Polycarbonate Plastic Machining/Fabrication Service

Leading Supplier of Polycarbonate Plastic Machining and Fabrication Service In China

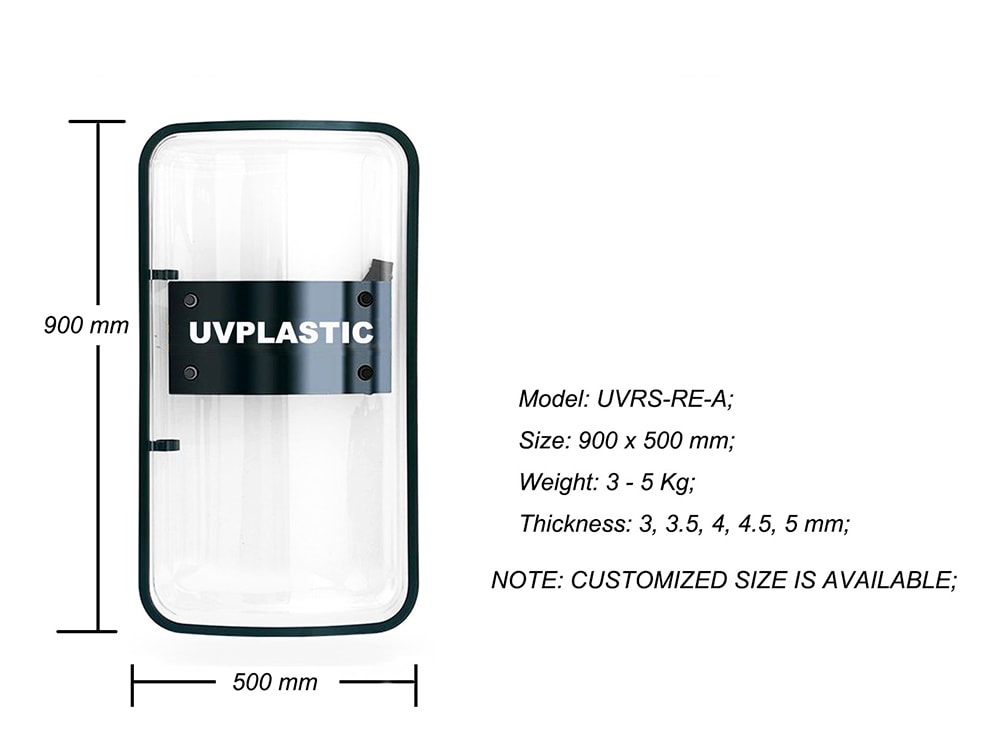

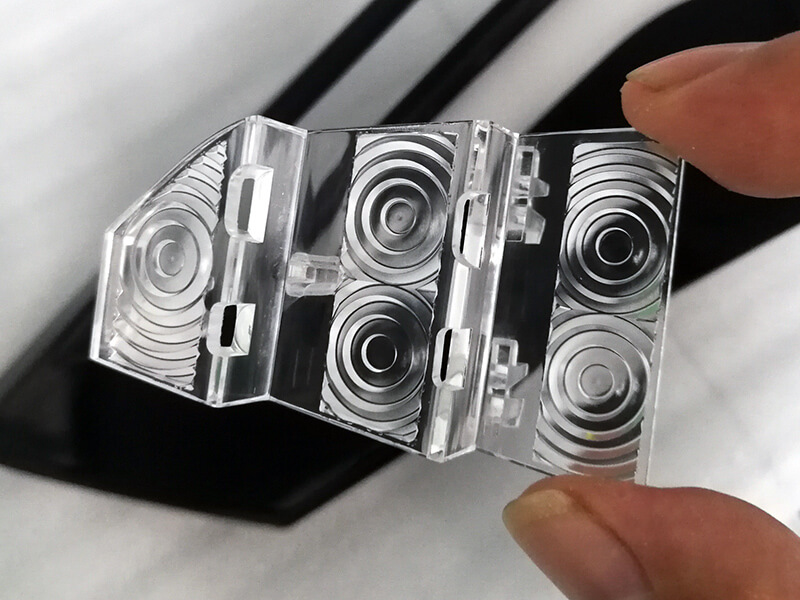

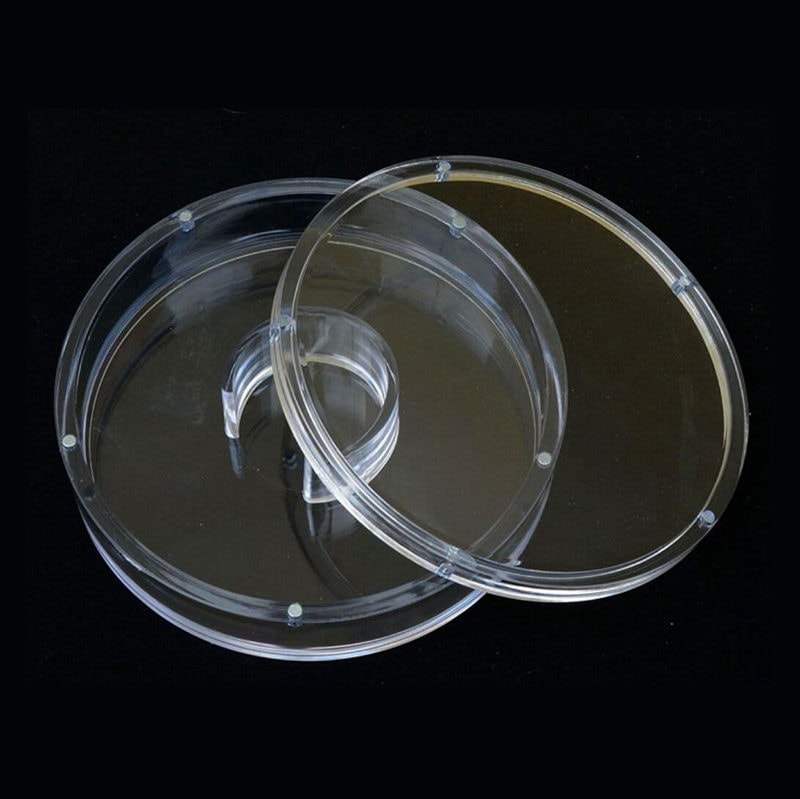

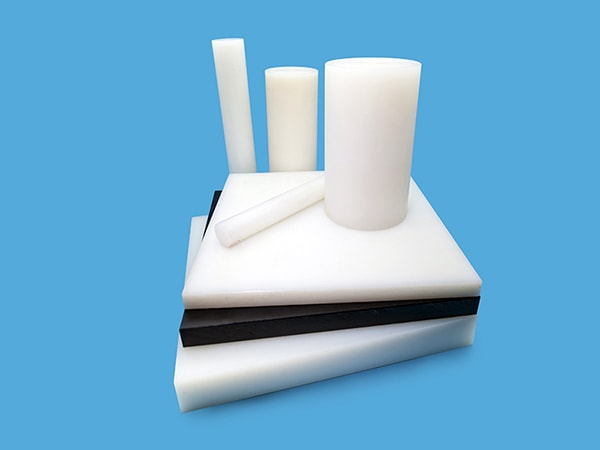

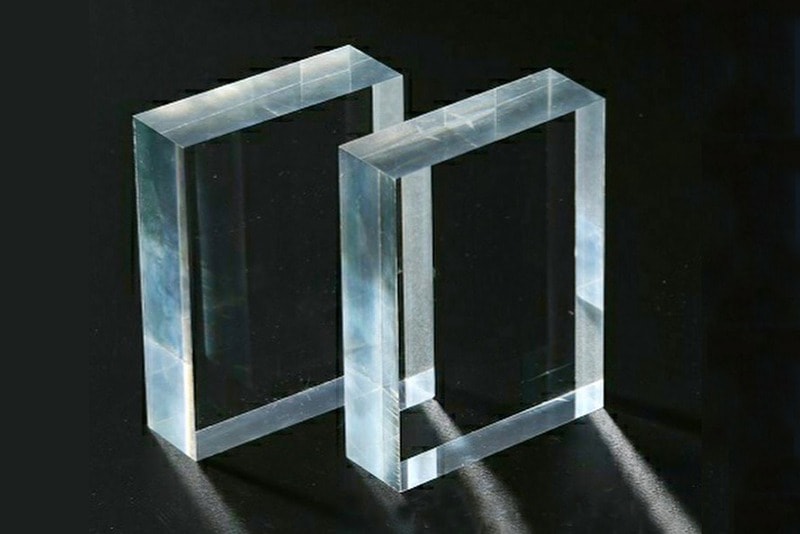

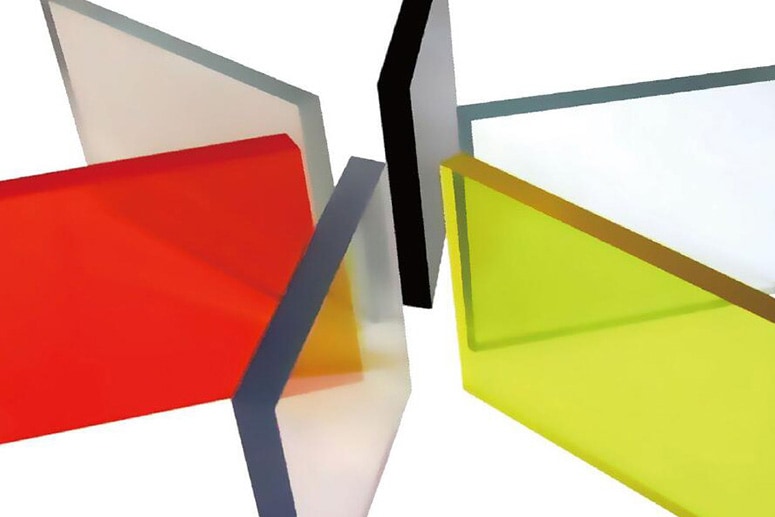

Since 2003, UVPLASTIC has been involved in Polycarbonate Machining and Fabrication Services in China. With more than 19 years of experience, we are providing integrated machining solutions for most plastic parts from prototyping to small volume production and large volume production. We can machine the following engineering materials: Polycarbonate, Plexiglass, POM, ABS, Nylon, PET, PETG, PVC, aluminum, etc.

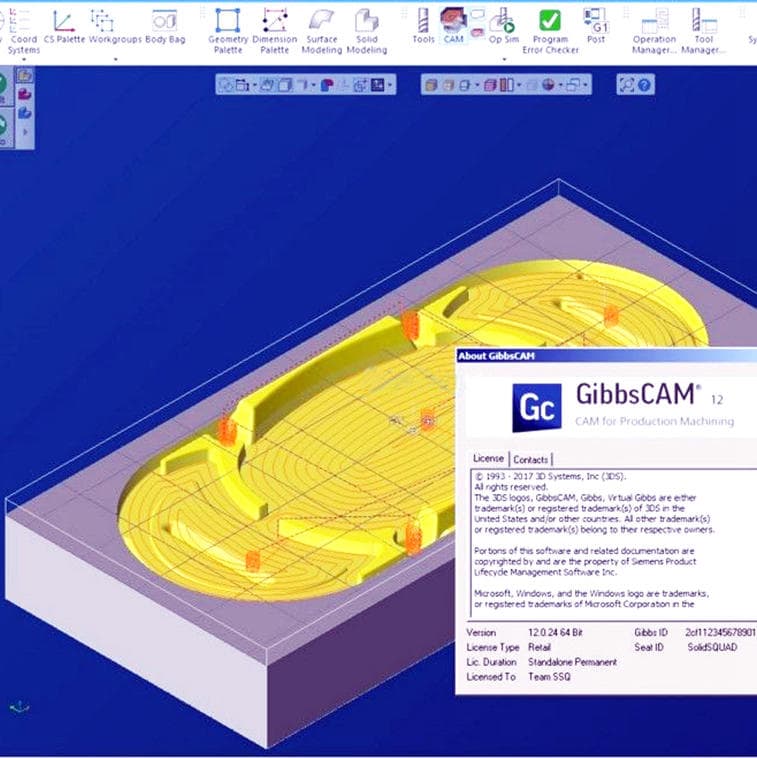

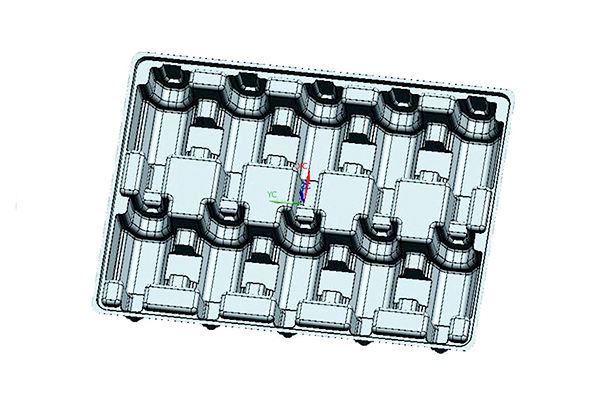

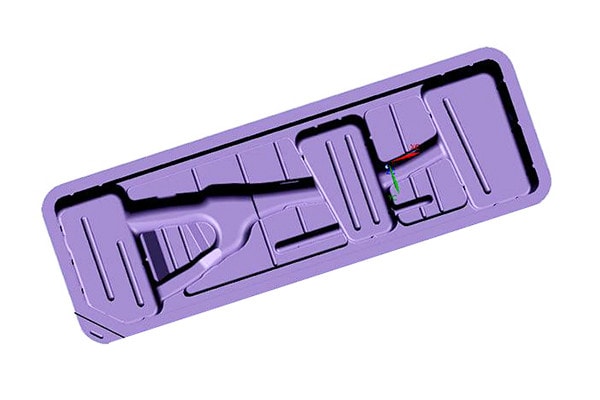

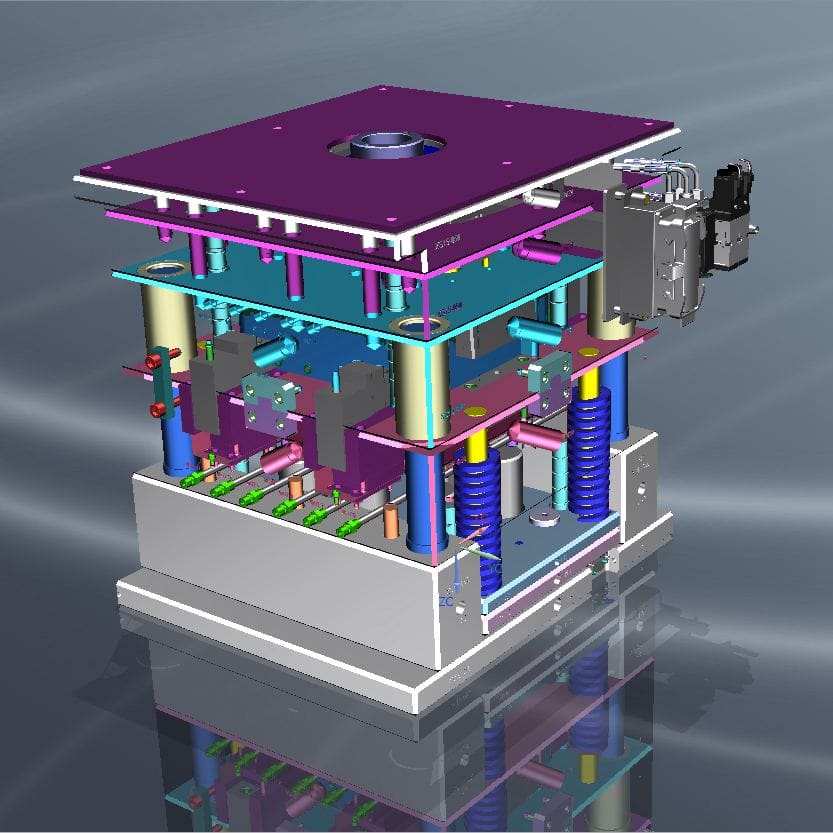

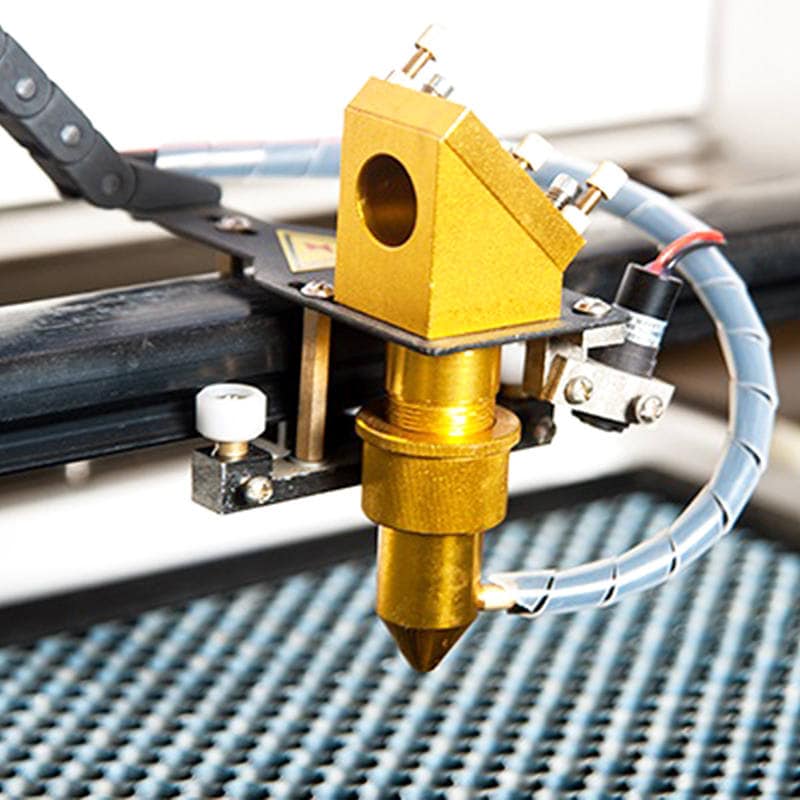

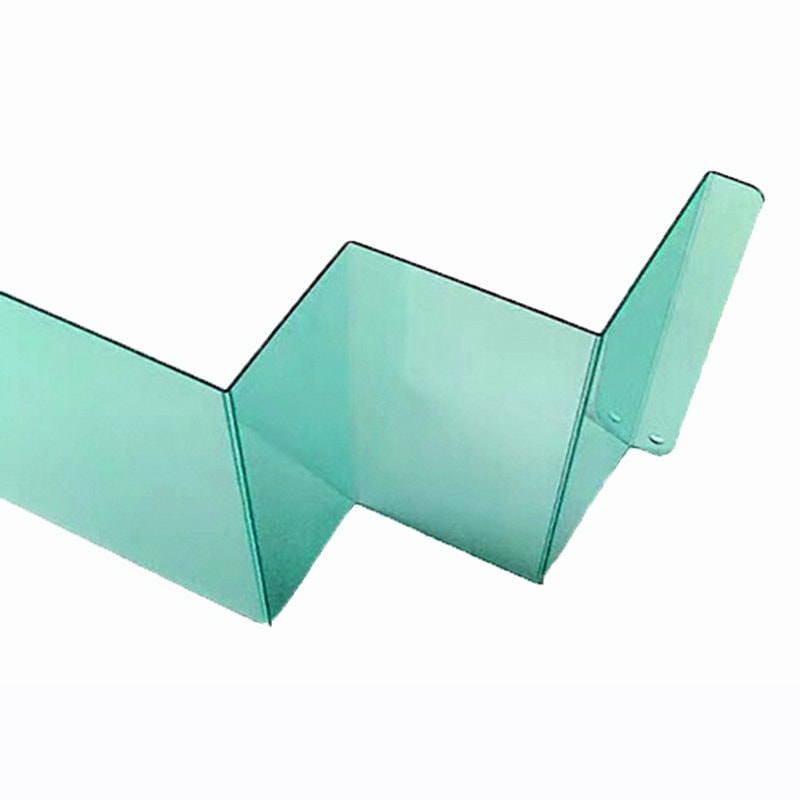

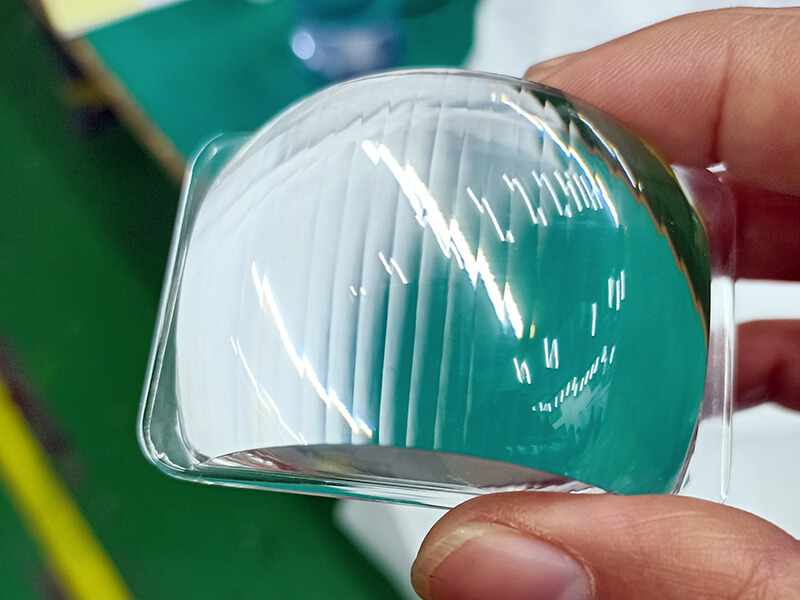

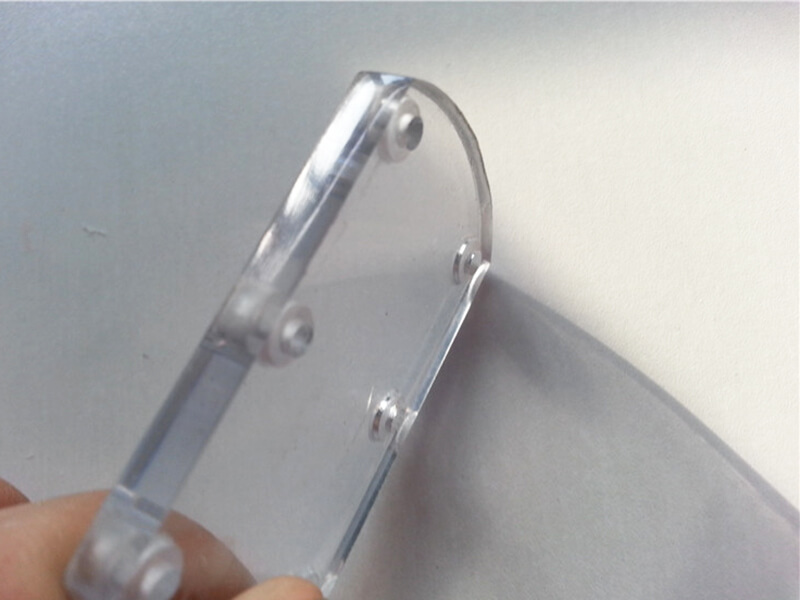

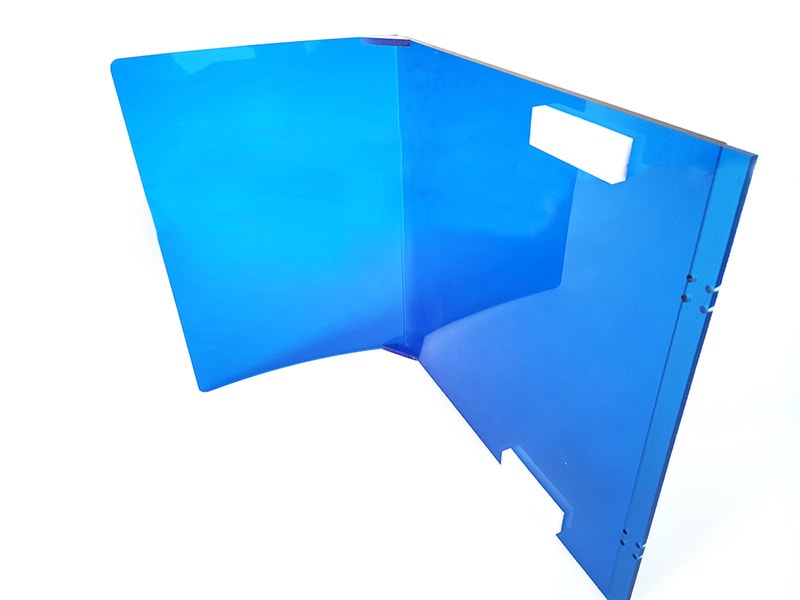

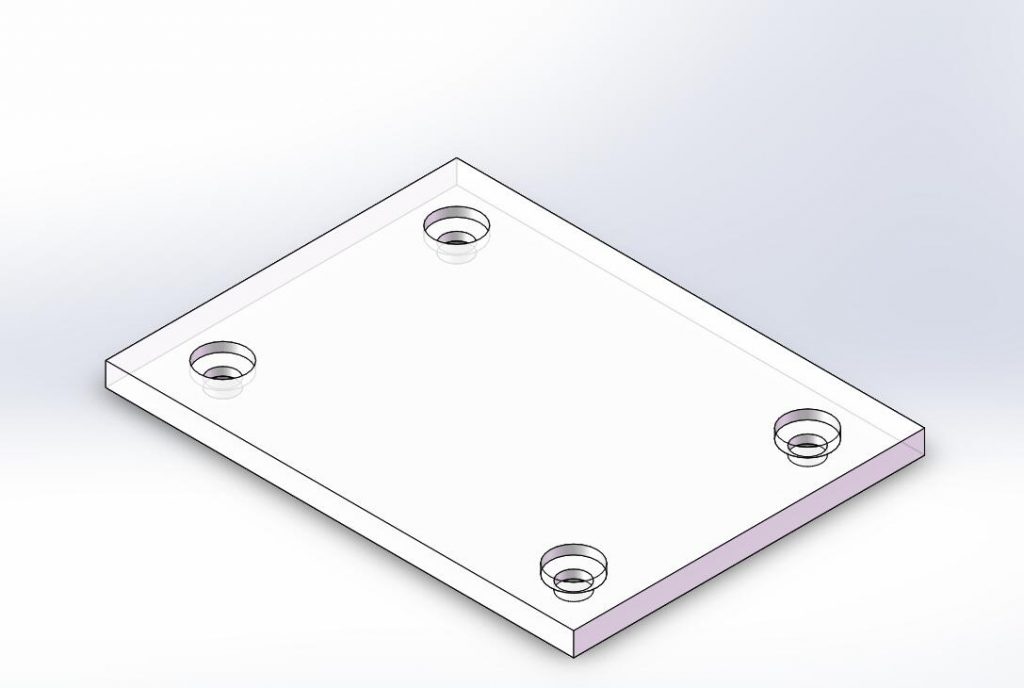

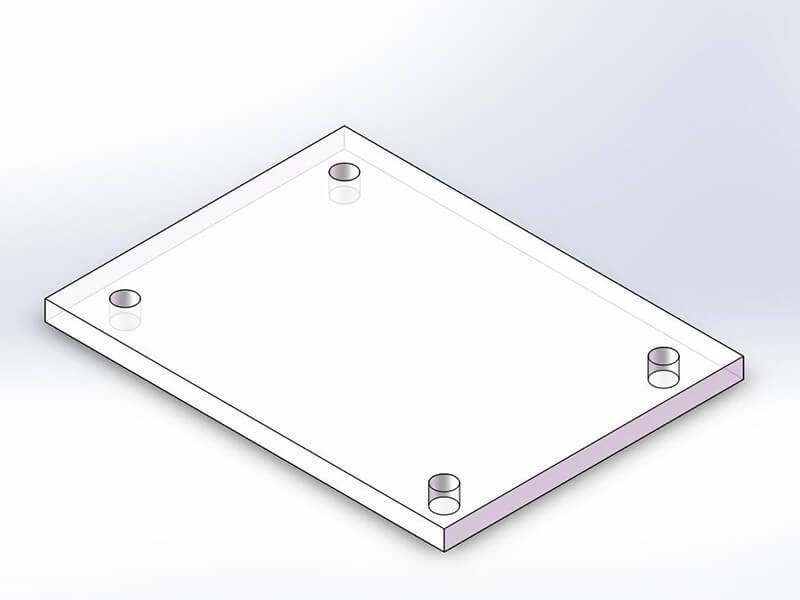

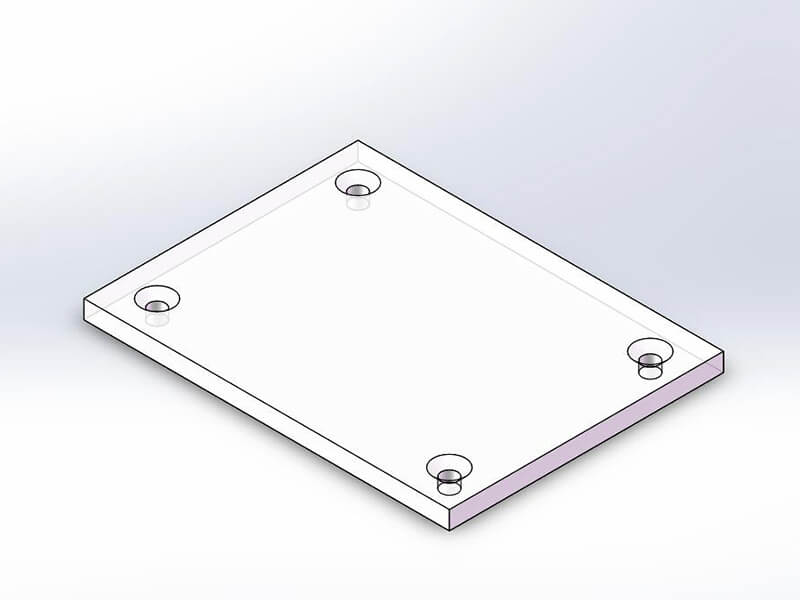

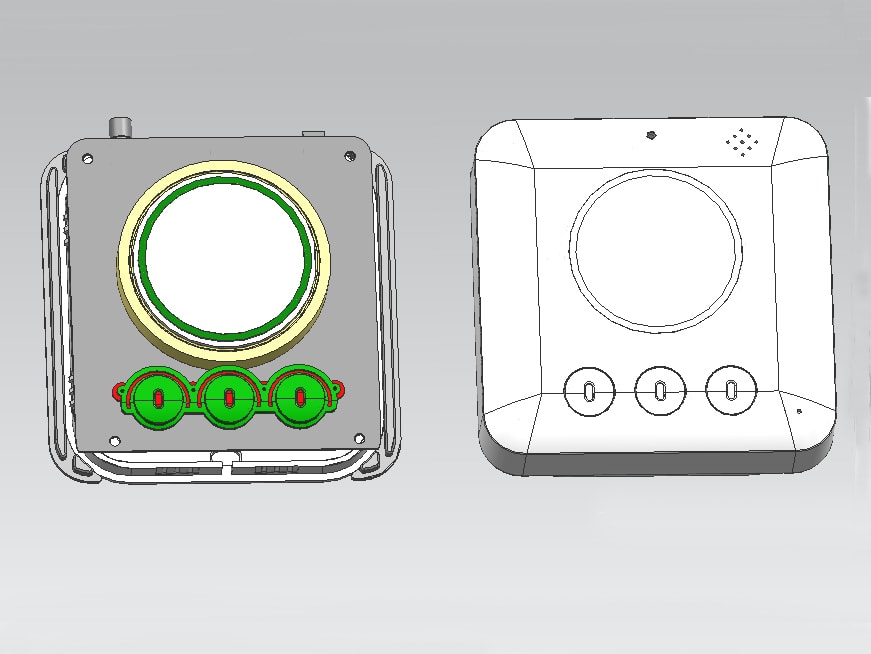

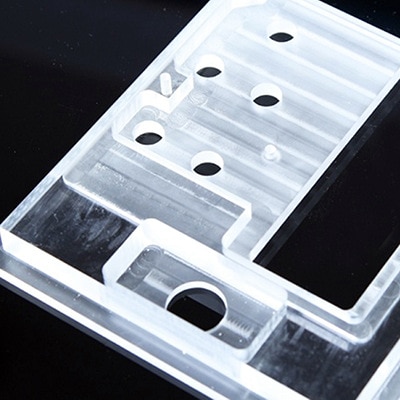

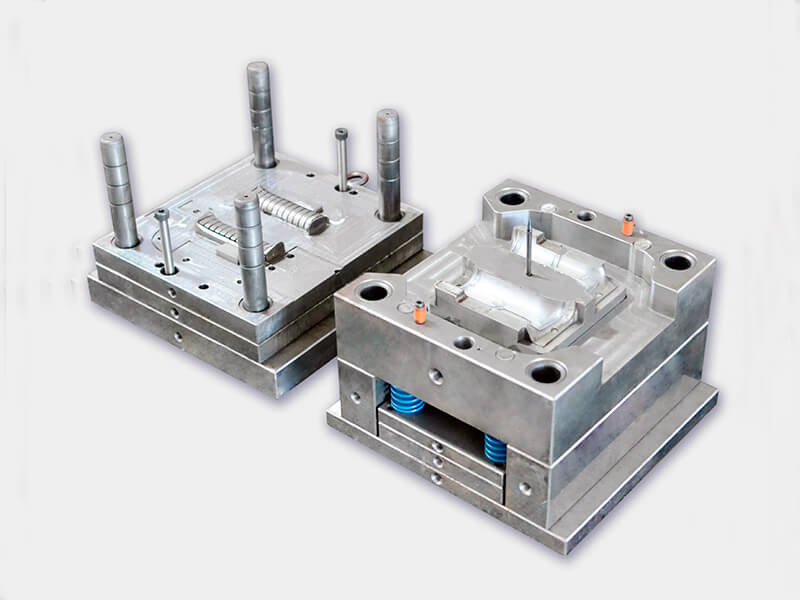

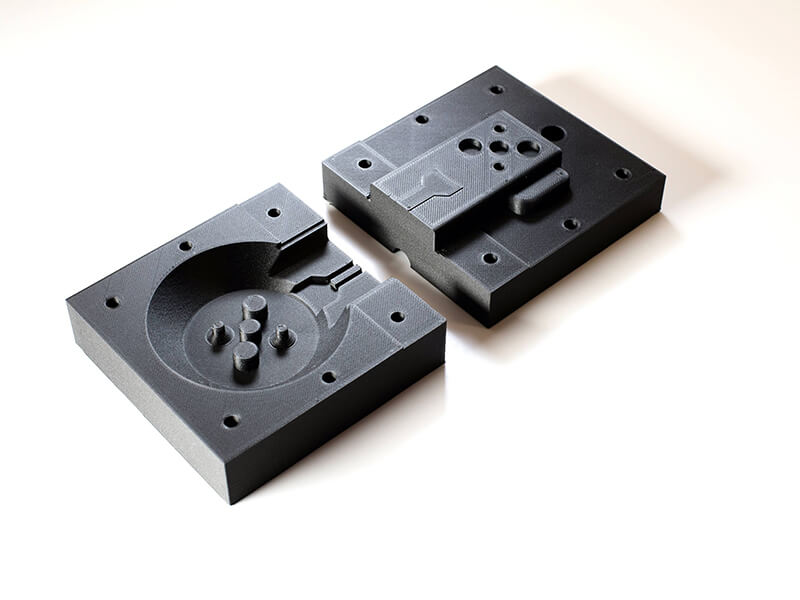

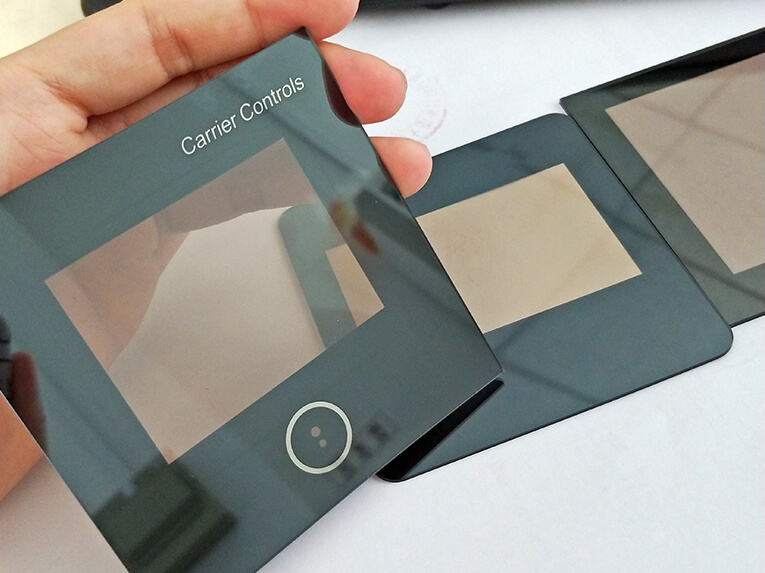

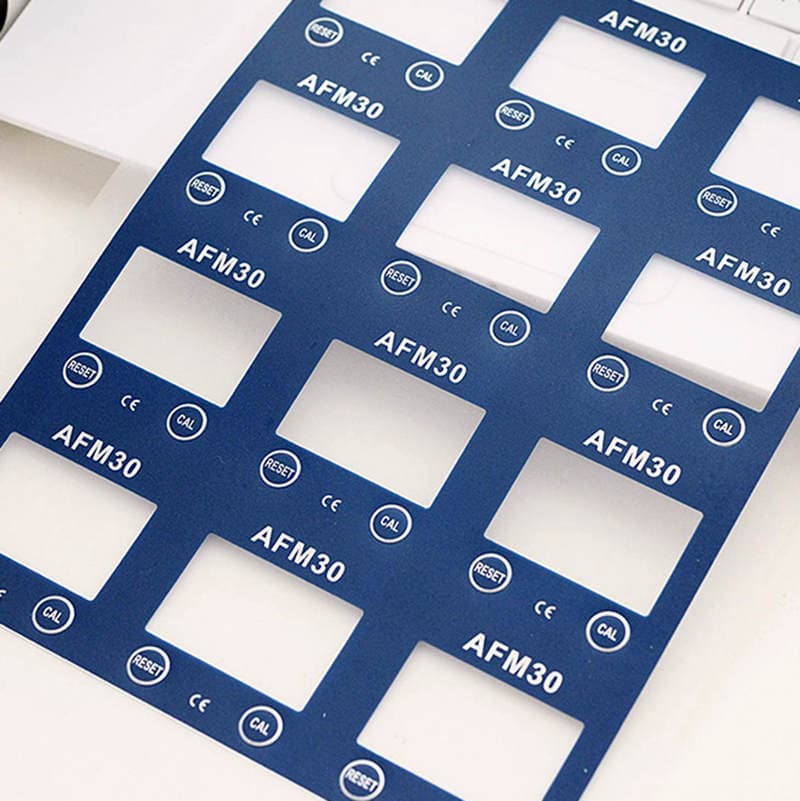

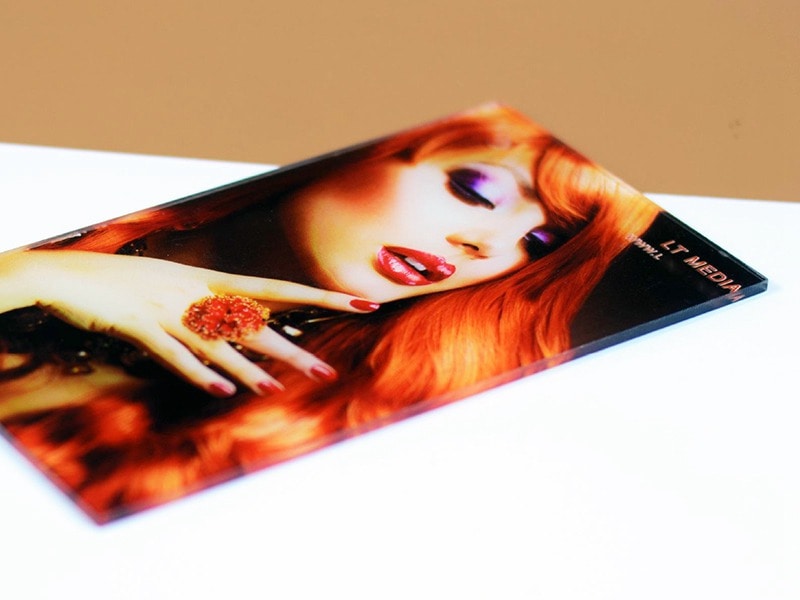

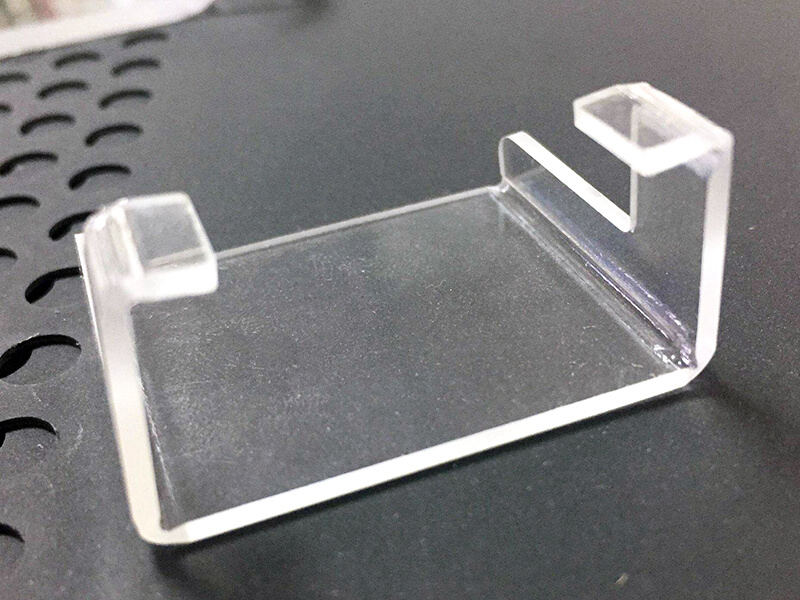

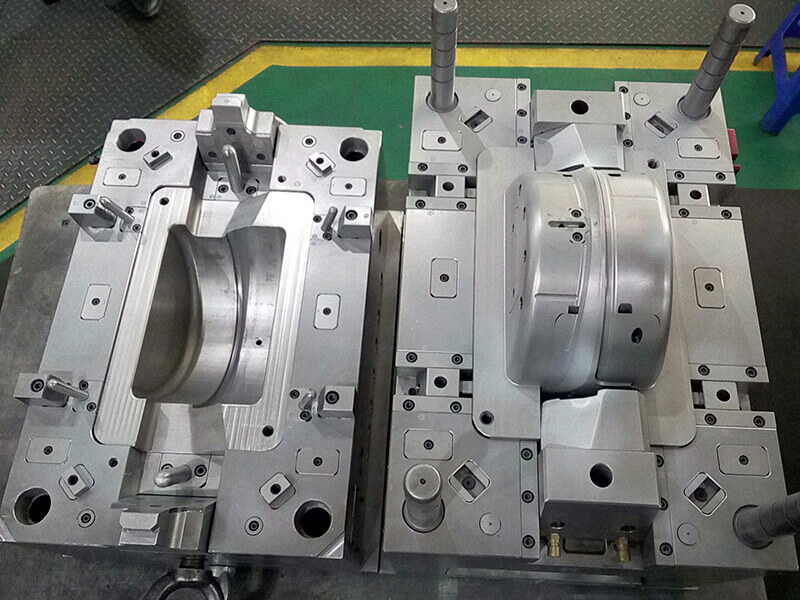

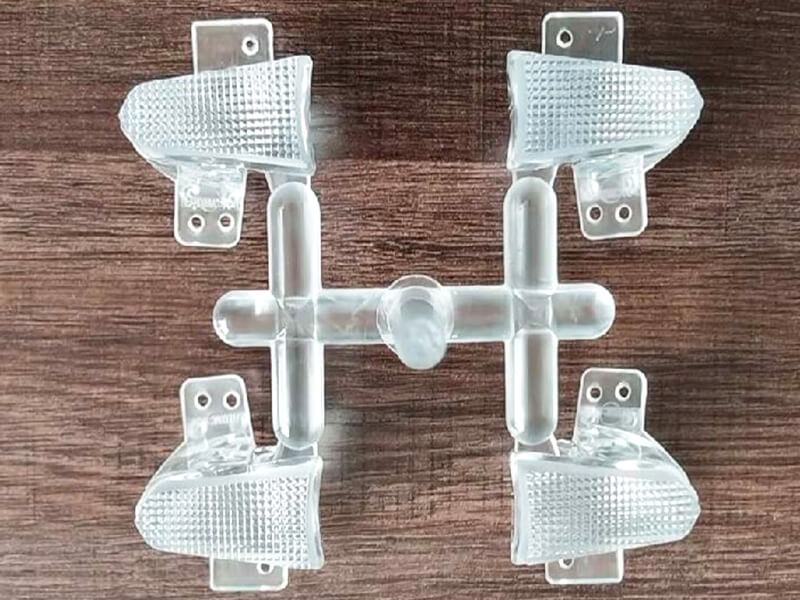

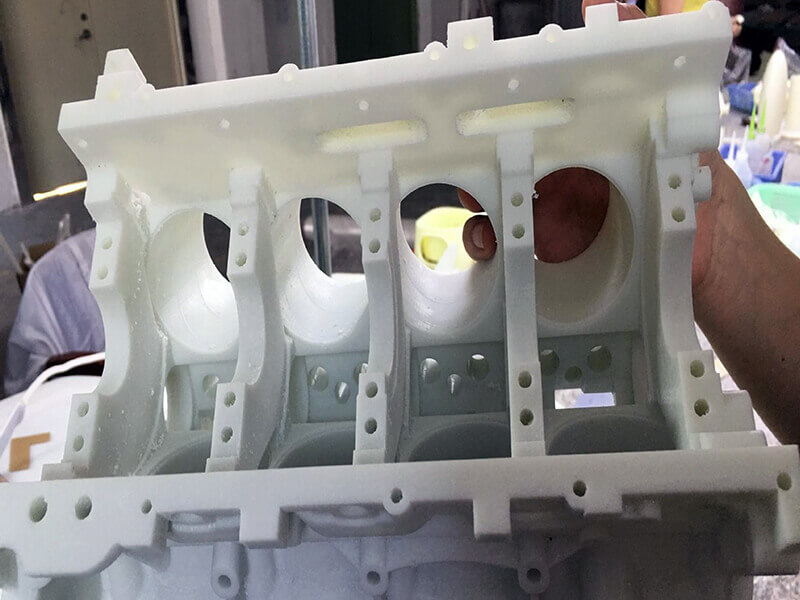

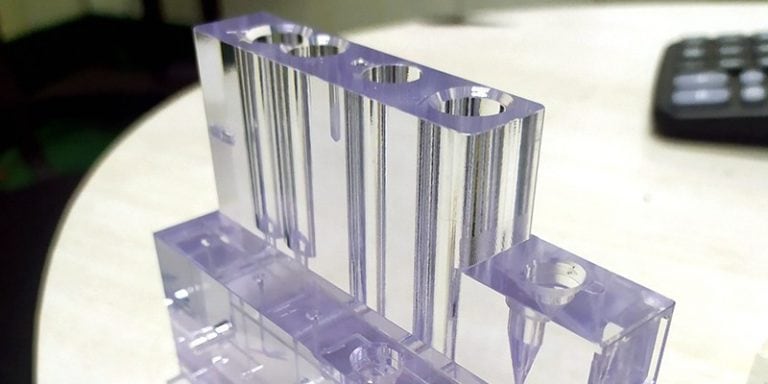

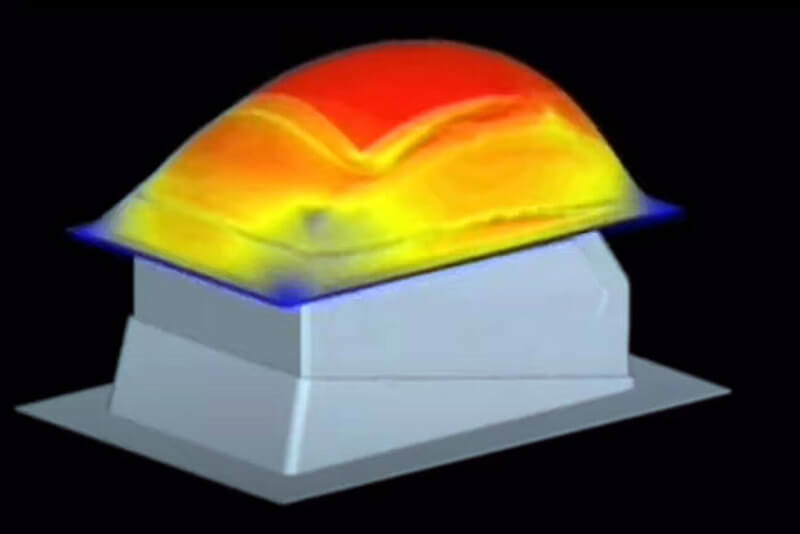

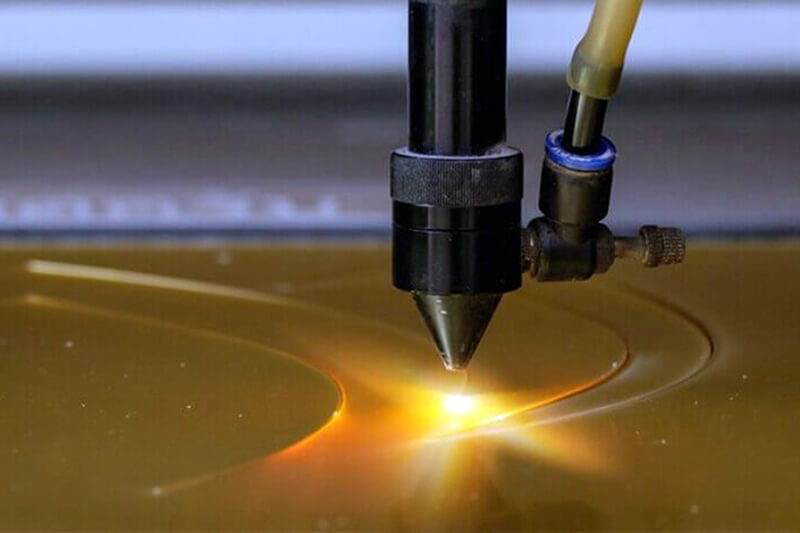

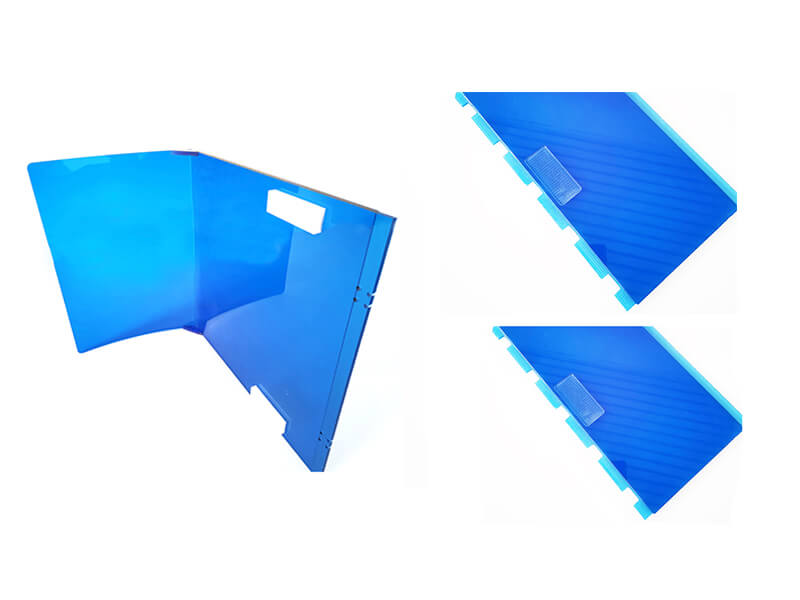

With the help of computer-aided design software, like CAD, Solidworks, UG, CATIA, and CAM, our engineers work with our clients to design plastic parts. Meantime, they can find the high cost-efficient machining solution to meet clients’ requirements. Normally, our machining methods include CNC machining, Vacuum Forming, Injection Molding, 3D printing, Cutting, Bending, Welding, Printing, Painting, Polishing, Electroplating, etc.

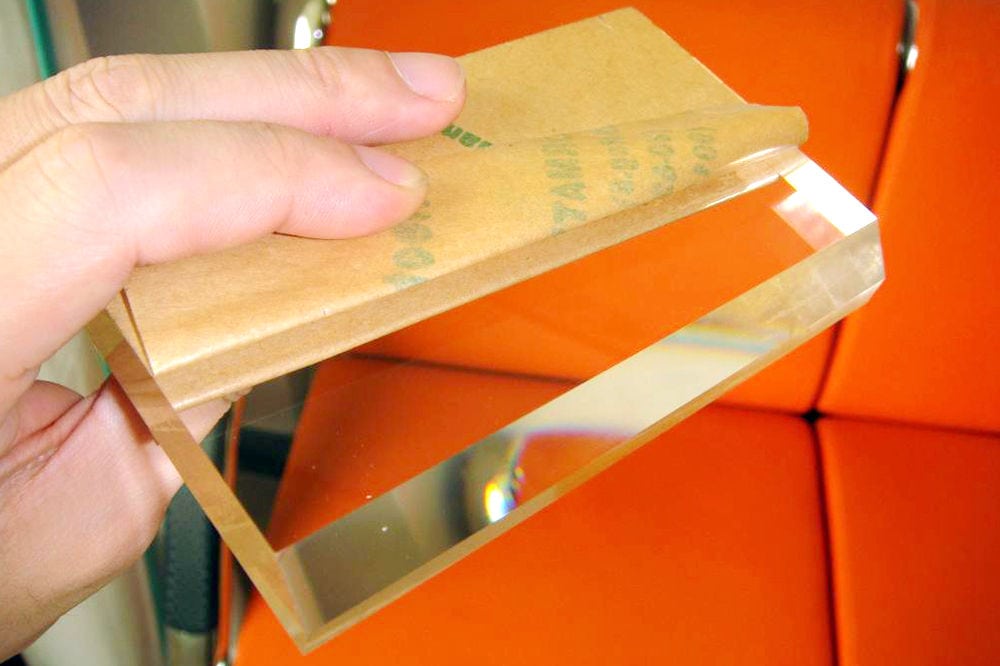

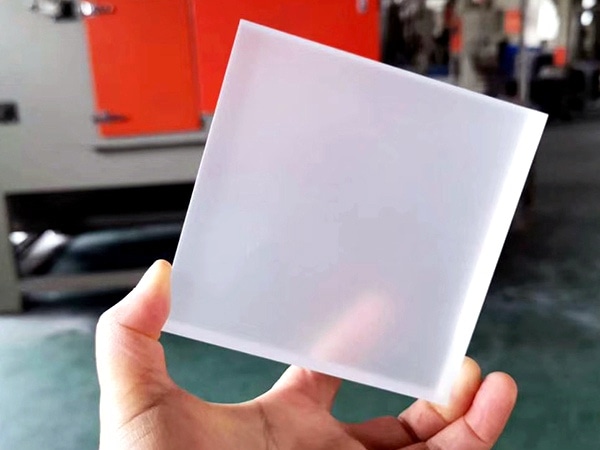

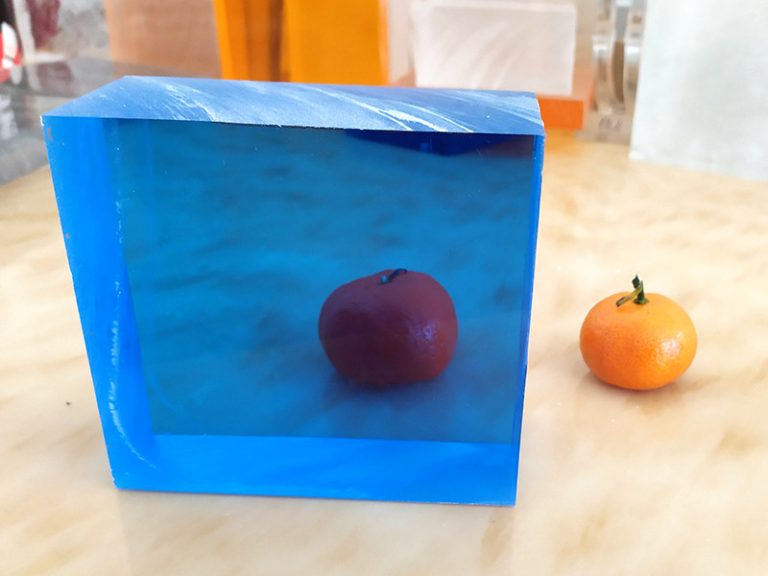

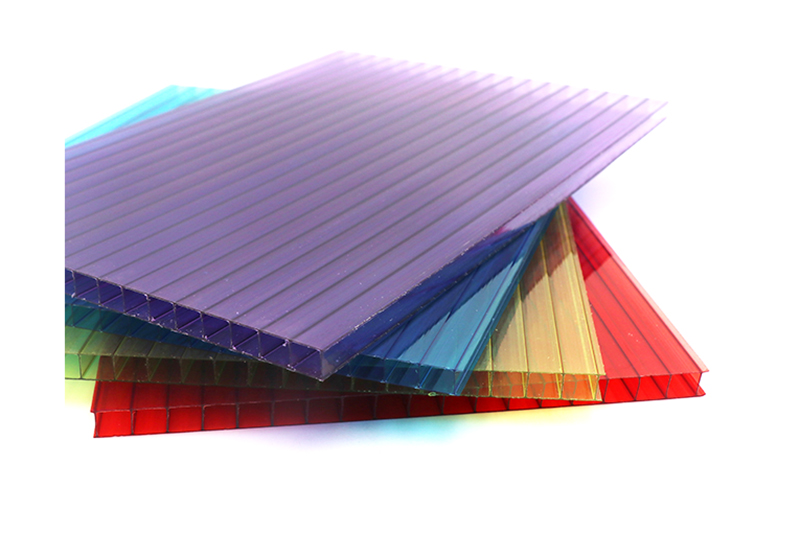

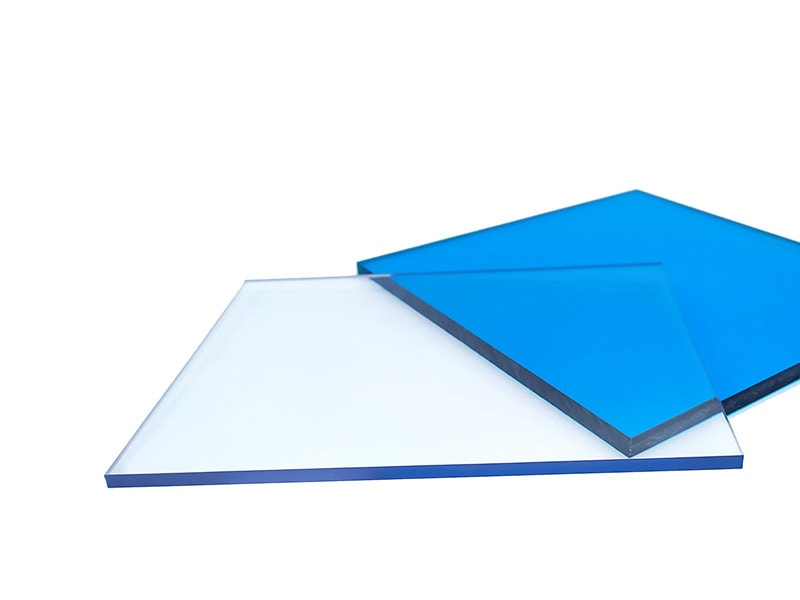

From Raw Material of polycarbonate To Finial Custom Parts

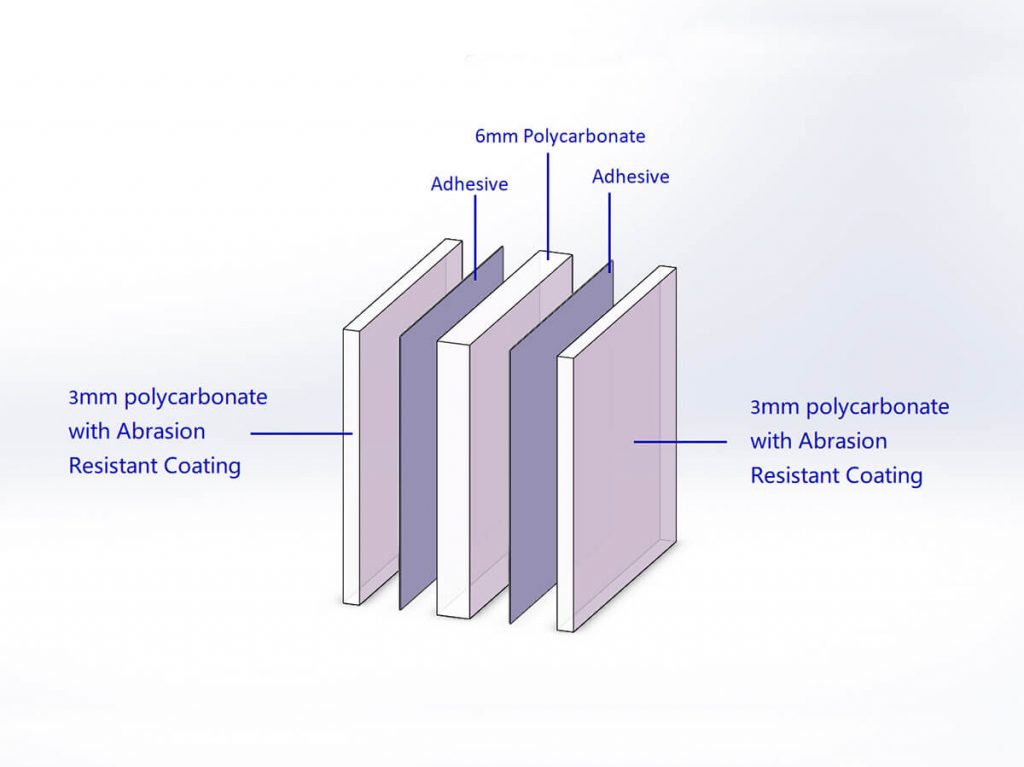

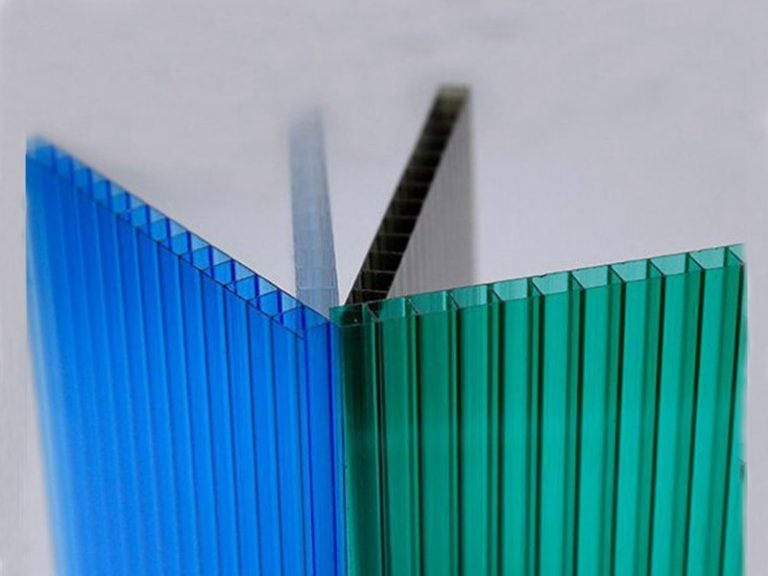

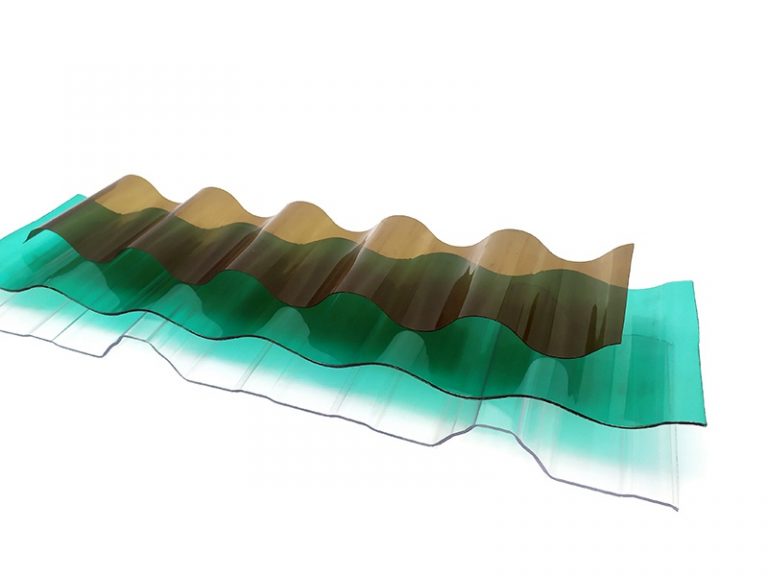

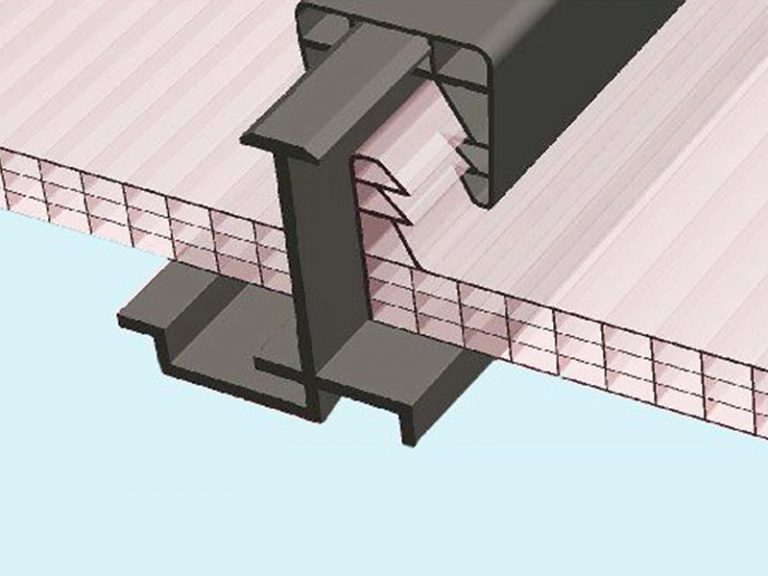

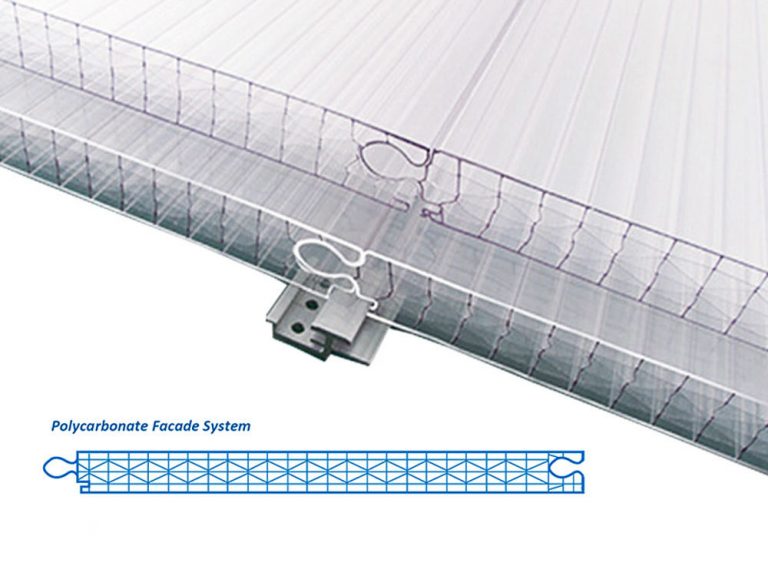

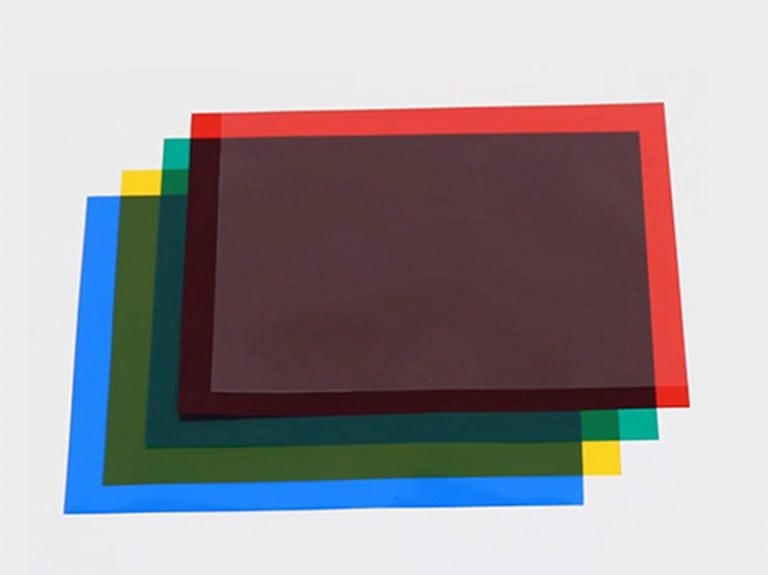

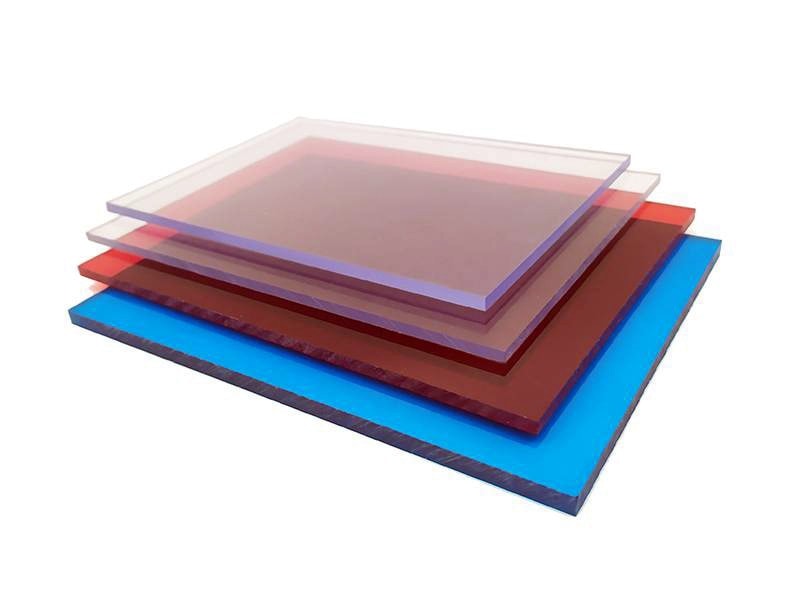

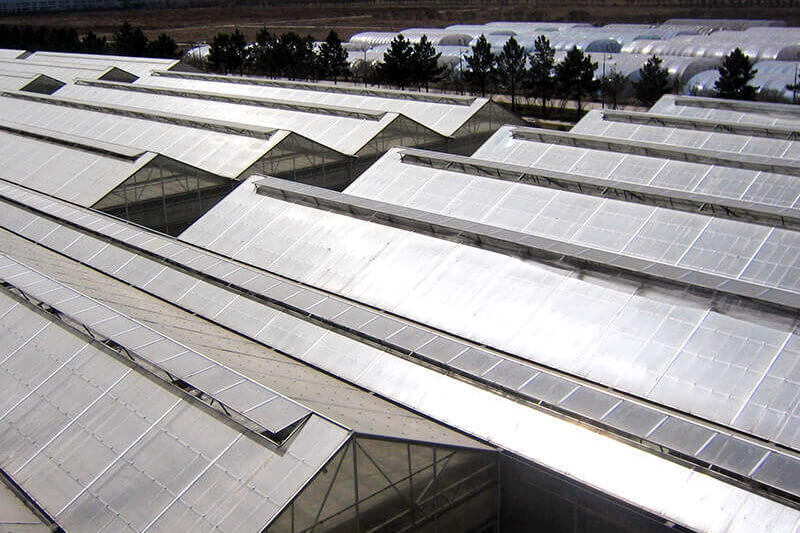

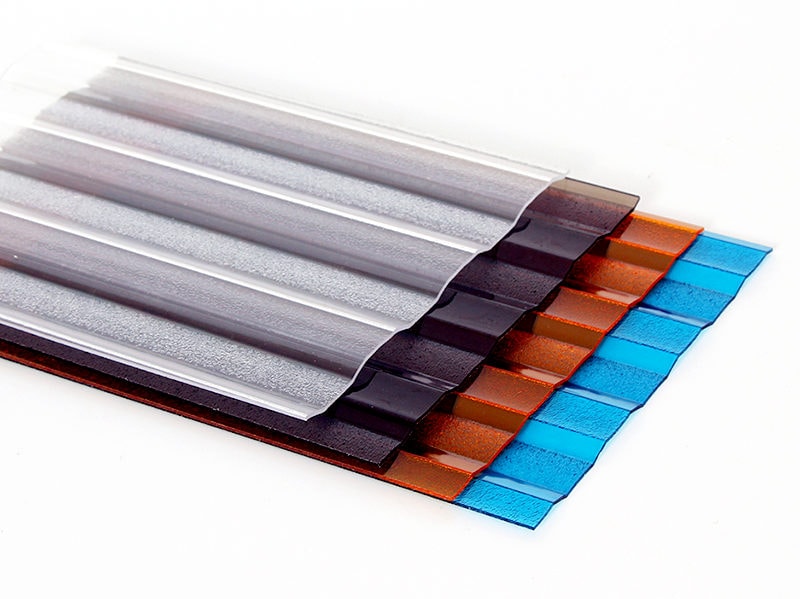

With the business growing, we built our own factory in 2007, and manufacture high-quality polycarbonate sheets by using raw materials from Sabic, Covestro/Bayer, MITSUBISHI, and TEIJIN. Therefore, we can control product quality from raw material to final plastic parts, meantime, offers a competitive price and excellent leading time. Sometimes, we buy polycarbonate sheets from Lexan and Makrolon according to clients’ requirements.

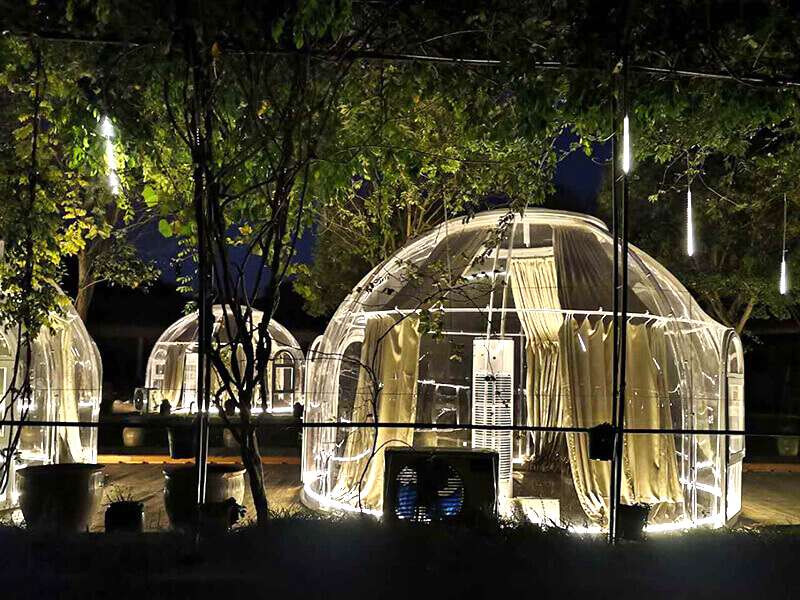

As a leading manufacturer of polycarbonate sheets and supplier of polycarbonate fabrication services in China, we are providing high-quality plastic parts from prototyping to volume production. Today, we are so honored to cooperate with more than 1200 clients from more than 56 countries all over the world, they are active in aerospace, architecture, medical industry, automation, packaging industry, automotive, tourism industry, sign&display, electric industry, decoration industry, etc.

Integrated Solution for Polycarbonate Plastic Machining and Fabrication Services

With more than 19 years of experience in polycarbonate plastic machining and fabrication services, UVPLASTIC understands the physical properties and processability, therefore we machine high-quality polycarbonate plastic parts with the most cost-efficient machining solutions. Here are some machining methods for custom polycarbonate products.

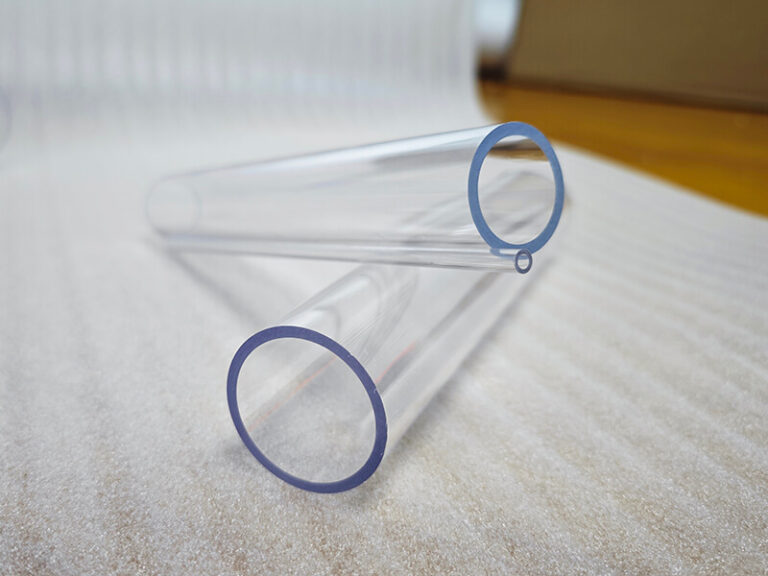

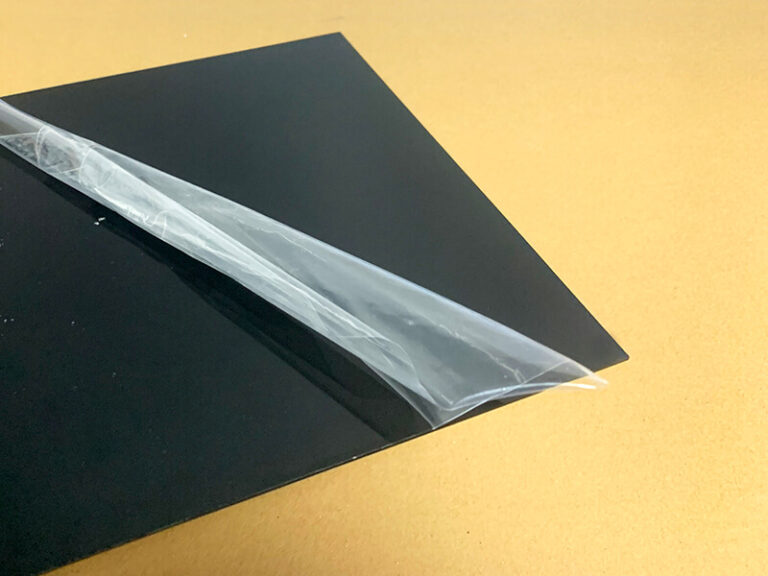

Related Products

Related Articles

Frequently Asked Questions

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.