How to polish the edges of an acrylic sheet?

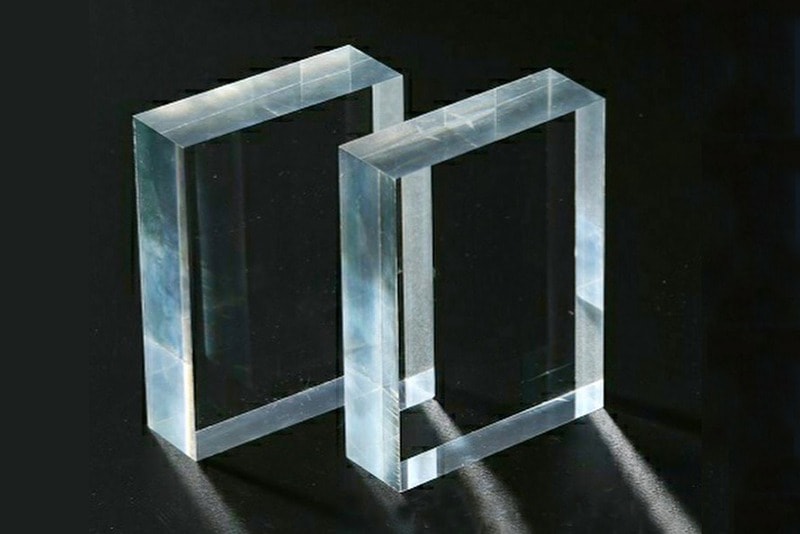

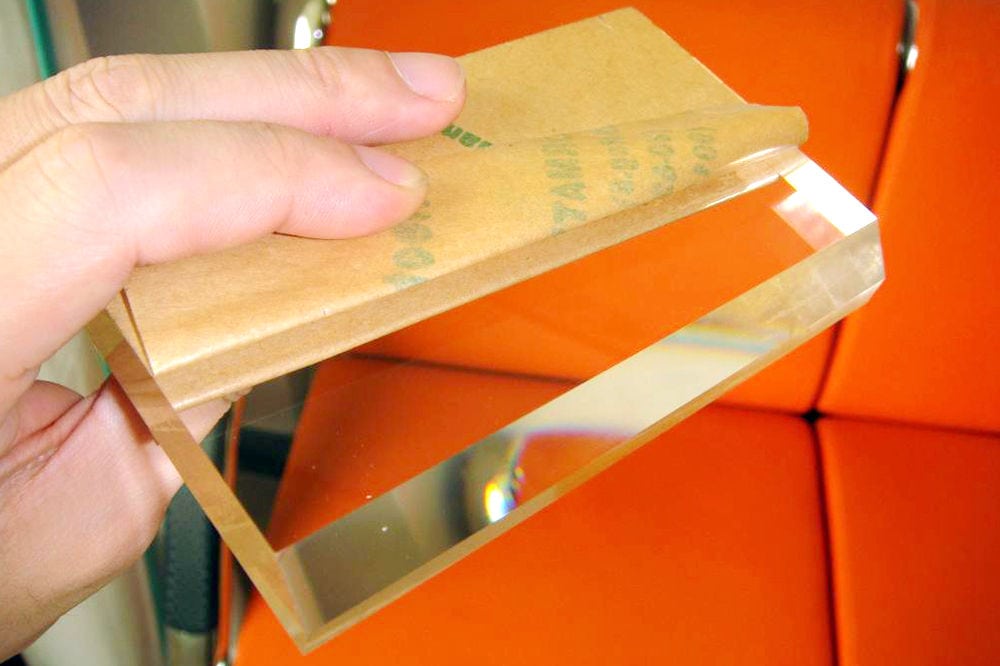

No matter how careful you were or which method you used to cut your acrylic, the edges still need finishing.

In this guide, I’ll show exactly how you can polish the edges of an acrylic sheet at home. So you have a clean and smooth edge to work on.

If you’re reading this, I assume that you already cut an acrylic sheet, or at least you know how to cut one, right?

If not, first check out our ultimate guide on how to cut acrylic sheet and cutting acrylic sheet.

Before we jump into the details, I’ll want to remind you of something you might already know.

Now that is out of the way, let’s jump right in!

Sanding Acrylic Sheet

Now that you have a sheet that needs a polishing around the edge. What is the first thing you need to do?

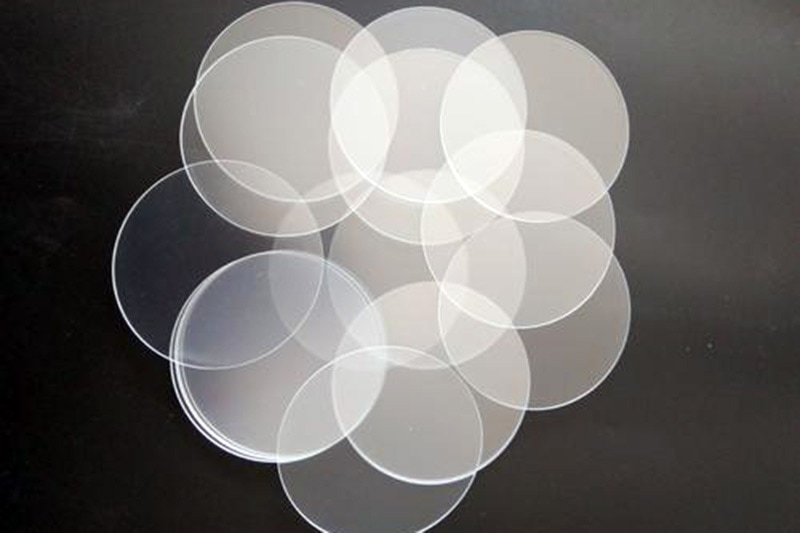

Sand Blasting is the process of removing surface deposits by applying fine glass beads at high pressure without damaging the surface. But for the plexiglass sheet, it just helps to get the frosted surface. It is like polishing acrylic.

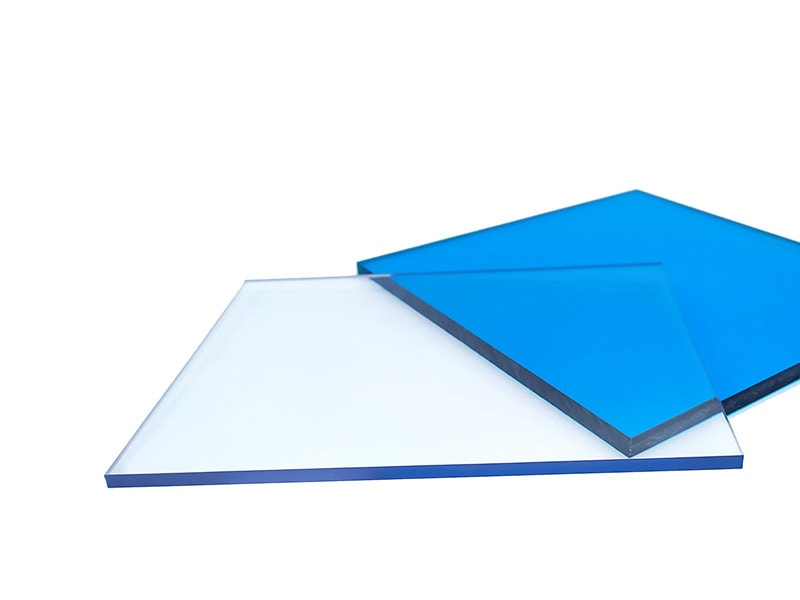

Like polycarbonate sheet, acrylic sheets can be sandblasted, How to sandblast it?

First, make sure you’re using clumps or any other method to keep the sheet still.

Second, get rough sandpaper, and you probably want to wrap it with some block or wood piece to make the strokes easier for you.

Once you’re ready, start sand the edge in long strokes.

Third, Once you make it a little bit more smooth than earlier, get finer sandpaper, and repeat the process with long strokes.

As I mentioned earlier, the cleaner the cut, the less time and effort it will be needed. This is why I can’t tell you the exact time it’ll need to have a smooth edge.

You should continue the process until you have a rough matt finish. And once you’re satisfied, move on to the next step.

Polishing Acrylic Sheet

Now that you have properly sanded the edges. It’s time to start polishing.

To do so, you’ll need a clean rag and some cleanser or polishing materials. There are various kinds of polishing materials specially designed for plastic items available in the market.

Now what you’ll need to do is put some paste cleanser on the rag. And then start to polish the edges with small strokes.

Continue the process until you have a smooth and polished edge.

Alternatively, you can also polish the edges with a hand drill, which can make this process even more comfortable and faster than above.

To use this tool, you have to start with low speed and apply light pressure on the edges.

Do not rush the process with excessive speed and put more pressure, which can damage the sheet.

You’ll want to check the result now and then and adjust the speed of your drill or how fast you’re moving it.

If you have never used a drill machine for polishing before, I recommend you try practicing on at least one or two sheets before you jump into the actual project.

And That’s it! This is how you polish the rough edges of an acrylic sheet.

Ralated Articles

Before we conclude, I want to share some more information that you might find interesting.

Conclusion

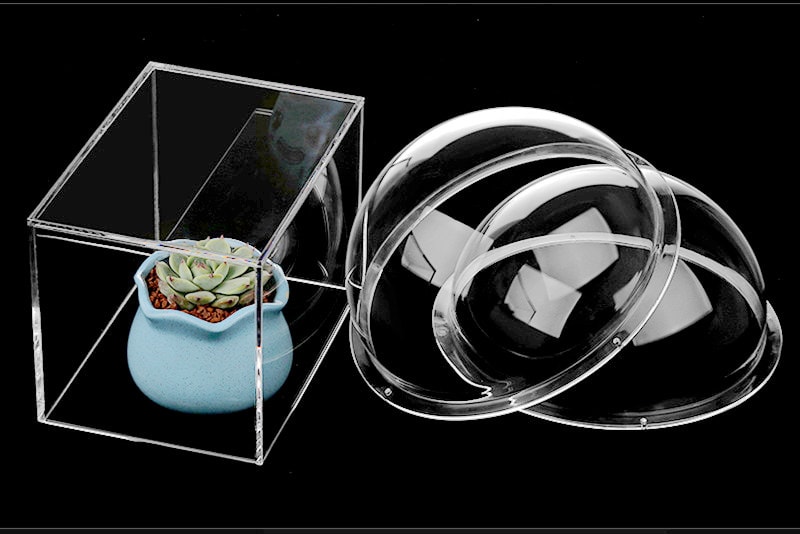

Acrylic sheets are becoming more and more popular nowadays. Because of its wide range of applications and DIY flexibility, people tend to love it more than ever.

Keep an eye out on our blog for the upcoming guides and tutorials about acrylic sheets and other exciting products.

Want to know more about machining acrylic sheet;

And if you have any suggestions and recommendations that you think would be helpful for you and others, please feel free to let us know. Your contribution will be highly appreciated.