Top Supplier of Infrared Transmitting Polycarbonate in China

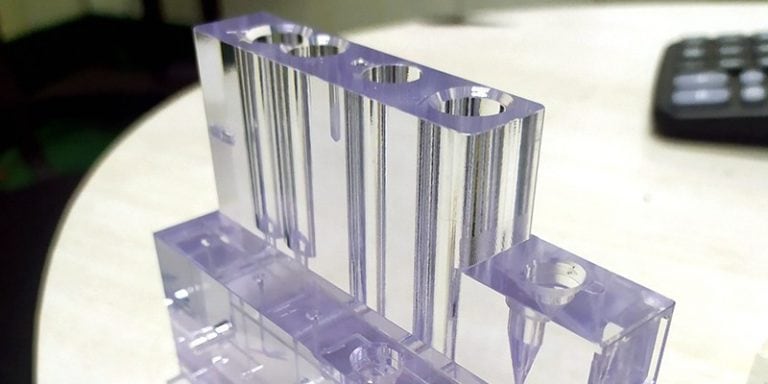

Infrared Transmitting Polycarbonate and Machining Service

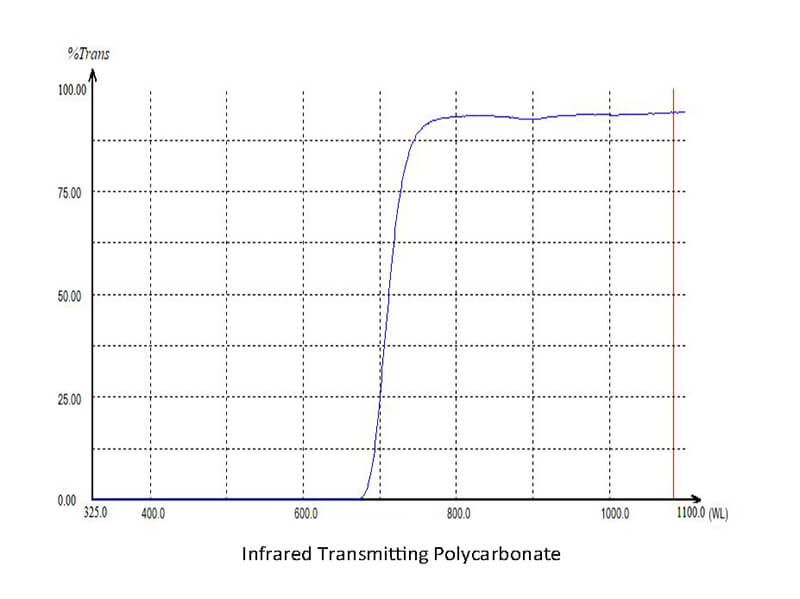

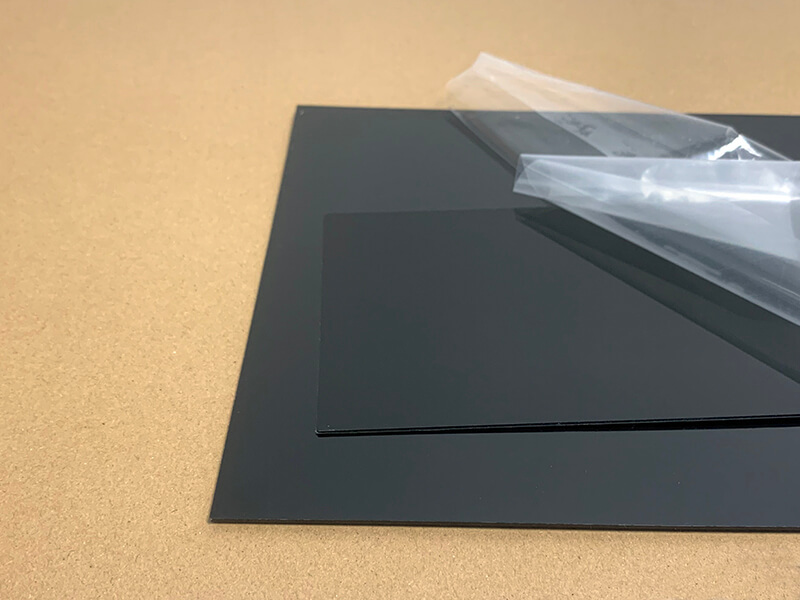

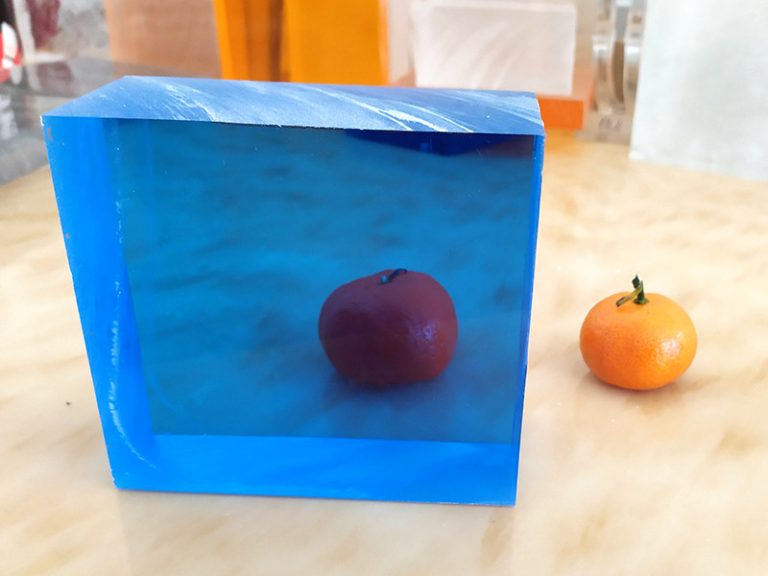

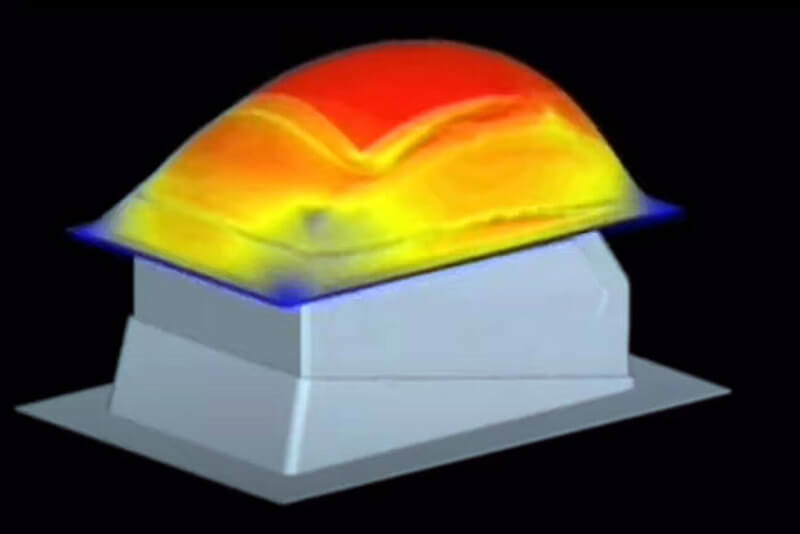

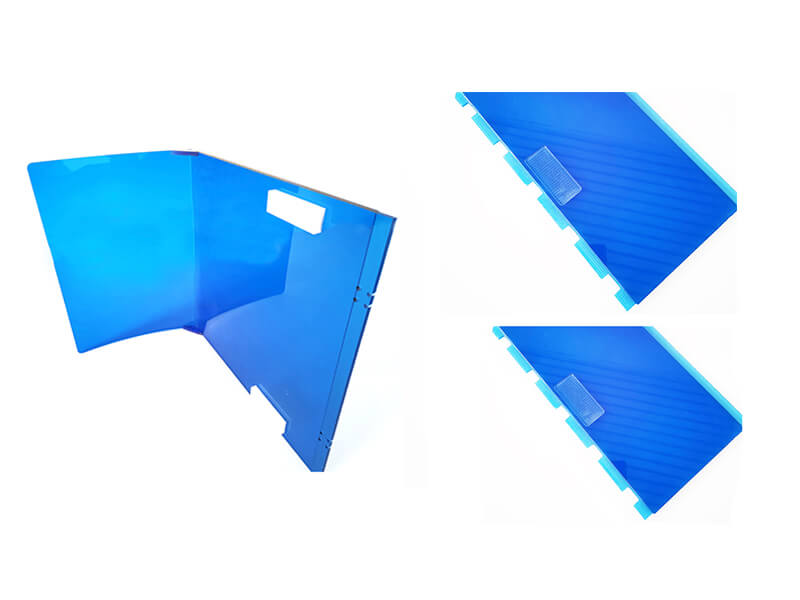

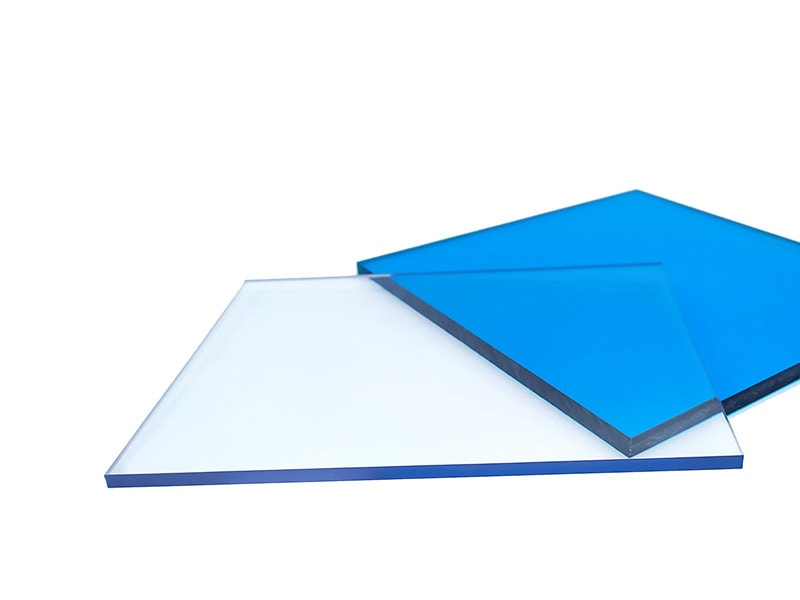

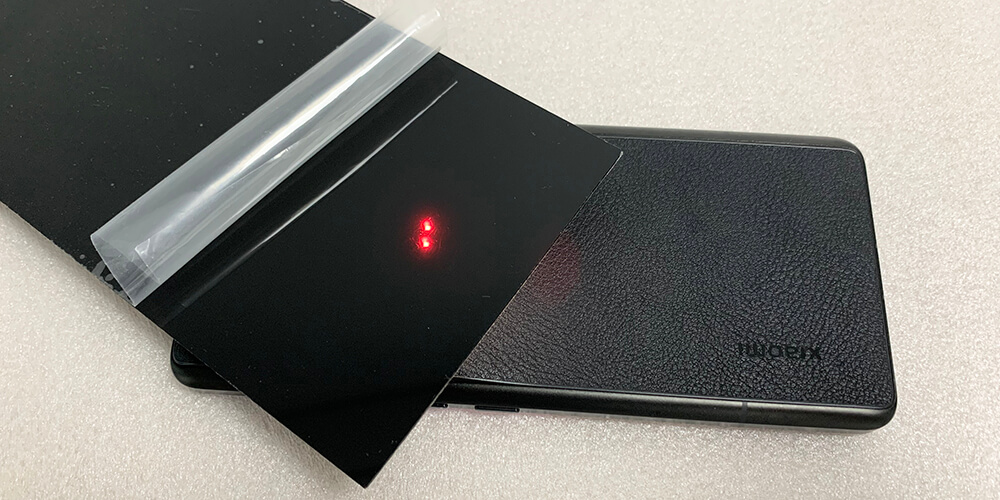

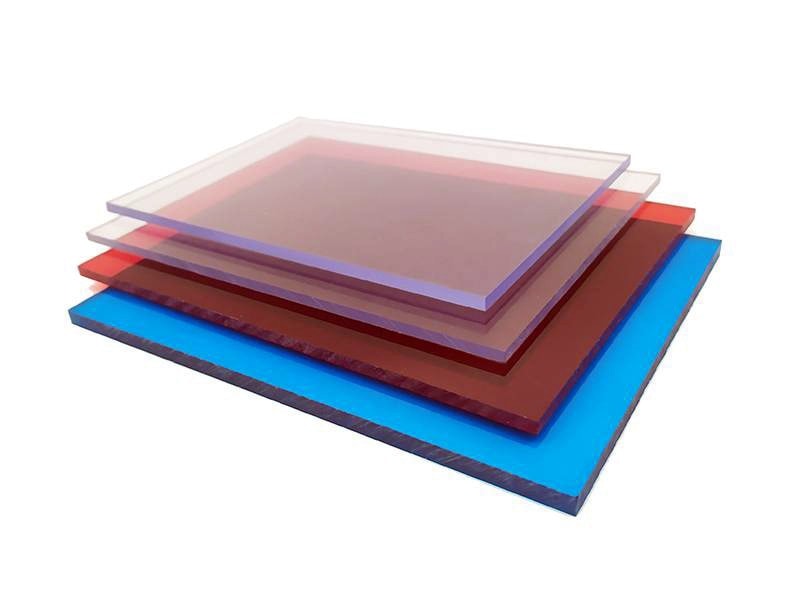

Infrared Transmitting Polycarbonate is designed to transmit infrared rays while blocking ultraviolet (UV) and visible light by the specifically formulated polycarbonate material, which some people call “IR Polycarbonate” or “IRT Polycarbonate.” Infrared-transmitting Polycarbonate is an opaque black plastic sheet that offers the same mechanical properties as a normal polycarbonate sheet but allows infrared light to pass through. Normally, It is recommended to be used for the transmitters and receivers of infrared rays, for example, Cameras, Rifle Optics, Sighting Devices, Unmanned Aerial Vehicles, Automatic Drive, Home Automation, etc.

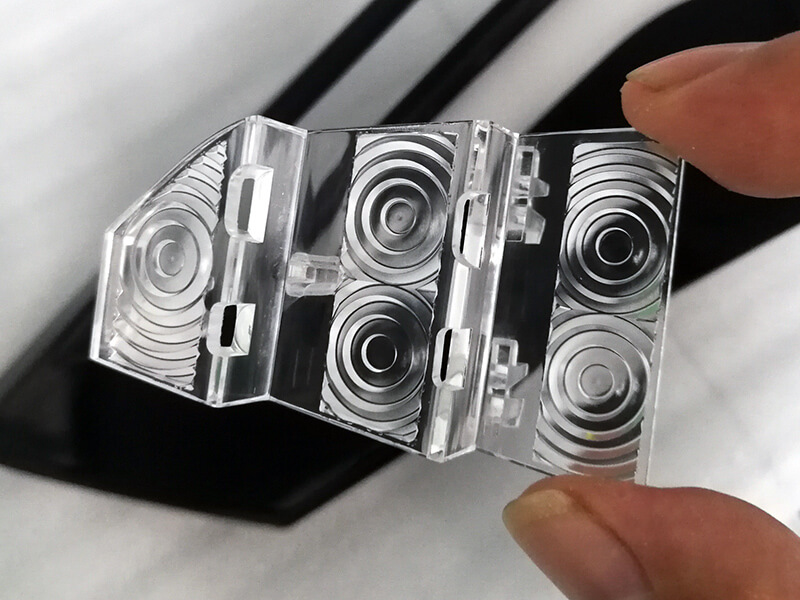

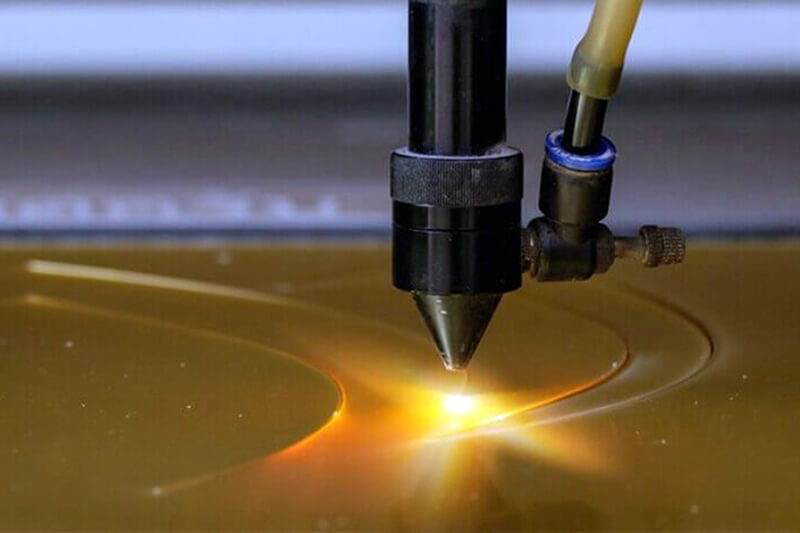

Compared with Infrared Transmitting Acrylic, Infrared Transmitting polycarbonate offers higher impact resistance, heat resistance, etc. UVPLASTIC offers Infrared Transmitting Polycarbonate sheets with thicknesses from 0.5mm to 3mm. Meanwhile, we also provide machining services, including Cutting to size, Die-cutting, CNC routing, injection molding, etc.

UVPLASTIC™ Infrared Transmitting Polycarbonate

Product Range

| Model | Product Name | Grade | Standard Thickness (mm) | Infrared Ray Transmittance (%) |

|---|---|---|---|---|

| UVFPC-IRT-700-N | Infrared Transmitting Polycarbonate | Normal | 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm | >88% (780~1100nm) |

| UVFPC-IRT-700-SR | Infrared Transmitting Polycarbonate | Scratch Resistant | 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm | >88% (780~1100nm) |

About UVPLASTIC IR Transmitting Polycarbonate

| No | Item | Description |

|---|---|---|

| 1 | Product Name | Infrared Transmitting Polycarbonate |

| 2 | Brande | UVPLASTIC |

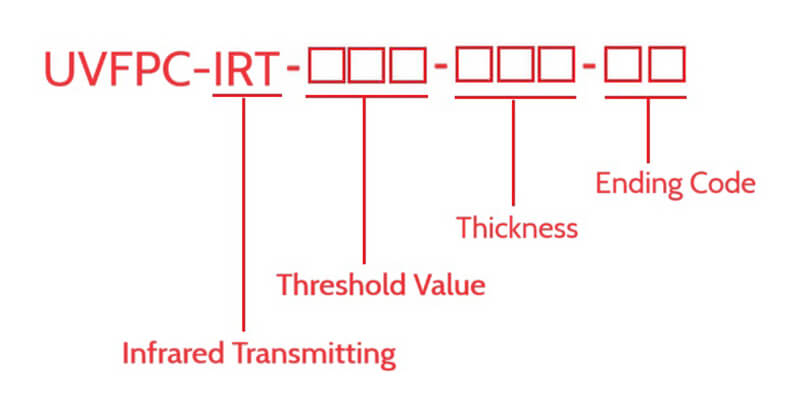

| 3 | Threshold Value | 570, 650, 700, 780, 800 Nanometer or Custom |

| 4 | Model | UVFPC-IRT-xxx-xxx-x |

| 5 | Infrared Ray Transmittance | >88% |

| 6 | Thickness | 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm |

| 7 | Transmission of Visible Light | <3% |

| 8 | Transmission of UV Light | <3% |

Model of IR Transmitting Polycarbonate

Properties

| Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Threshold Value Of Infrared Transmission (Standard product) | N/A | Nanometer | 700 |

| Infrared Transmission | 1mm thickness; 850 to 1100 nm; | % | >88 |

| Visible Light Transmission | 1mm thickness; 400 to 700 nm; | % | <1 |

| Refractive Index | ASTM D542 | 1.59 | |

| Melt Index | ASTM D1238 | g/10 min | 10 (300°C/5.0KG) |

| Density | ASTM D792 | g/cm^3 | 1.2 |

| Water absorption, 24H | ASTM D570 | % | 0.5-0.7 |

| Notch impact strength | ASTM D256 | J/M | 80 |

| Tensile Strength at Break | ASTM D638 | MPa or N/mm² | >630 |

| Elongation at break | ASTM D638 | % | 100 |

| HDT, 1.82MPa, 6.4mm | ASTM D648 | °C | 125 |

| Hot deformation temperature 1.80 MPa annealing | ISO 75-2/A | °C | 132 |

| Flammability | UL94 | / | V-2 |

| Surface hardness (Normal grade) | 750g | 2B | |

| Surface hardness (Scratch Resistant Grade) | 750g | HB |

Main Benefits

Application

UL Flammability Standard Released By Underwriters Laboratories

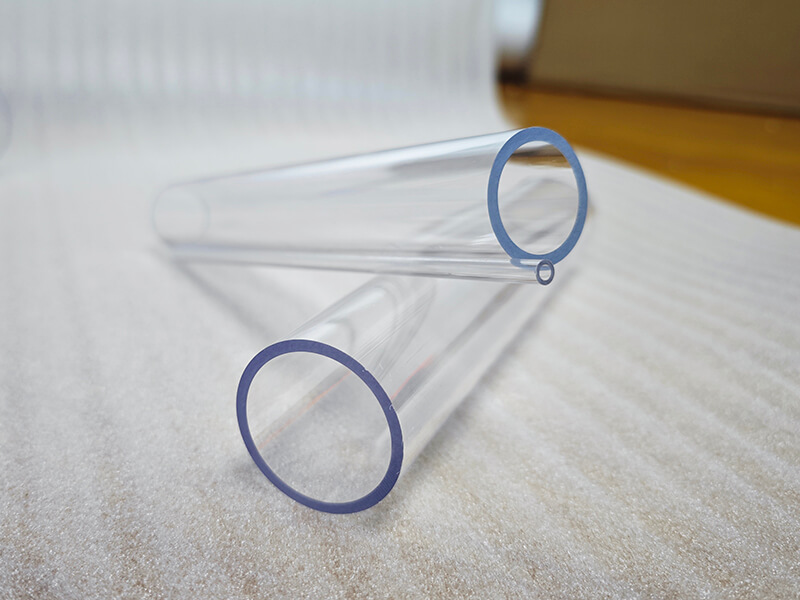

UVPLASTIC Polycarbonate Tube can meet the V-2 fire rating according to UL94

Restriction Of Hazardous Substances

UVPLASTIC offers environmentally-friendly polycarbonate sheets and meets RoHS and REACH

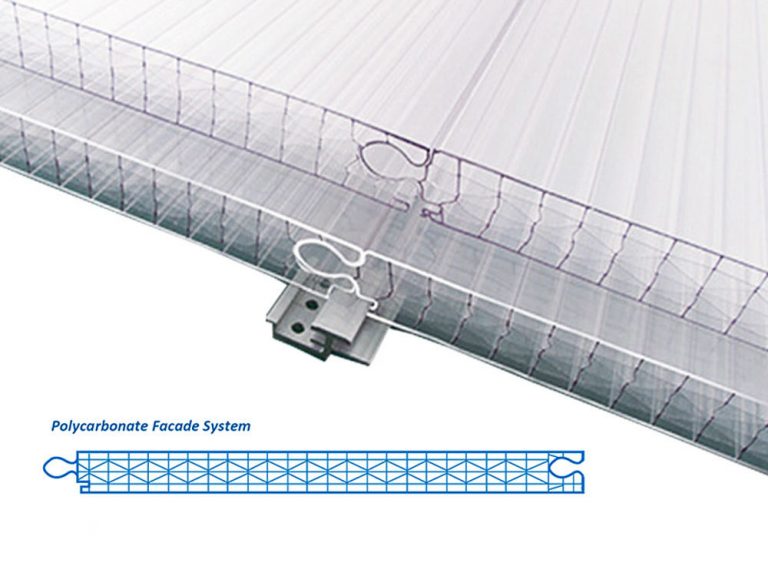

Related Products

Related Articles

Frequently Asked Questions

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.