Flame Retardant Polycarbonate Film

Product Description

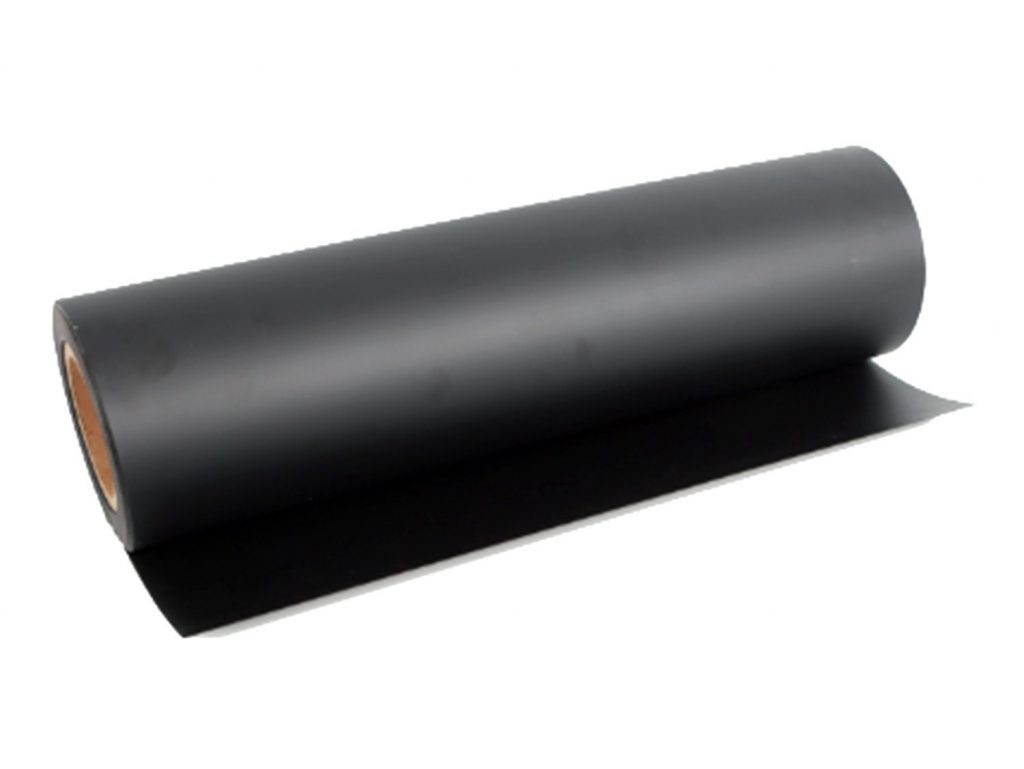

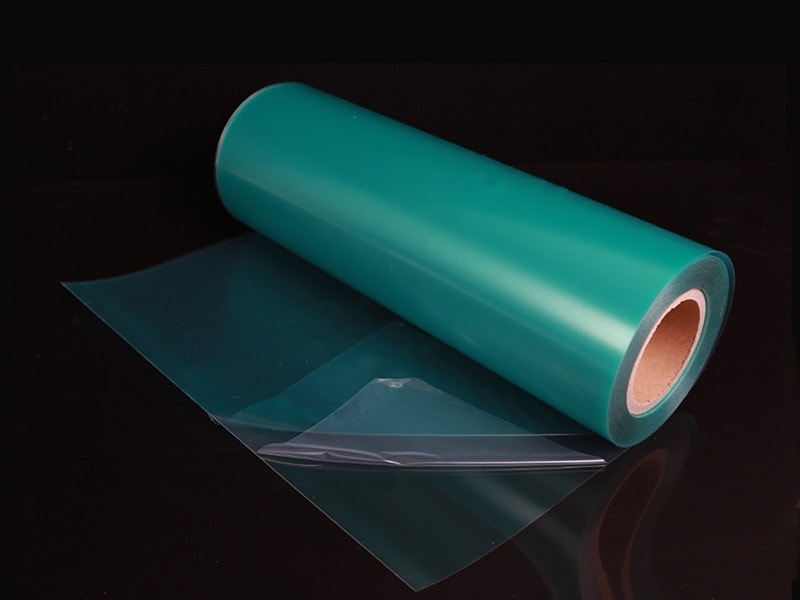

Flame Retardant Polycarbonate Film totally meets V-0/UL94 and VTM-0/UL94. The model is UVTPC-FL, it is no Halogen (no chlorine or bromine) flame retardant films. It can be packaged as panels and rolls.

UVPLASTIC Flame Retardant Film offers a variety of surface types including gloss/gloss, matte/gloss, velvet/gloss, velvet/matte. And the colors can be transparent, translucent, opaque. Otherwise, custom colors are available, the thicknesses are from 0.05 mm to 1 mm.

It is easily thermoformed, hydroformed, molded, die-cut, folded, and bent. It is the right material for wide applications in the auto industry, solar energy, consumer electronics, cloud data centers, telecommunications, etc.

Product Specification

Flame Retardant Polycarbonate Rool

| Thickness (mm) | Width (mm) | Length (m) | FL21 | FL41B | FL42 | FL42B | FLH11 | FLH21 | FLH42 | FLH42B |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 1220 | 500 | ✔ | |||||||

| 0.125 | 1220 | 400 | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 0.15 | 1220 | 400 | ✔ | ✔ | ||||||

| 0.175 | 1220 | 350 | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 0.2 | 1220 | 300 | ✔ | ✔ | ||||||

| 0.25 | 1220 | 300 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 0.3 | 1220 | 250 | ✔ | ✔ | ||||||

| 0.375 | 1220 | 200 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 0.43 | 1220 | 175 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 0.5 | 1220 | 150 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 0.76 | 1220 | 100 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 1 | 1220 | 80 | ✔ | ✔ | ✔ | ✔ |

Note:

- Polycarbonate fabrication services are available;

- Free to polycarbonate cut to size;

- Custom sizes are available;

Product Range

| Model | Surface Type | Thickness (mm) | V-0, VTM-0, VTM-2 | Transparet | Translucent | Opaque/Black | Remark |

|---|---|---|---|---|---|---|---|

| UVTPC-FL21 | Matte / Polished | From 0.1 to 2 | ✔ | ✔ | No Halogen (no chlorine or bromine) | ||

| UVTPC-FL41B | Velvet / Polished | From 0.25 to 0.76 mm | ✔ | ✔ | No Halogen (no chlorine or bromine) | ||

| UVTPC-FL42 | Velvet / Matte | From 0.125 to 1 | ✔ | ✔ | No Halogen (no chlorine or bromine) | ||

| UVTPC-FL42B | Velvet / Matte | From 0.125 to 0.76 | ✔ | ✔ | No Halogen (no chlorine or bromine) | ||

| UVTPC-FLH11 | Polished / Polished | From 0.125 to 1 | ✔ | ✔ | |||

| UVTPC-FLH21 | Matte / Polished | From 0.125 to 1 | ✔ | ✔ | |||

| UVTPC-FLH41 | Velvet / Polished | From 0.25 to 0.76 | ✔ | ✔ | |||

| UVTPC-FLH42 | Velvet / Matte | From 0.25 to 0.76 | ✔ | ✔ | |||

| UVTPC-FLH42B | Velvet / Matte | From 0.25 to 0.76 | ✔ | ✔ |

Custom surfaces are available upon request, subject to a minimum order.

Please contact the local distributor or send E-mail to [email protected]

Physical Properties

| Physical Properties | Value | Unit | Test Method |

|---|---|---|---|

| Density | 1.32 | g/cm3 | ISO 1183 |

| Haze | <0.5 | % | ASTM D1003 |

| Light Transmission | 89 | % | ASTM D1003 |

| Tensile Strength | 60 | MPa | ISO 527 |

| Elongation | <50 | % | ISO 527 |

| Bend Strength | 90 | MPa | ISO 178 |

| Tensile Modulus | 2300 | MPa | ISO 178 |

| Surface tension | ≥34 | dyn/cm | Test fluid |

| Dielectric Constant | 3 | – | IEC60250 |

| Resistant Puncture Voltage | 30 | MV/mm | IEC 60243 |

| Surface resistivity | 1.00E+16 | Ω/square | IEC 60093 |

| Volume resistivity | 1.00E+17 | Ω-cm | IEC 60093 |

| Coefficient of Thermal Expansion | 5.8 | ×10-5/℃ | ISO 11359 |

| Thermal Conductivity Rate | 0.2 | W/(m*K) | ASTM D5470 |

| Thermal Shrinkage | 0.5~0.7 | % | ASTM D1204 |

| Tg | 152 | ℃ | ISO306 |

| Grade of resistant flame | V-0, V-2, VTM-0, VTM-2 | / | E249605 |