Prototyping Company: A Complete Guide For Beginners

Do you have a business idea that you intend to sell on the market? Are you worried about whether the idea will work out there in the competitive world? Prototyping brings you the opportunity to test your successful idea in real life rather than estimating.

What is a Prototype?

In today’s world, small businesses are accelerating rapidly. But the number of successful businesses remained small. That’s because it’s not easy to build a business and help it become a successful one. To do so, one needs to be smart and practical.

Prototyping is one of the primary, yet crucial steps in the invention process of a business. You can define it as the three-dimensional version of your vision that gives your idea a tangible form. It is not only a functional adaptation of your product but you can also use it in a real-world scenario to test and get reviews and feedback before you launch it into the market.

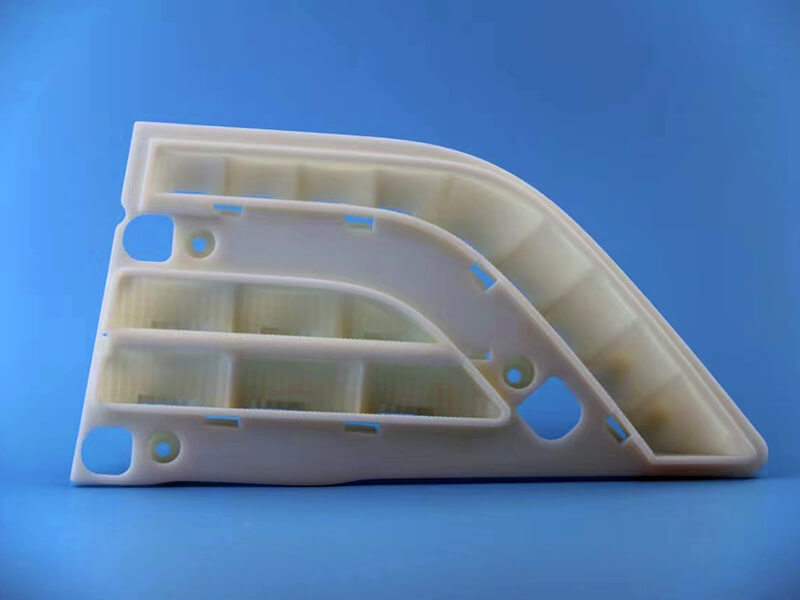

Although prototyping is a major part of design thinking in the manufacturing industry, it can be used by all types of industries. You can do a rough sketch on the paper creating an interactive simulation that looks like the finished product, or you can use high-quality, sophisticated materials, depending on your idea, goals, and budget.

Types of Prototypes

Prototypes can vary depending on product ideas and budget. They can mainly be of four types, each with different characteristics and suited to test different things. If you try using the wrong type of prototype, there is a high chance that you’ll get into trouble.

The Three types of prototypes are:

Feasibility Prototypes

This is essential when you’re creating new technology. You need a simulation of the concept. These prototypes are to understand or address any technical risks during product discovery. Helps to learn if a product is feasible or not.

Low-Fidelity User Prototypes

Low-fidelity prototypes do not look real at all. Rather they are one-dimensional simulations created to test the workflow and understand any usability issues.

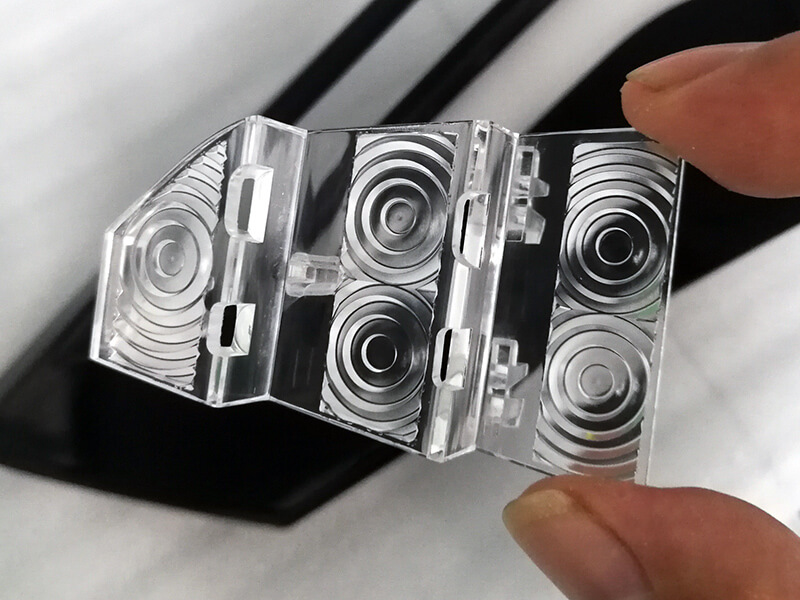

High-Fidelity User Prototypes

High-fidelity prototypes are more realistic-looking. Sometimes, if you can create it perfectly, it can get difficult to know that it’s not the real product. This allows the users to get a feel of how the final product would look like.

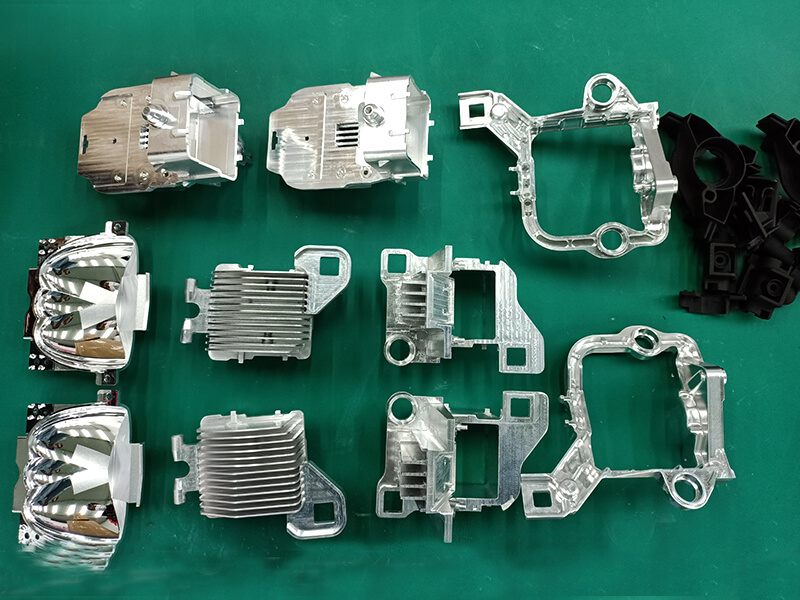

What Does a Prototyping Company Do

As you know by now, prototypes are essential, and so are prototyping companies. These companies offer prototyping services, often production services alongside. They will create a draft version of your idea during product development. You can use them for feasibility testing, demonstration, investor pitches, market research, production run-throughs, etc.

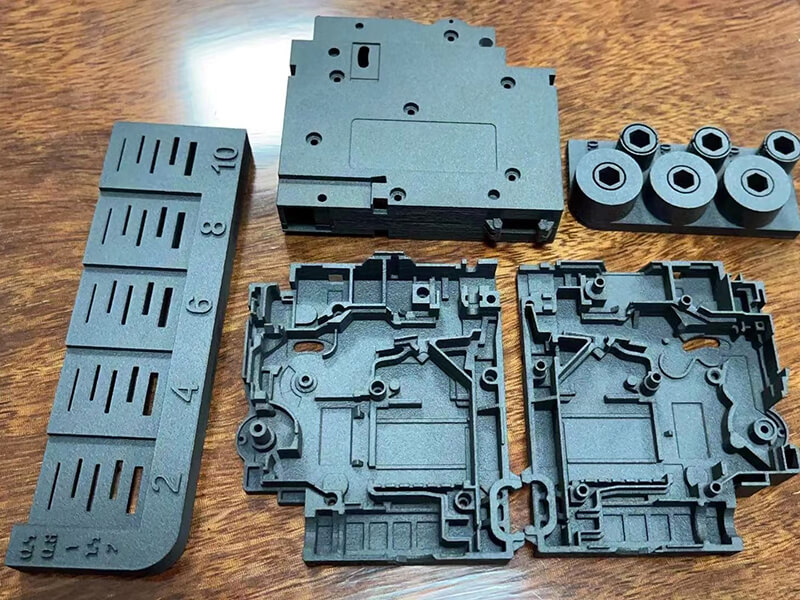

Prototyping companies offer to build small batches and one-off parts of product prototypes with CNC machining, 3D printing, etc in the shortest possible time.

When do you need a prototyping company?

Prototypes are needed for various purposes. You need a prototyping company when:

Testing and Evaluating

Sure you have a solid idea. But the actual product may differ from what you had in mind. Having a prototype will show you the practicability of your product.

Investor Pitches

A good prototype can demonstrate to the investors how your products work, and help them understand the actual value of it. Thus, it brings more business funding.

Market Research

Before launching a product it is better to test whether it works or not. A perfectly designed prototype can test the market determining what works and what does not.

Improvements

Small units of prototypes help decide on the good and bad parts, along with determining what materials to use.

Patent

For innovative products, a patent is necessary. It will protect you from duplicated products designed by other manufacturers. There are parent laws to ensure your products remain profitable.

How to Extract Benefits from a Prototyping Company?

Prototyping companies can simplify the process of your product development by:

Saving Cost

Prototyping tools are costly. Most start-ups don’t have the amount of capital to invest in those technologies. So, you can use prototyping companies for the latest manufacturing processes such as CNC machining, 3D printing, and sheet metal manufacturing without having to empty your wallet.

Saving Time

The prototype manufacturing process does not require tools. Advanced processes used for creating prototypes nowadays are mostly based on CAD files. Ensuring high precision and fast delivery.

Expert Knowledge

By ordering prototypes through prototype manufacturing companies, start-ups can get expert professionals whom they can rely on.

Flexibility

As the manufacturing process is toolless, you can easily return the drawings or CAD files for them to be changed. This allows businesses to improve their product design without being too costly.

Basic steps you should consider following when working with a prototype company

Now that you know what a prototyping company can do for you, let’s find out what you need to work with them:

A Basic Prototype

Sketch a basic prototype design of your idea by hand or use CAD software to create a visual design. Show the engineers your design and let them know the requirements.

Ask for a Fee Quote

Ask for a quotation on the company’s website or email them. Send them the details including the number of units required, the type of material to be used, and timelines. The company will let you know the full cost based on your requirements.

Sign an Agreement

Sign a nondisclosure agreement with the company. It will prevent the company from sharing them with others.

Get as much feedback as you can

Make sure that the prototyping company keeps you up to date with the progress. It will help you to ensure that the guidelines are followed and the engineers can immediately take action in case of any changes or improvements.

The Do’s and Don’ts of Prototyping

Do’s

Don’ts

Prototyping companies can be a lifesaver for small and medium manufacturing businesses. You only need to find out the perfect one to work with. And if you’re working with plastic materials, UV plastic can be the perfect fit for you!

Need A Trustworthy Rototyping Company

Click on the button, you will find the Trustworthy Rototyping Company for your project.