How to drill, Bend, Clean Acrylic Sheet

If you’re a do yourself and love to do things yourself, this guide will give you hands-on experience on how to drill, bend, and clean an acrylic sheet.

Yes! All 3 in 1!

As we have a lot to cover, let’s dive in! First thing’s first.

How To Drill An Acrylic Sheet?

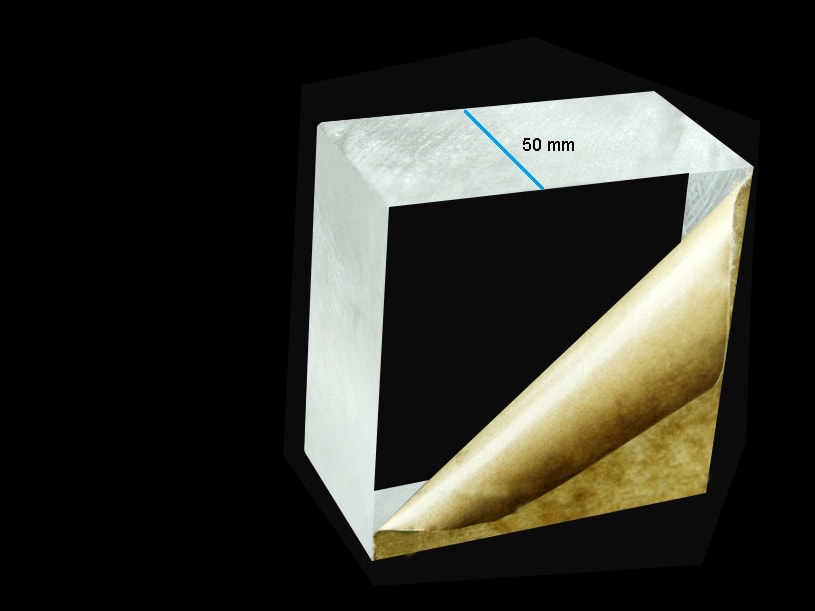

Unlike glass, drilling plexiglass is relatively easy and safe. The only thing you should be careful about is that these sheets can be scratched easily. This is why we recommend taking extra precautions and letting the protective film stay on the sheet while working.

Before you jump into actual work, let’s see the essential tools for this to work smoothly.

Drilling Acrylic

Step 1

Place a piece of wood or sheet beneath the acrylic to prevent chipping or damage the below surface. And make sure to use clamps or any other tool to keep the sheet steady and avoid any troubles.

Step 2

Mark the drilling position. Make sure the distance between the hole and edge is at least twice the thickness of the drill. This will avoid any chipping or cracking while drilling a hole near the edges.

Step 3

Start drilling with light pressure and medium speed. Before that, you might want to try and test the speed on broken sheets to be sure. Applying heavy pressure or high speed can damage the sheet.

If you’re not sure about the right speed, here’s a quick guideline for you:

| Drill diameter | Speed (RPM) |

|---|---|

| 1/8″ (3 mm) | 3,500 |

| 3/16″ (4.5 mm) | 2,500 |

| 1/4″ (6.0 mm) | 1,800 |

| 3/8″ (9.5 mm) | 1,200 |

| 1/2″ (12.7 mm) | 900 |

| 5/8″ (16.0 mm) | 700 |

| 1″ (25.4 mm) | 450 |

Step 4

If you’re working with a sheet thicker than ¼” use water as a lubricant to avoid melting. Pull up the drill when necessary and clean the hole.

Step 5

Keep a steady and slow pace until the drill bit is gone correctly through the whole length.

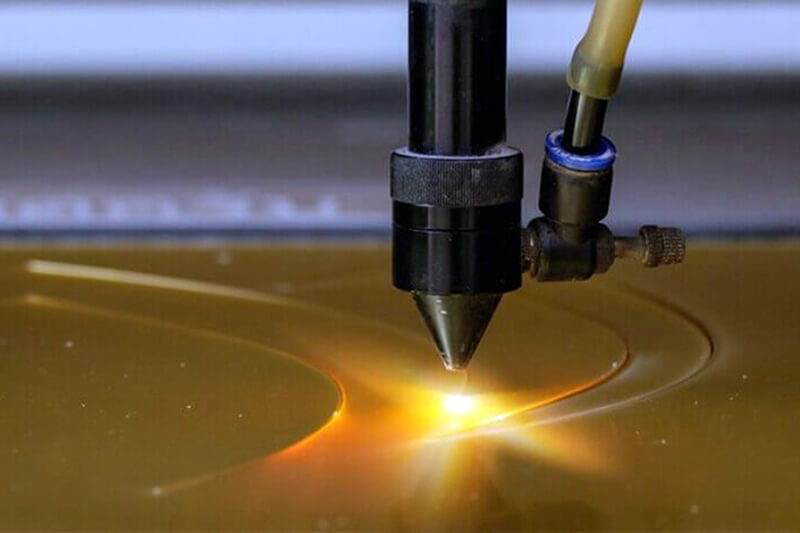

Drilling acrylic by engraving machine

If you need a very precise hole, you need to use an engraving machine, the tolerance will be 0.05 mm. Of course, you can use a laser cutting machine to drill it. If you are looking for a supplier of drilling acrylic, UVACRYLIC will be the best one.

Related Blogs

How to Bend Acrylic?

Bending the sheets can open up a whole new world of applications, especially with DIY projects… You probably already know the applications and even use many of those. But here, you’ll see how you can do it as well!

So, let’s dive right in!

Bending Smaller Sheets

If you’re working with relatively small sheets, then you can follow this process:

Tools needed

Now the nitty-gritty.

Step 1

Cut the sheets into desired sizes and peel off the protective peels on both sides of the acrylic.

Step 2

Fire up your stove and place your acrylic above the stove. Don’t put it too close to the fire as it can mess up the sheet with many bubbles. Place it at a safe distance and make sure the desired bending line gets the heat equally on the surface.

The required time you have to heat the sheet is largely dependent on the thickness and size of your sheet.

Step 3

Once the sheet is well-heated, place it between two scrap wood and use another plywood piece to apply pressure in your desired direction.

Step 4

Let the sheet cool off before doing anything.

Bending Large Sheets

Bending bigger sheets is slightly different, but the process is almost the same.

Tools needed: Heat Gun, Scrape woods, Clamps.

Let’s see how it’s done.

Step 1

Put the acrylic between two scraps of wood and clamp it strongly. Make sure the desired bending line is right out of the edges.

Step 2

Fire up your heat gun and apply heat from one side to another, ensuring all the area gets equal heat. When the sheet has enough heat, it will begin to bend automatically.

Step 3

Apply pressure to your desired direction.

You’ve learned how to drill and bend an acrylic sheet so far. Now the final part.

You can know more detail about bending acrylic sheets. Click HERE to find a supplier of bending acrylic service.

How to Clean an Acrylic

Cleaning the acrylic sheet is much easier than cleaning glass materials. But you have to be careful about the scratch, though. In this guide, I’ll show you exactly how to clean your acrylic sheet without leaving scratch marks.

Before we jump on to how to clean them, first, let us take a look at what we should NOT do!

Although acrylic sheets are pretty solid materials, they are quite vulnerable to certain chemicals. Avoid any abrasives, window cleaners, or chemicals that have alcohol or ammonia. These products can severely damage your sheets.

Step 1:

Before you start cleaning, it’s essential that you first examine the dust level of your sheet. Sometimes you only need a microfiber cloth and some water to do the cleaning if the dust is relatively lower, and sometimes you need to use acrylic cleaner sprays to have a proper cleaning.

Step 2:

It’s better if you can blow the dust from the surface with an air blower. This will make the process safer as rubbing the surface with dirt on it can scratch the sheet.

Step 3:

Get a non-abrasive microfiber cloth and a bowl of water. Ensure the piece of fabric is clean and you’ve never used it for cleaning anything else in the house.

Step 4:

Sprinkle some water on the surface and gently sweep the cloth. Make sure to rotate the cloth after 3-4 strokes to keep the clean part on the sheet surface.

Step 5:

If the dust is strong and needs more special care, use soapy water or any non-abrasive cleaners that DO NOT contain ammonia or alcohol in them. Wet your cloth and sweep gently until the dust is cleaned off.

Step 6:

After the cleaning is done, do not wipe the sheet. Let it dry naturally.

Conclusion

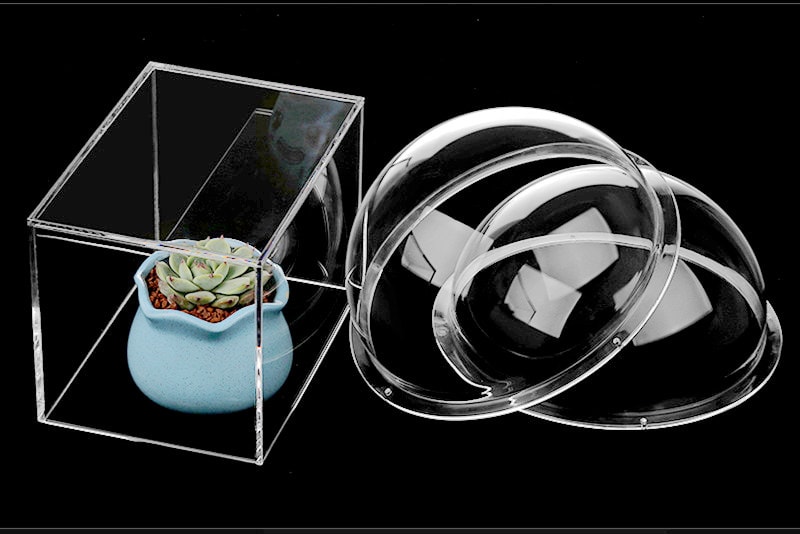

In this guide, we tried to answer and give you the best possible method for the three most asked questions about acrylic sheets. Maybe you need to know about Custom Acrylic.

People, especially DIY-ers, are becoming more and more attracted to acrylic sheets over the years because of their wide range of applications.

UVACRYLIC is a subsidiary of UVPLASTIC, which is a trustworthy supplier of acrylic sheets, otherwise, provides acrylic rod, acrylic tube, solid acrylic block, etc.