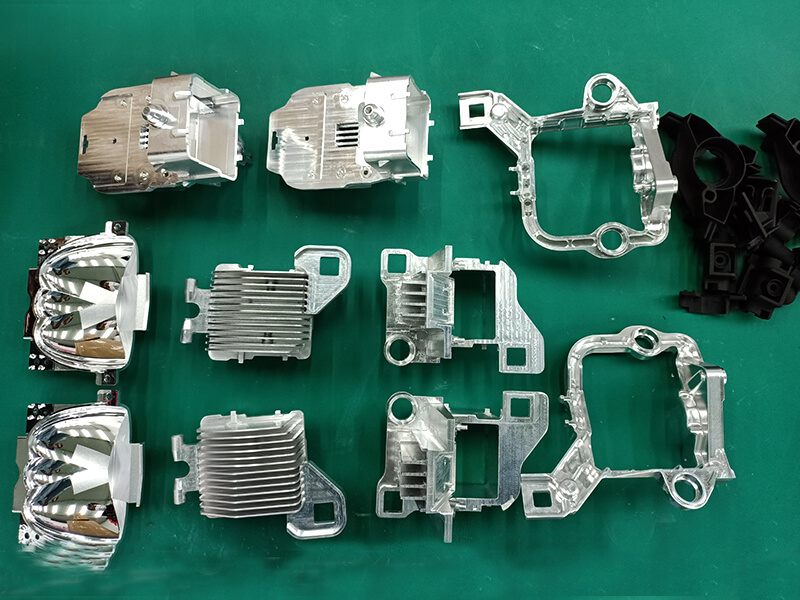

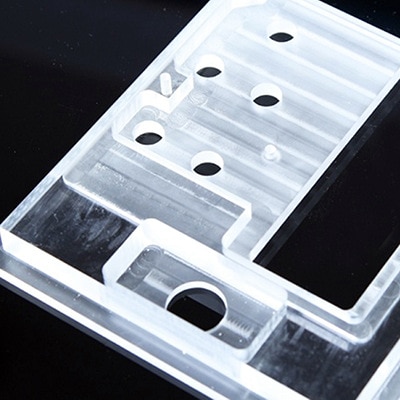

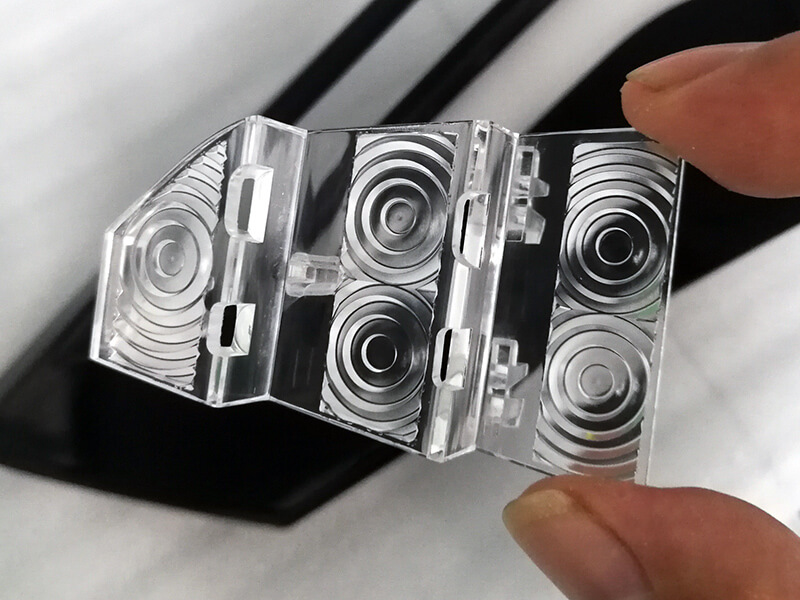

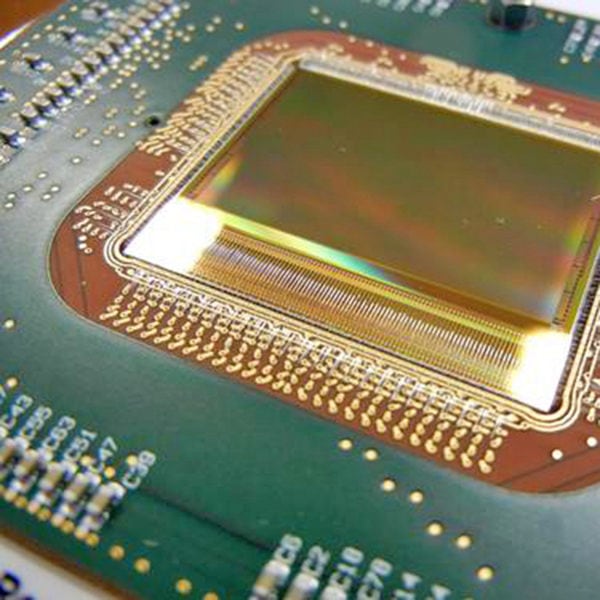

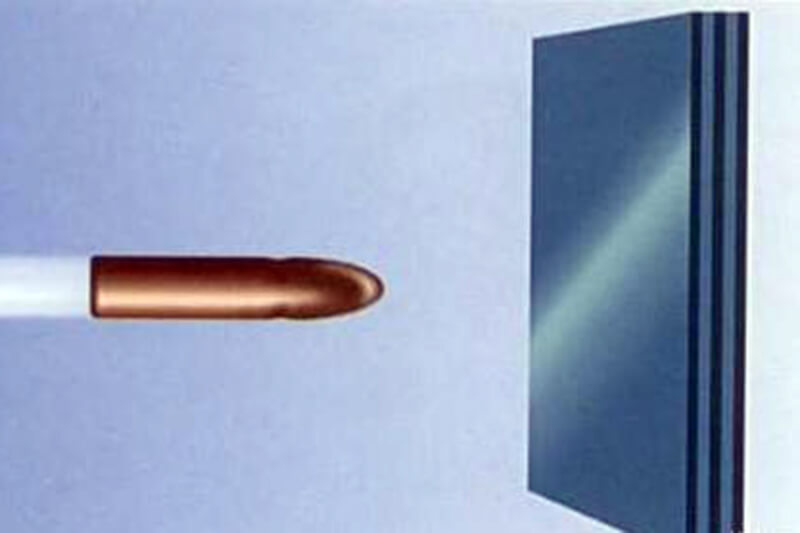

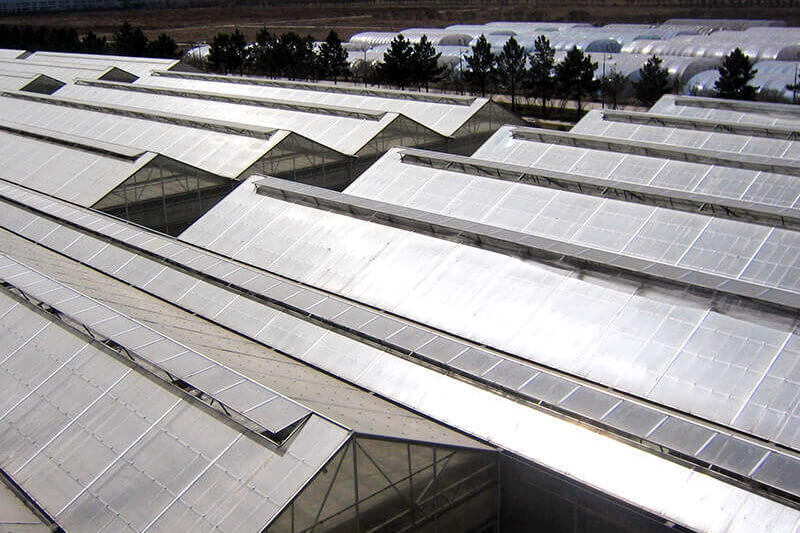

UVPLASTIC has been producing polycarbonate film since 2007, the thickness range is from 0.125mm to 1mm. With more than 13 years of effort and continuous investment in technology and equipment, we have grown to be the leading manufacturer of polycarbonate films in China. Today, we are offering a range of polycarbonate films, which meet a variety of application needs in instrument products, such as EMC/MRI shielding and EMI shielding window, lighting application, anti-fog lens product, LED/LCD display, the battery pack of electric automobile, etc.

UVTPC is the family code of UVPLASTIC polycarbonate films, which includes General-Purpose Film, Optical Grade Film, PMMA/PC Film, etc. All products are certified according to RoHS and REACH. UL certifications can be found under the UL global database. UVTPC polycarbonate film offers high-performance and helps clients to meet the changing needs in the market. It also helps OEM factories to create innovative designs with better functionality and environmental friendliness. Meantime, it keeps the competitive price.

Specification About UVPLASTIC™ Polycarbonate Films

Products Range

| Item | Model | Products Description | Application |

|---|---|---|---|

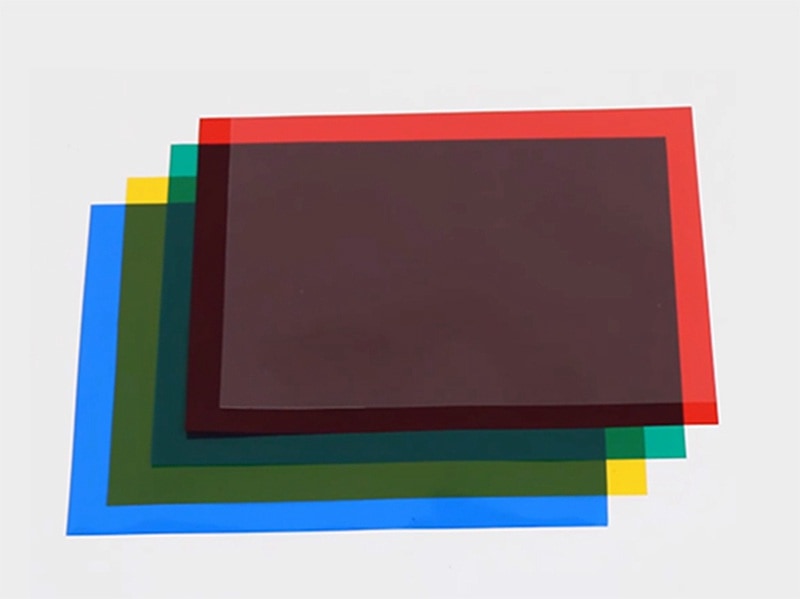

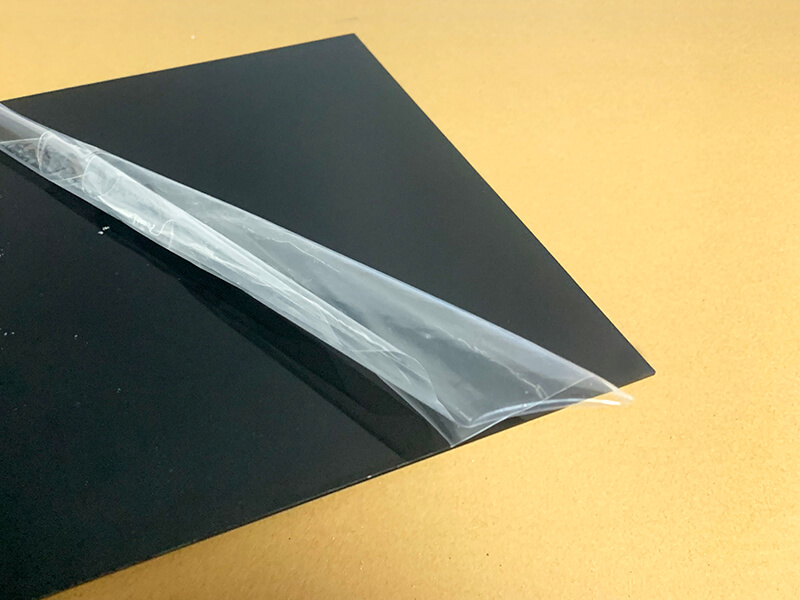

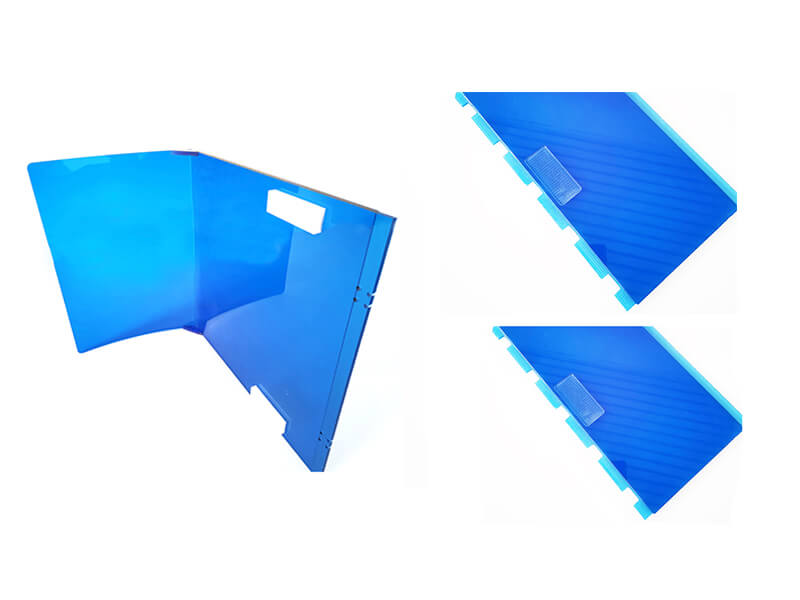

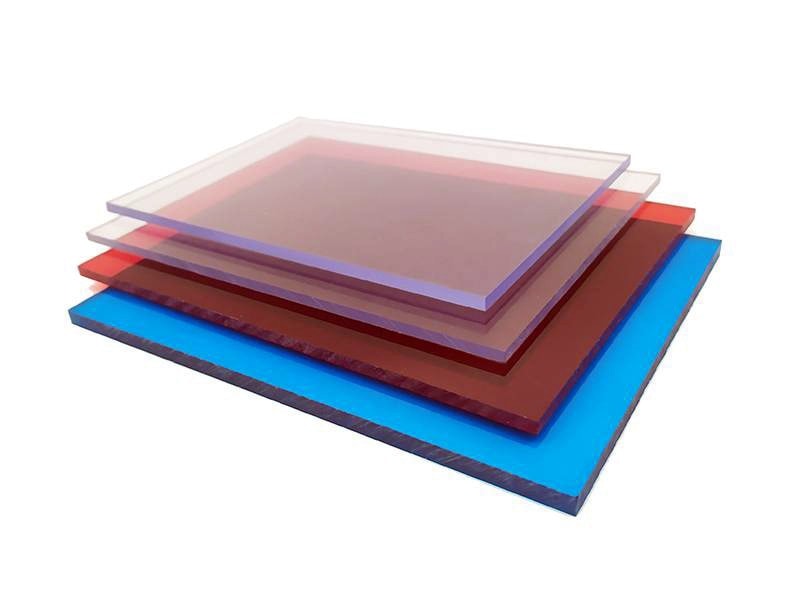

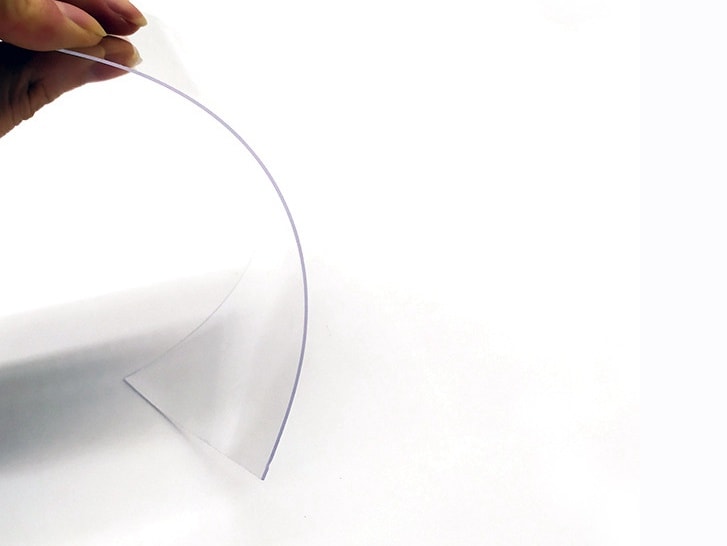

| General Purpose Polycarbonate Film | UVTPC-GP | Thickness is from 0.125 mm to 1 mm; Colors are transparent, black, and custom color; Flame retardant rating is V-2/UL94, VTM-2/UL94; Surface types are Glossy, Polished, Matte, and Frosted; Packaged as Sheet or Roll; | Sign, Luggage Case, Helmet, Membrane Switch, Visor, Eye Shield, Automotive Dashboard. |

| Optical Grade Polycarbonate Film | UVTPC-OP | Almost zero impurity, it is optically clarified; Thickness is from 0.03 mm to 3 mm; | Light Guide Plate; Automotive Dashboard; Or other coating film; |

| Flame Retardant Polycarbonate Film | UVTPC-FL | Flame retardant rating is V-0/UL94, VTM-0/UL94. Packaged as sheet or roll, Colors are transparent, black, and custom color. | Battery Pack; Fire Retardant Sign; |

| Blend Polycarbonate Film | UVTPC-BL | Two-layer or three-layer film by PC and PMMA, including PMMA/PC, PMMA/PC/PMMA, therefore, blend polycarbonate film has both advantages. | Smartphone, Furniture, etc. |

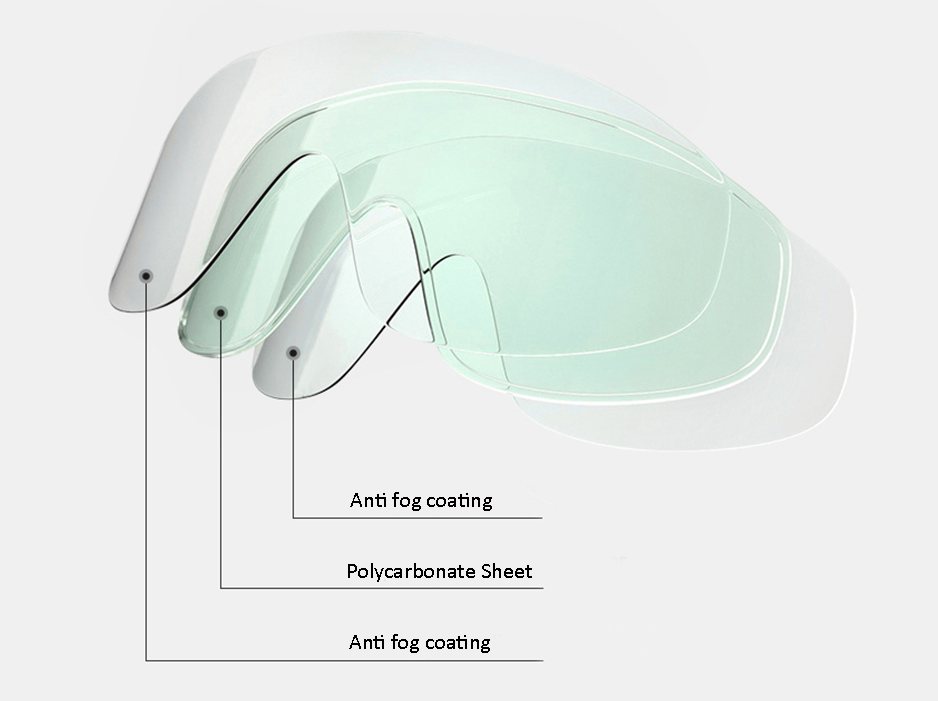

| Coated Polycarbonate Film | UVTPC-CO | Including scratch resistant polycarbonate film and anti-fog polycarbonate film | Sign, Front Panel, Visor, Eye Shield |

Dimension with Packaging as Roll

| Thickness (mm) | Width (mm) | Length (m) | UVTPC-GP | UVTPC-OP | UVTPC-BL |

|---|---|---|---|---|---|

| 0.125 | 1220 | 400 | ✔ | ✔ | |

| 0.175 | 1220 | 350 | ✔ | ✔ | ✔ |

| 0.2 | 1220 | 300 | ✔ | ✔ | |

| 0.25 | 1220 | 300 | ✔ | ✔ | ✔ |

| 0.3 | 1220 | 250 | ✔ | ✔ | |

| 0.375 | 1220 | 200 | ✔ | ✔ | ✔ |

| 0.5 | 1220 | 150 | ✔ | ✔ | ✔ |

| 0.75 | 1220 | 100 | |||

| 0.8 | 1220 | 100 | ✔ |

Dimention with Packaging as Sheet

| Thickness (mm) | Size (mm) | Size (ft) | UVTPC-GP | UVTPC-OP | UVTPC-BL |

|---|---|---|---|---|---|

| 0.3 | 1220×2440 | 4×8 | ✔ | ✔ | ✔ |

| 0.4 | 1220×2440 | 4×8 | ✔ | ✔ | ✔ |

| 0.5 | 1220×2440 | 4×8 | ✔ | ✔ | ✔ |

| 0.75 | 1220×2440 | 4×8 | ✔ | ✔ | ✔ |

| 0.8 | 1220×2440 | 4×8 | ✔ | ✔ | ✔ |

| 1 | 1220×2440 | 4×8 | ✔ | ✔ | ✔ |

Surface Type

| Surface Code | Surface Type | UVTPC-GP | UVTPC-OP | UVTPC-BL |

|---|---|---|---|---|

| 1 | Polished Type | ✔ | ✔ | ✔ |

| 2 | Fine Matte | ✔ | ||

| 3 | Fine Velvet | ✔ | ||

| 4 | Velvet | ✔ |

Different Surface Types of General-Purpose Polycarbonate Films

| Model | Thickness (mm) | Surface Type | Package Type | Transparent | Translucent |

|---|---|---|---|---|---|

| UVTPC-GP11 | From 0.125 to 4 | Polished / Polished | Panels, Rolls | ✔ | |

| UVTPC-GP21 | From 0.125 to 1 | Fine Matte / Polished | Panels, Rolls | ✔ | |

| UVTPC-GP31 | From 0.125 to 1 | Fine Velvet / Polished | Panels, Rolls | ✔ | |

| UVTPC-GP32 | From 0.125 to 1 | Fine Velvet / Fine Matte | Panels, Rolls | ✔ | |

| UVTPC-GP41 | From 0.125 to 1 | Velvet / Polished | Panels, Rolls | ✔ | |

| UVPC-GP42 | From 0.125 to 1 | Velvet / Fine Matte | Panels, Rolls | ✔ |

Physical Properties

| Physical Properties | Value | Unit | Test Method |

|---|---|---|---|

| Density | 1.32 | g/cm3 | ISO 1183 |

| Haze | <0.5 | % | ASTM D1003 |

| Light Transmission | 89 | % | ASTM D1003 |

| Tensile Strength | 60 | MPa | ISO 527 |

| Elongation | <50 | % | ISO 527 |

| Bend Strength | 90 | MPa | ISO 178 |

| Tensile Modulus | 2300 | MPa | ISO 178 |

| Surface tension | ≥34 | dyn/cm | Test fluid |

| Dielectric Constant | 3 | – | IEC60250 |

| Resistant Puncture Voltage | 30 | MV/mm | IEC 60243 |

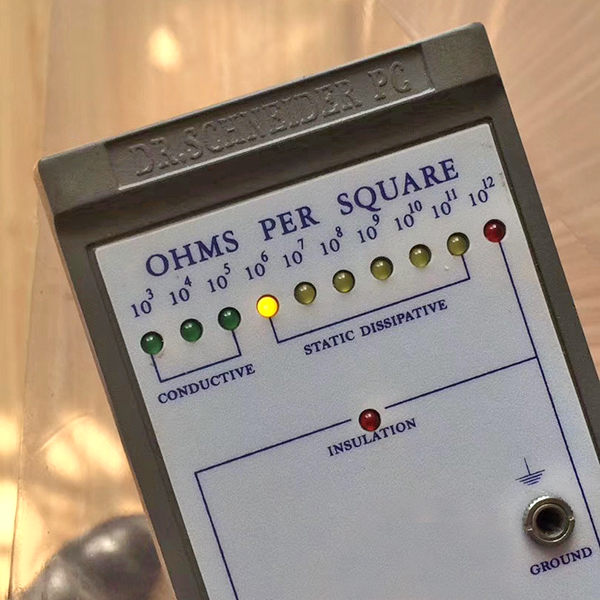

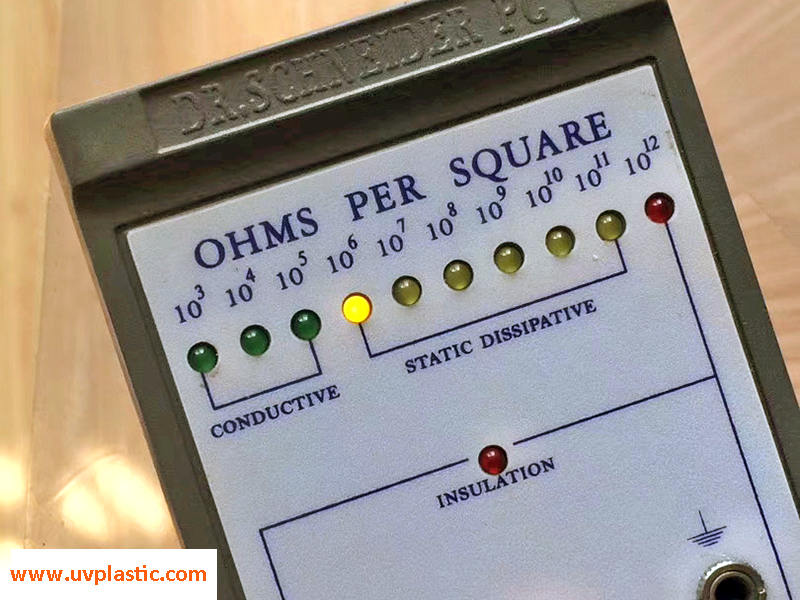

| Surface resistivity | 1.00E+16 | Ω/square | IEC 60093 |

| Volume resistivity | 1.00E+17 | Ω-cm | IEC 60093 |

| Coefficient of Thermal Expansion | 5.8 | ×10-5/℃ | ISO 11359 |

| Thermal Conductivity Rate | 0.2 | W/(m*K) | ASTM D5470 |

| Thermal Shrinkage | 0.5~0.7 | % | ASTM D1204 |

| Tg | 152 | ℃ | ISO306 |

Download

Certificates

UL Flammability Standard Released By Underwriters Laboratories

All UVTPC Polycarbonate Films meet the VTM-0, VTM-2 fire rating according to UL94.

Restriction Of Hazardous Substances

UVPLASTIC offers environmentally-friendly polycarbonate sheets and meets RoHS and REACH.

Related Products

Related Articles

Frequently Asked Questions

Need A Trustworthy Supplier Of Polycarbonate

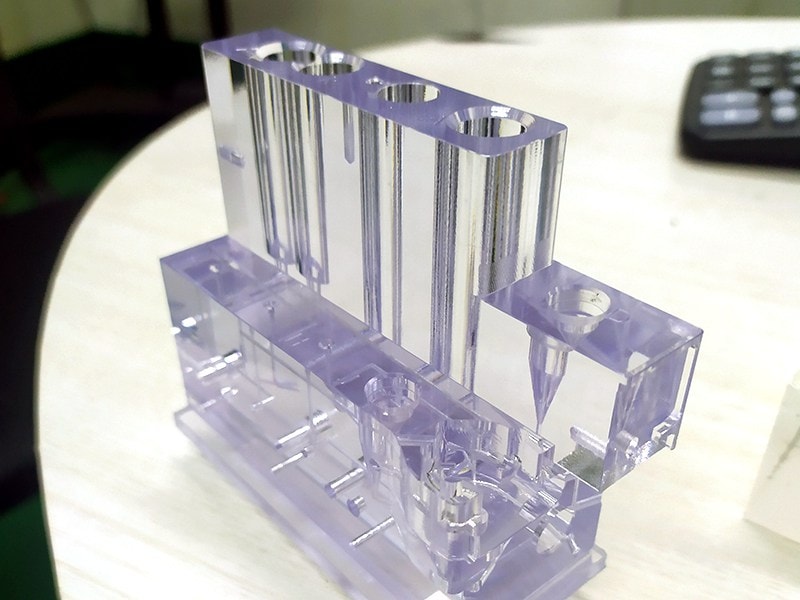

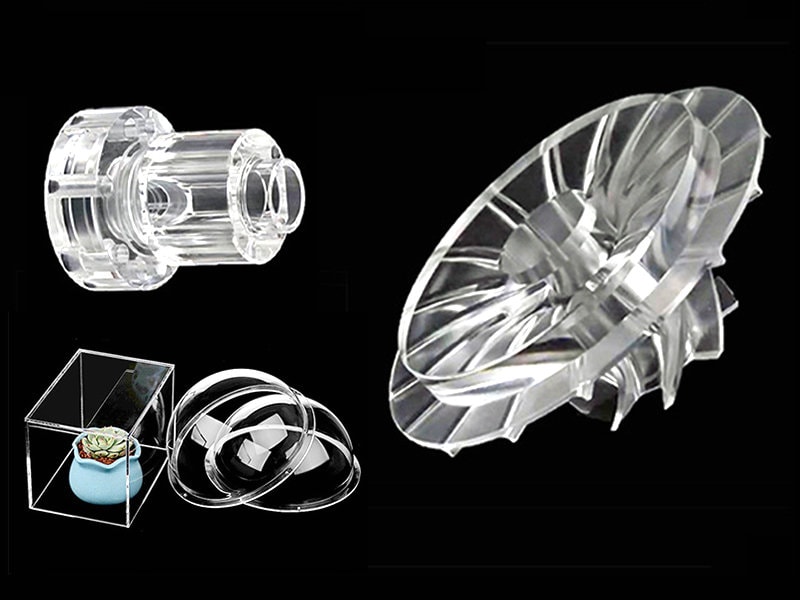

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.