Printing on Plastic, You need to Know

Related Machining Process

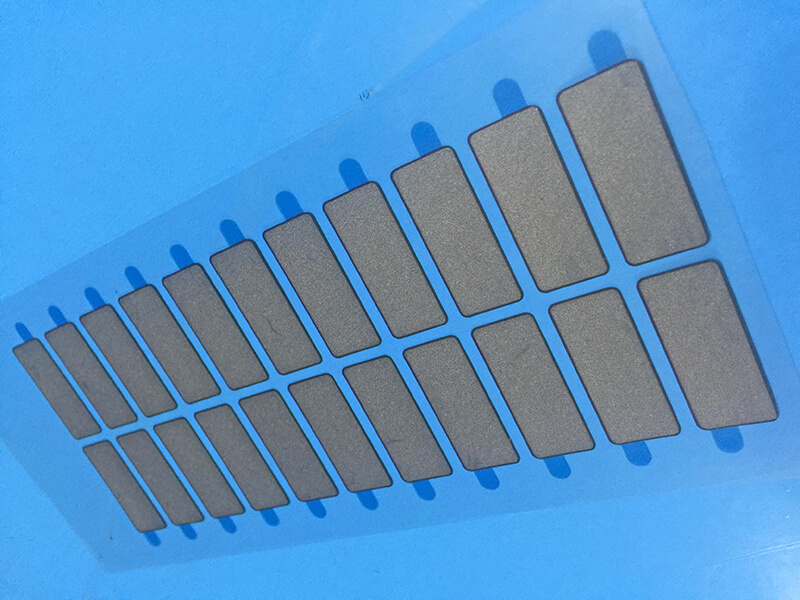

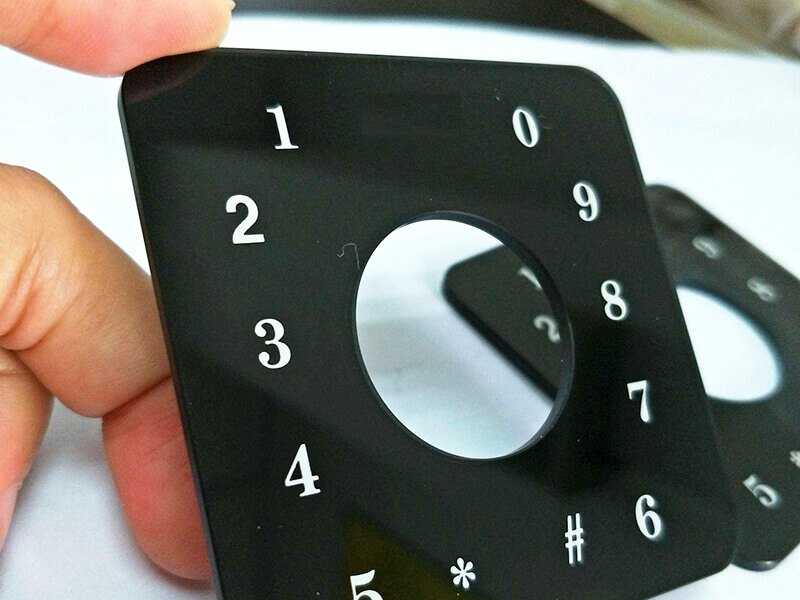

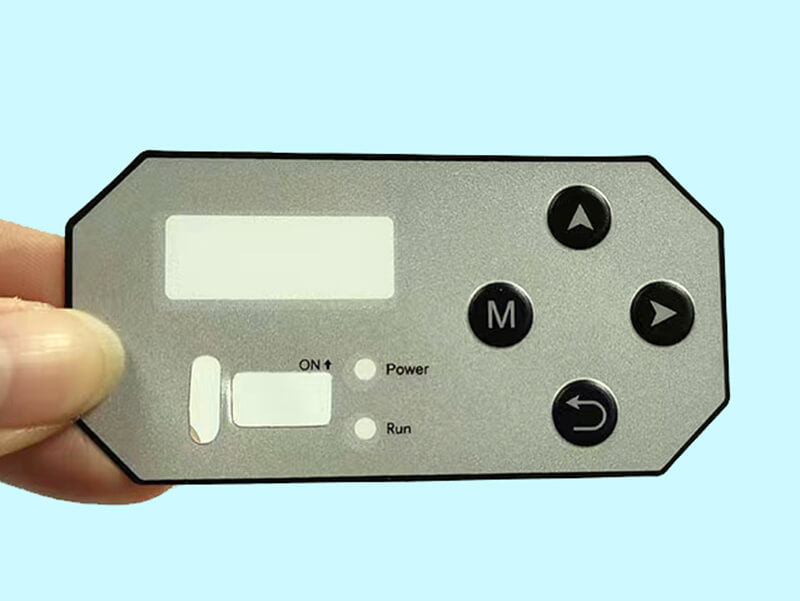

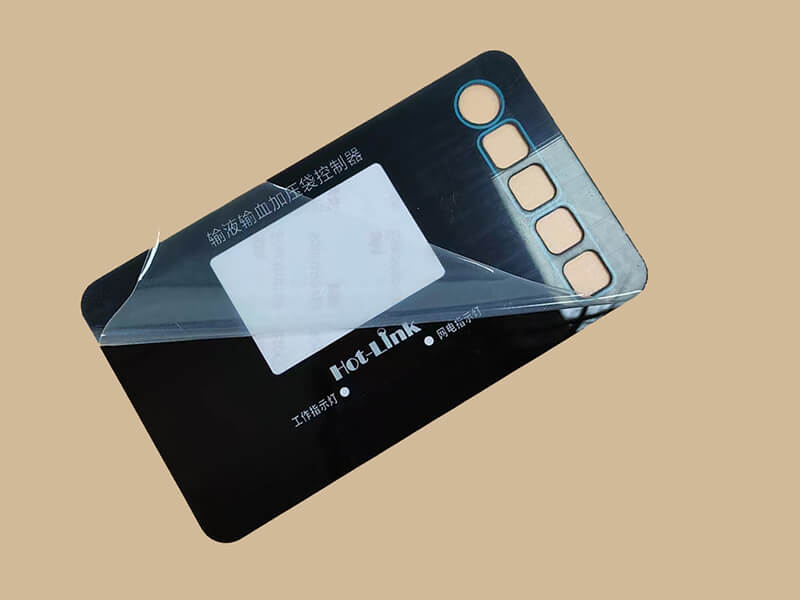

Printing on plastic is a necessary process to get custom graphic overlays for plastic parts, for example, membrane switches, display screens, custom labels, backlighting, and polycarbonate bus window. The most popular printing methods include silk-screen printing, digital printing, and so on. But which one is a good method for your products? And how to choose the supplier of printing service? Today, we will discuss it, let’s go ahead.

What is printing on plastic?

Printing on plastic is a method to get custom graphic overlays on plastic sheets, for example, polycarbonate sheets or films, PET, PVC, PETG, etc. The printed plastic with a graphic surface will be placed over the top of the internal electronics of a product. The main functions are the following:

Silk-screen printing on plastic

Silk-screen printing is one of the most popular printing methods, which is used by most companies for printing different overlays on products, including promotional bags, custom bottles, plastic display screens, ATV windscreens with polycarbonate material, etc.

Silk-screen printing has been used for more than 100 years, at the beginning, it is used for printing custom graphic overlays on T-shirts, bags, and wood. Today, silk-screen printing is suitable for most plastic with the development of technology, it is can be printed on a flat surface and cambered.

Material options for silk-screen printing

Screen Printing Equipment

In order to develop excellent graphic overlays on plastic, the following silk-screen printing equipment is needed:

Main benefits of silk-screen printing

Silk-screen printing on polycarbonate

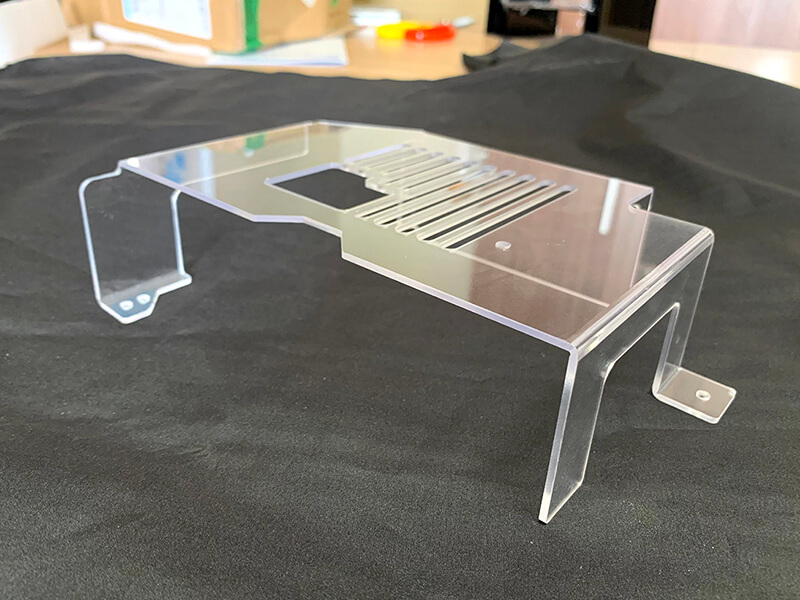

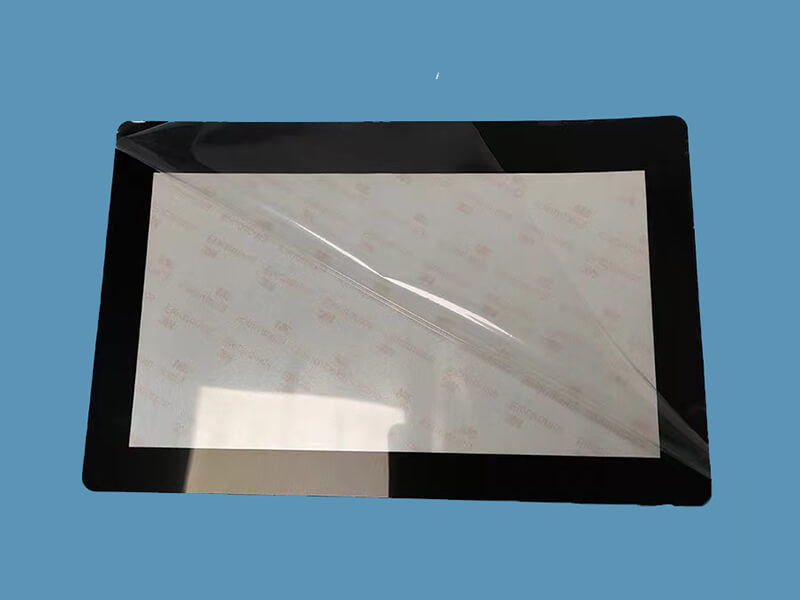

Polycarbonate (PC) is an unbreakable and shatter-resistant transparent material. This superior durability makes it a good choice across numerous industries beyond graphics. UVPLASTIC print on clear polycarbonate sheets and polycarbonate films. Large format printing on polycarbonate is also popular in retail, automation, and store verticals, where you can see polycarbonate sheets with custom graphic panels and signage. There are no clear substrates that can withstand the abuse that polycarbonate can. While it can scratch without special protections, it remains unbreakable. For this reason, membrane switch overlays and industrial labels are frequently made from polycarbonate. Otherwise, the following products will use polycarbonate sheets with custom graphics:

Digital Printing on Plastic

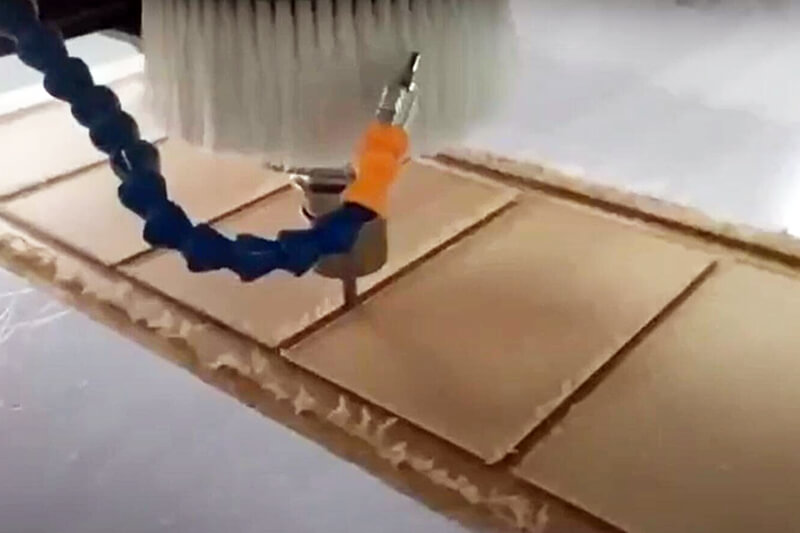

Digital printing plastic is a modern printing method by electronic files, like PDF, AI, TIFF, PSD, or other formats, which involves your artwork created by a computer and then printed directly onto your plastic material. Then, you can cut it as your route. It is an alternative to traditional methods such as silk-screen printing, it eliminates many pieces of equipment and working steps, such as making films and color proofs, manually stripping the pieces together, and making plates.

Benefits of Digital Printing on plastic

Printing on Polycarbonate

Polycarbonate (PC) sheet is a virtually unbreakable and shatter-resistant transparent plastic material. Therefore, it is one of the best options to be used in industries, for example, display screen protectors, and machine shields. UVPLASTIC is a trustworthy supplier, we use scratch-resistant polycarbonate. And we will screen print it and cut it according to your drawings. Polycarbonate is considered a good choice for printed signage and retail displays, because of its durability and outstanding longevity.

Why print on polycarbonate?

Polycarbonate was developed by Lexan in 1960, then, people printed on polycarbonate for a wide range of applications, but only silk screen printing was succeful. However, with the development of printing technology, other printing methods are suitable for it, for example, digital printing. No matter, what printing method you are using, polycarbonate is your favorite plastic due to its strength, durability, and ink adaptability. Compared with PETG, Plexiglass, polycarbonate is the most cost-effective material.

Conclusion

Now, you know more information about printing on plastic, but it is hard to print it by a person, you need a trustworthy supplier for your printing service, UVPLASTIC will be a good choice, contact us for a fast quotation.

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.