The Difference Between Glass And Polycarbonate Facade System

When it comes to integrating daylighting into building facades, the emphasis must be on materials and systems to accomplish everything. There are two primary forms of material-based systems: popular, glass and polycarbonate facade systems.

Here in this article, we will focus on these two facade systems and try to understand which one is perfect for you.

What Is the Facade System?

The term facade is derived from the Italian word “Facciata,” which means “Outside” or “Any” of a building’s exterior faces. The term is often used to refer solely to a house’s main or front face. It is one of the most critical elements of a house, along with the roof, since it serves as the primary protection against external weather elements that could damage the structure’s health, such as rain, snow, wind, frosts, and sunlight.

It’s critical to choose a facade system that protects against these dangers while also lowering energy usage, and maintenance costs and improving occupant comfort.

A facade system is a form of cladding with a ventilated chamber between the cladding and the insulation, preventing thermal bridging and condensation. This provides excellent thermal efficiency while also lowering humidity levels.

Application of Facade System

Façade systems are becoming a more critical feature of architecture as the need for low-maintenance exteriors for commercial and residential buildings grows.

Facade systems made of composite, stone, and wood are also common, as they are environmentally friendly and long-lasting.

According to the manufacturers’ requirements, here are some of the facade system’s applications.

Facade Systems With Composite Panels

Composite panels are large-format facade panels that are made up of stable core material and two covering layers. They are highly elastic due to their composite construction, allowing architects to construct imposing architectural designs that match the building’s contours and can even be rounded.

Facade Systems With Fibre Panels

A fiber panel is a large-format, thin-walled facade panel made of cement with fiber materials for added stability. These components can be supplied as thoroughly dyed panels due to their homogeneous structure. Colors can be adjusted to suit your needs.

Facade Systems With Metal Panels

In ventilated curtain walls, a variety of metal materials can be used. Color-coated aluminum and steel profiles are the most common, but high-quality natural-color materials like copper and zinc are also popular. Metal cladding is usually mounted in panels or fluted sheets, although simple sheet panels – riveted or fastened on the backside – are often used.

Facade Systems With Ceramic Panels

Ceramic panels for ventilated curtain walls are made from the same raw materials as traditional ceramic tiles, such as those found in wet areas like bathrooms. Facades, on the other hand, often use broad format sections.

Facade Systems With Tiles

Natural clays are used to create tile panels. The raw material is combined, extruded, sized, and shot. Long-term exposure to a high kiln temperature results in intense colors and high intensity.

Facade Systems With Natural Stone

Since ancient times, natural stone cladding has been used in facades and exterior walls. For ventilated facades, stone with a thickness of 30-40 mm is commonly used.

Thinner products, on the other hand, maybe used with adhesive fastening techniques. Granite and travertine are natural stones that can be used in facades.

Glass Vs Polycarbonate Facade System

Aesthetics aren’t the only consideration when deciding whether to use glass or polycarbonate. Consider the following significant features when comparing polycarbonate and glass facade system:

Strength and Lightweight

When it comes to strength, polycarbonate allows you to get the best of both worlds. It’s 200 times stronger than glass and more than half the weight, all without sacrificing natural light transmission or visibility. Besides, the polycarbonate facade system carries 50% less weight than glass.

Heat Resistance

Polycarbonate can withstand temperatures of around 270°f for several hours or sudden bursts of heat of up to 1166°f without distortion, breakage, or heat absorption.

Traditional glass can’t withstand high temperatures and absorbs heat, making it challenging to handle and increasing the risk of it shattering.

Optimal Thermal Insulation

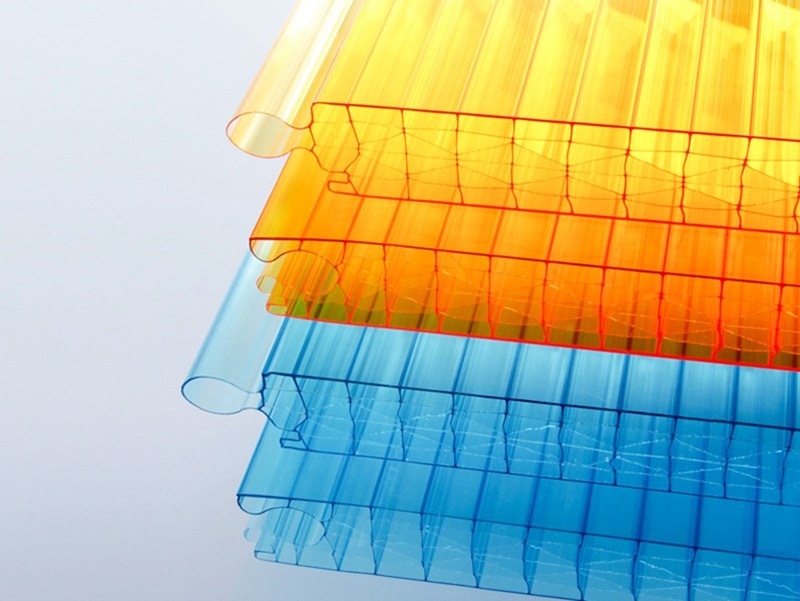

Thermal insulation isn’t just a good to have; it’s a must. Polycarbonate provides more than 20% stronger insulation than its glass equivalent. A double-glazed glass (16mm) provides 2.7 w/m2.⚬k insulation whereas seven walls multiwall polycarbonate (16mm) provide 1.7 w/m2.⚬k

Energy Costs

Higher u-value materials are weak insulators and allow more heat to escape. Thicker sheets provide more excellent insulation and less heat loss with a lower u-value.

Using a polycarbonate facade reduces energy costs significantly, both for heating in the winter and air conditioning in the summer. Glass facade is far behind polycarbonate.

UV Radiation Protection

When it comes to transparent roofing, providing adequate exposure to ultraviolet (UV) solar radiation is more important than ever before, particularly for applications like pool covers and pergolas.

Although sunscreen provides adequate protection, the polycarbonate facade system, which entirely blocks UV radiation, is the most potent barrier.

Control Over Light Transmission and Diffusion

Polycarbonate can be shaded to emit a certain percentage of light while also blocking UV and solar heat. But the glass facade system has some issues like leaking and allowing direct sunlight into the building.

Lifespan

Polycarbonate sheet has a long lifetime due to its durability, impact resistance, and heat resistance, lowering the cost of replacement. Glass is prone to breakage and damage, requiring more frequent replacement, mainly when using thin panels.

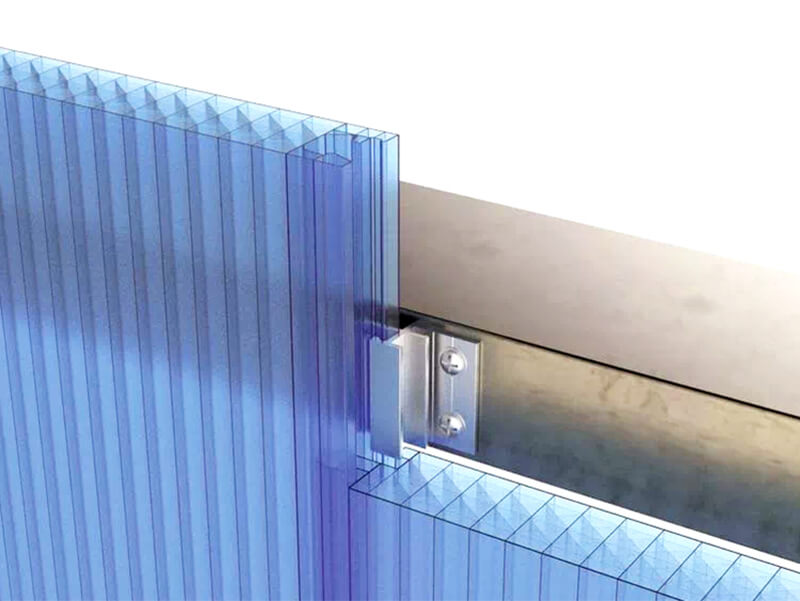

Ease of Installation

Polycarbonate eliminates the design limitations imposed by the glass, making curved designs simple and easy to implement. Since installers can use cold bend a polycarbonate panel on-site during construction, it removes the need for costly glass roll-forming, eliminates butt joints, and allows single-length sheets to be used.

Which One Should You Buy?

According to our analysis of a reliable and durable facade solution, polycarbonate is the better option. It outperforms glass in terms of providing good lighting and heat retention. Besides, it is virtually unbreakable, easy to machine, and requires low maintenance cost.

So polycarbonate is the way to go if you’re looking for a reliable and long-lasting facade solution for your home.