Polycarbonate Vs. Acrylic Machining

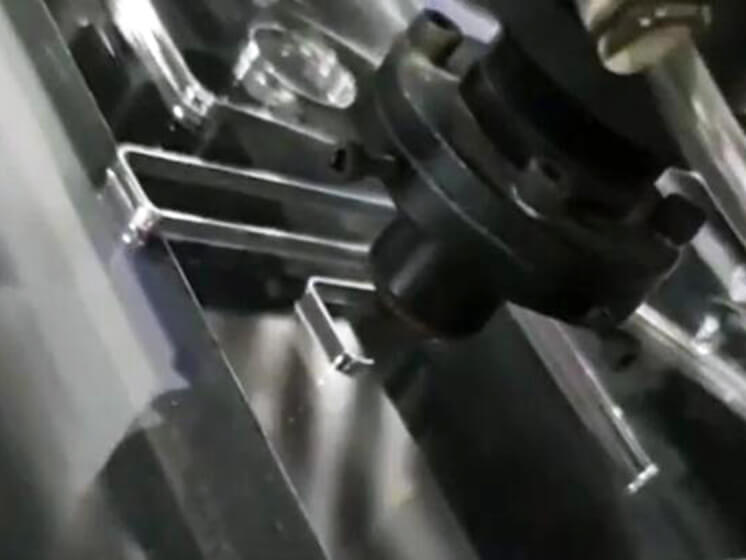

Machining is a process that shapes a material into the desired shape by removing elements from the workpiece. There are various machining methods such as drilling, milling, sawing, turning, and other methods used as per requirements.

Machining is used widely throughout various industries in the manufacturing sector. Many people think machining is suitable for only metallic objects.

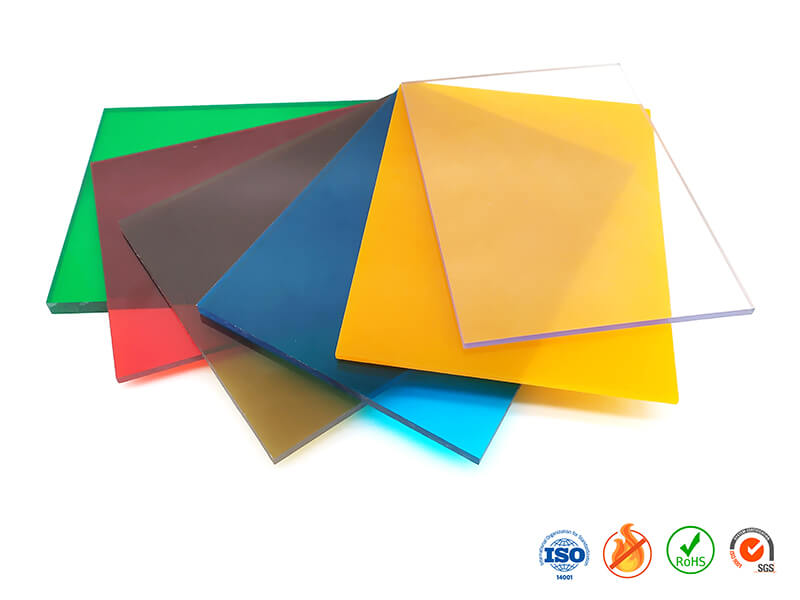

But guess what? Just like metal objects, various kinds of plastic material can be machined as well.

Today in this article, we’ll discuss the two most suitable plastic materials for machining, acrylic and polycarbonate plastic. Maybe, you need to know the difference between acrylic and polycarbonate.

So without further delay, let’s jump into the real thing!

Can polycarbonate be machined?

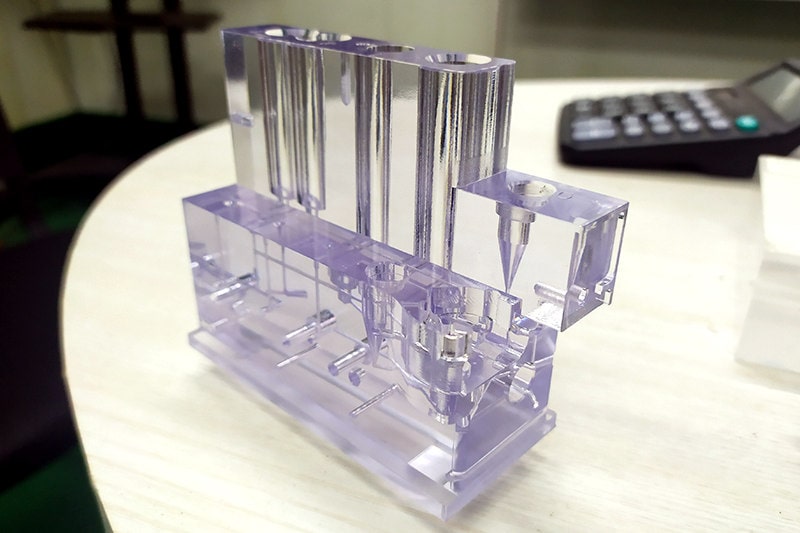

Yes, polycarbonate can be machined easily. It can be a perfect material for machining due to the extraordinary toughness and high impact resistance ability.

The milling process is the most suitable for this material. However, the cutting tool must be sharp enough to make the process smooth.

On certain exceptions, polycarbonate sheets can melt due to excess heat at the end of the process. Besides this, polycarbonate offers excellent machinability and you can choose it to machine and make any custom parts.

Can acrylic be machined?

Yes, acrylic can be machined, but cast acrylic is generally suggested over the extruded acrylic for machining. The extruded acrylic is not as rigid and it might crack at the machining. The cast acrylic does not break easily and offers better machinability.

Before choosing an acrylic sheet for machining, you need to be clear about a few facts. Acrylics are not very heat tolerant, so the cutting tool has to be very effective and sharp enough to avoid disappointments like poor surface finishing and material melting.

In some cases, it gets tough to maintain a smooth finishing for acrylic. Here are some of the most vital factors manufacturers should consider while machining acrylic:

Maybe, you want to know some machining mothods about machining acrylic, please see the following articles:

Polycarbonate vs acrylic machining

Polycarbonate is a bit easier to machine compared to acrylic. Acrylic is used as an alternative to glass, but this can melt at a lower temperature, so we need precautions while working on it. However, they both are used for industrial purposes.

Acrylic is more transparent than polycarbonate and acrylic is used as an alternative to glass. On the application of the polycarbonates, it might expand if it is allowed to sun exposure. A 3mm expansion is expected generally.

Ease of Use

Both of the materials offer great machinability. However, polycarbonate offers better machinability compared to acrylic. But you need to be aware of the applications too. Polycarbonate is easy to manufacture but cannot be applied everywhere.

Polycarbonate is a more natural choice for machining because it’s tough, rigid, durable and tolerant to heat. While acrylic is also a material that can be machined but we need to abide by specific rules while working on it.

Scratch and Crack

The acrylic might get cracked while machining, but there is no likely to have scratches on it. At the same time, the polycarbonate is quite the opposite. It can quickly get scratches on itself but won’t break easily.

Applications

Acrylic materials are used heavily in the automotive and aerospace industry, also used for the cars’ LED light and as glazing for clear components. It’s more prevalent in architectural operations because of its weather-resistant feature. Want to know the acrylic diffuser sheet.

Polycarbonate is more widely used in industries than acrylic materials as this is strong and tough. Polycarbonate serves industries like automotive, technology, electronics, agricultural, construction materials, niche applications, medical applications, phone companies, aircraft, spacecraft, military industries, and many more.

Cost

A single tool can be used for machining both acrylic and polycarbonate materials. The cost mainly depends on the plastic you choose for your parts.

There are multiple grades of plastics in the market for both cases. But in general, polycarbonate is roughly 35-40% more expensive than acrylic. So, all things being equal, acrylic machining is cheaper.

On the other hand, if the supplier can not use proper cutting acrylic methods, there might be more waste. In this case, the cost of acrylic machining will be higher.

Can we machine coated polycarbonate and coated acrylic sheet?

It depends on different situations and different coating methods. Firstly, I would like to explain why do you need to coating polycarbonate or acrylic? As we know that polycarbonate and acrylic sheets are excellent engineering plastics, but they can’t meet the requirement for some applications, for example, anti-static requirement, improved surface hardness, longer lifespan, etc. Therefore, we need to coat the layer on polycarbonate and acrylic sheet. Maybe, you want to know some coated products, please see the following list:

| Coating Layer | Polycarbonate | Acrylic |

|---|---|---|

| Anti-static/ESD | Anti-static polycarbonate | Anti-static acrylic |

| Hard Coated Layer | Hard Coated polycarbonate | Hard Coated acrylic |

| UV Coated Layer | UV Coated polycarbonate | / |

| Non-glare | Non-glare polycarbonate | Non glare acrylic |

| Anti-fog | Anti fog polycarbonate |

How to choose between acrylic machining and polycarbonate machining?

Choosing the right material is not that hard. The material you should use genuinely depends on your design and applications.

However, it might be daunting if you’re ordering for the first time. Don’t worry too much.

The best thing you can do is to consult with your manufacturer before placing an order. Make sure you’re communicating clearly with them and let them know your design and requirements. In general, if you prefer more transparent and lightweight parts, acrylic can be a great option. On the other hand, polycarbonate will be better for larger components that need more strength and impact resistance.

How UVPLASTIC can help with your machining project?

UVPLASTIC is a leading manufacturer of polycarbonate in China. We offer both acrylic machining and polycarbonate machining in our dedicated facilities.

So, no matter which material you wish to continue for machining, we can help! Make sure to reach out to us now for a free quote and ask us anything you want to know without any hesitations.

Final Thoughts:

Now that you know everything about machining these two materials let’s make a better decision. Which plastic will be a better option for your applications?

If you’re still not sure, give us a message and we will help you with any queries and information you need.